Electric tool

A power tool, motor-driven technology, applied in the direction of manufacturing tools, portable mobile devices, etc., can solve the problems of user hand damage, precise adjustment of processing direction, workpiece processing failure, etc., to improve user experience, ensure processing accuracy, and reduce negative effects. effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

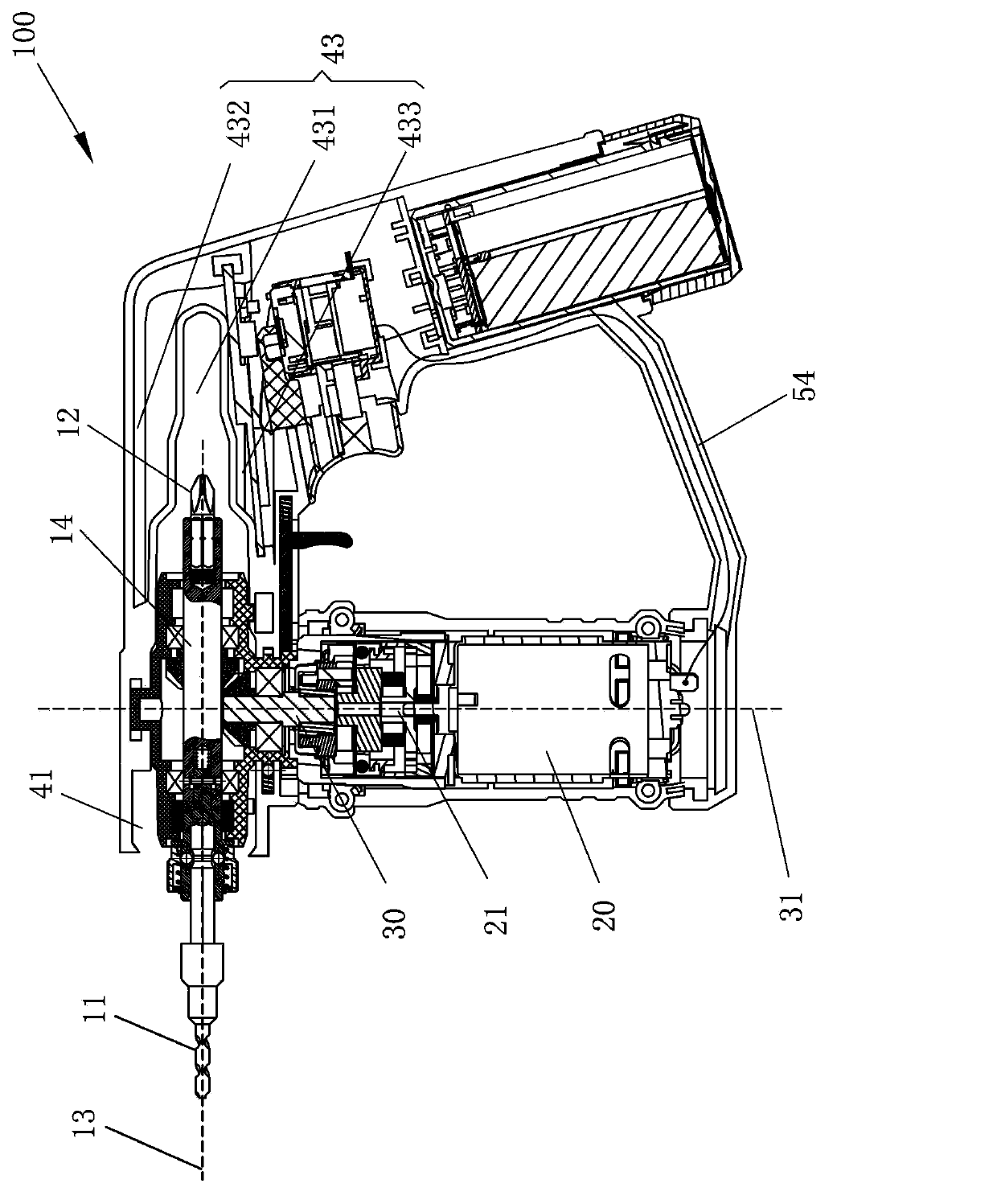

[0030] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

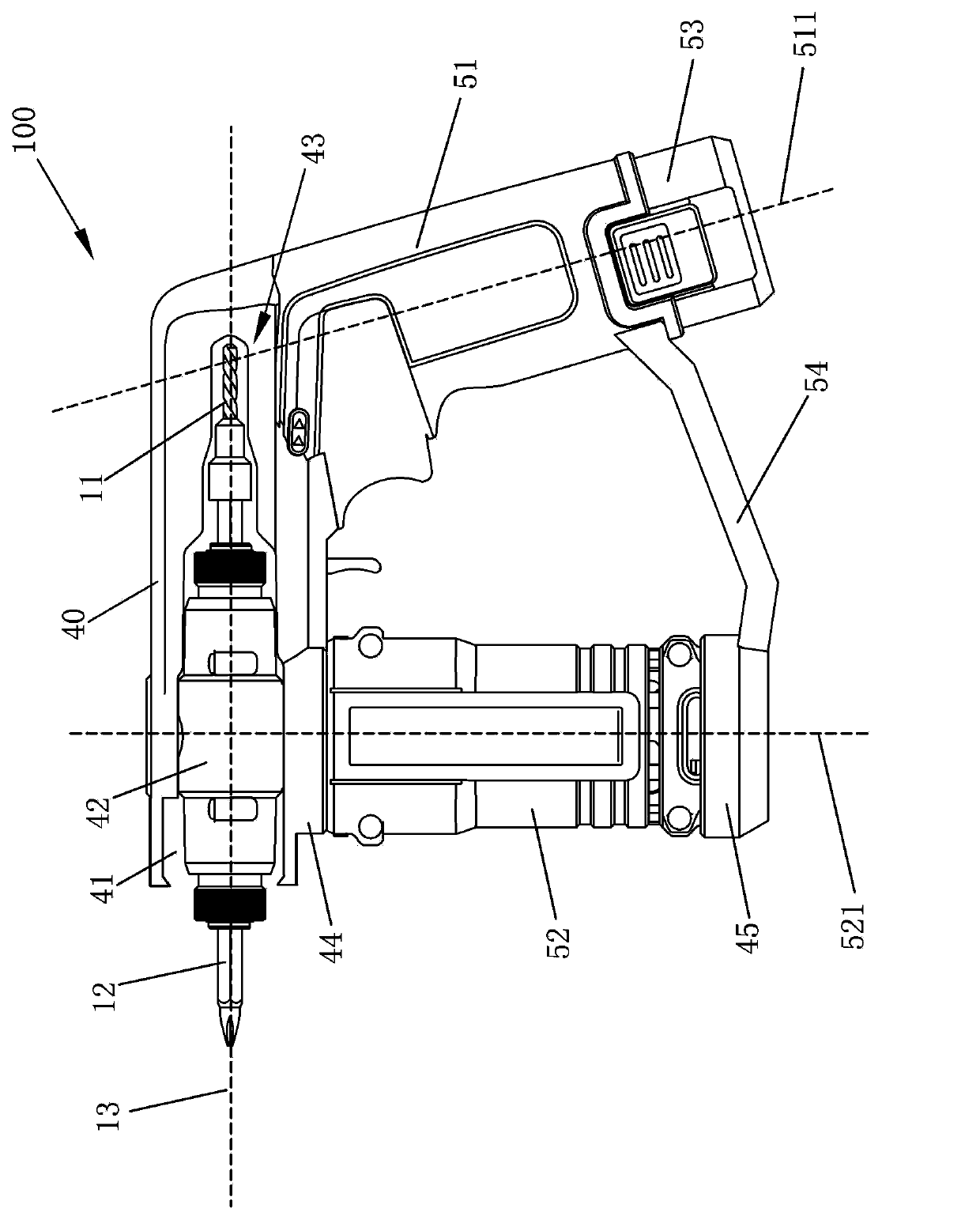

[0031] The electric tool 100 provided by the present invention has at least two working heads of different types. By adjusting the position of each working head, the currently required working head is kept at the processing end of the electric tool 100 facing the workpiece to be processed, so that the electric tool 100 has a variety of processing capabilities.

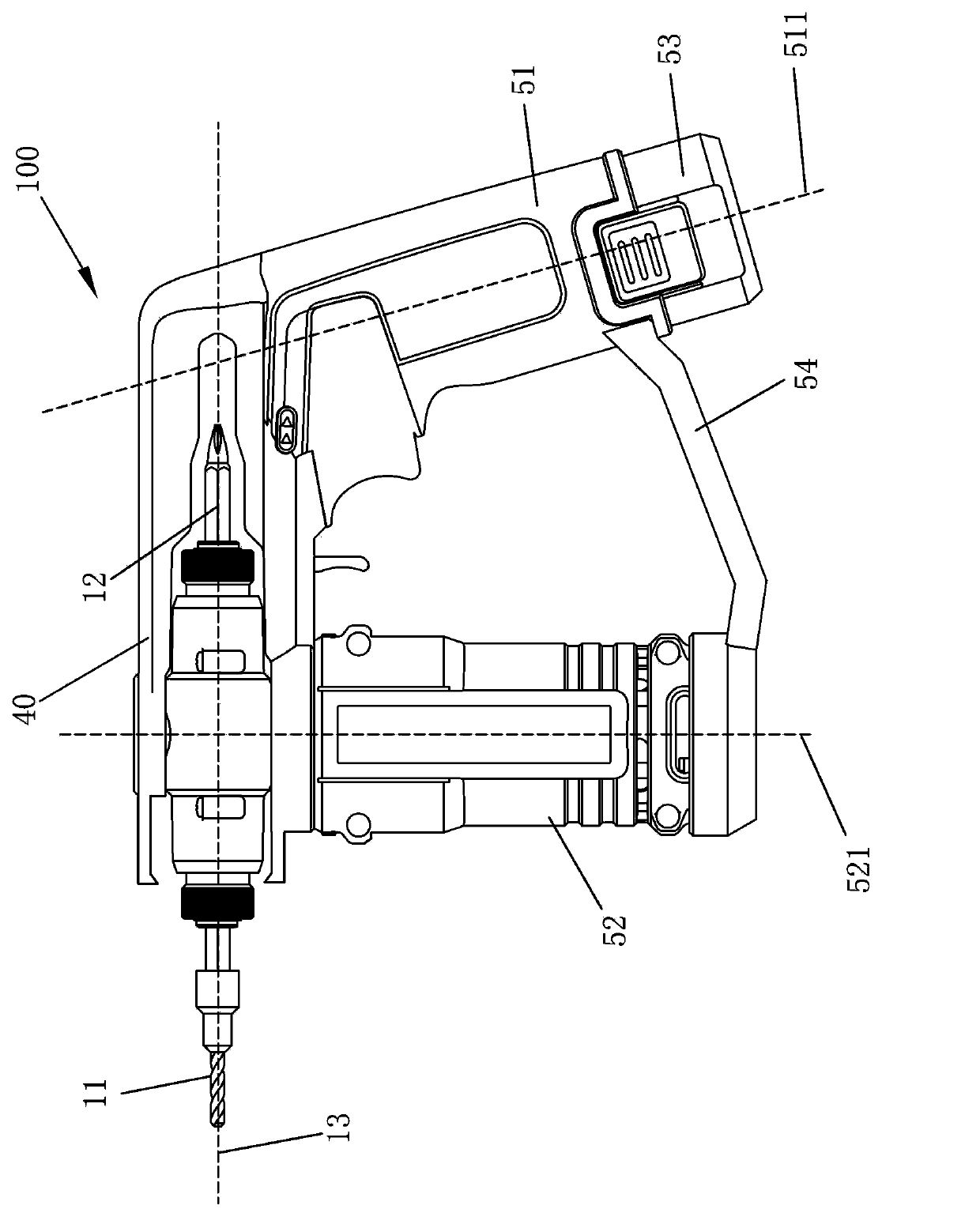

[0032] ginseng figure 1 , figure 2 and image 3 As shown, in an embodiment of the present invention, the electric tool 100 includes first and second working heads 11 and 12, preferably, the two working heads are respectively a bit and a dri...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap