Carton binding machine

A technology of binding machine and carton, applied in the field of carton binding machine, can solve the problems of narrow support arm, low work efficiency, laborious operation of workers, etc. of the binding machine, and achieve the effect of fast binding speed and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

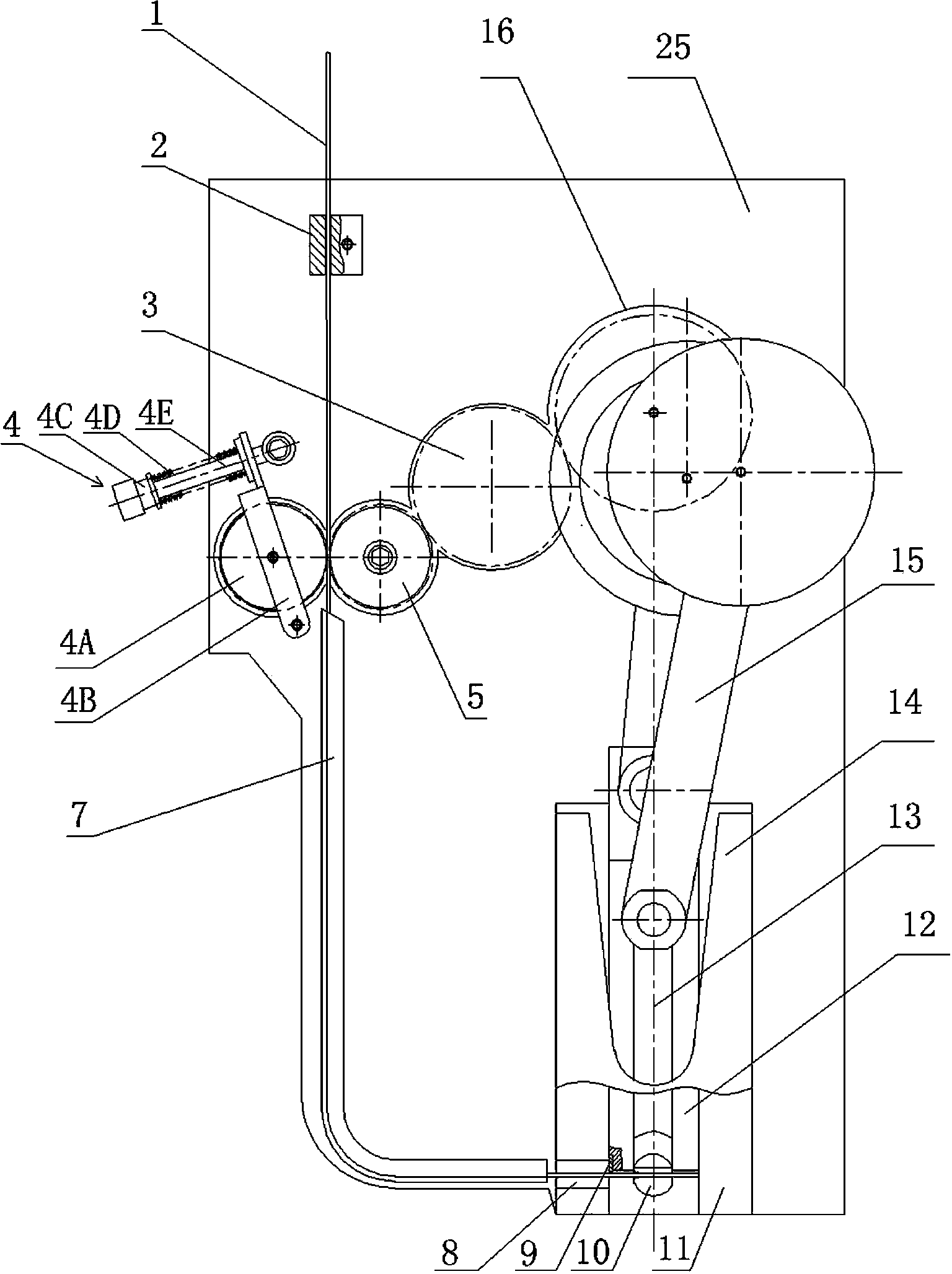

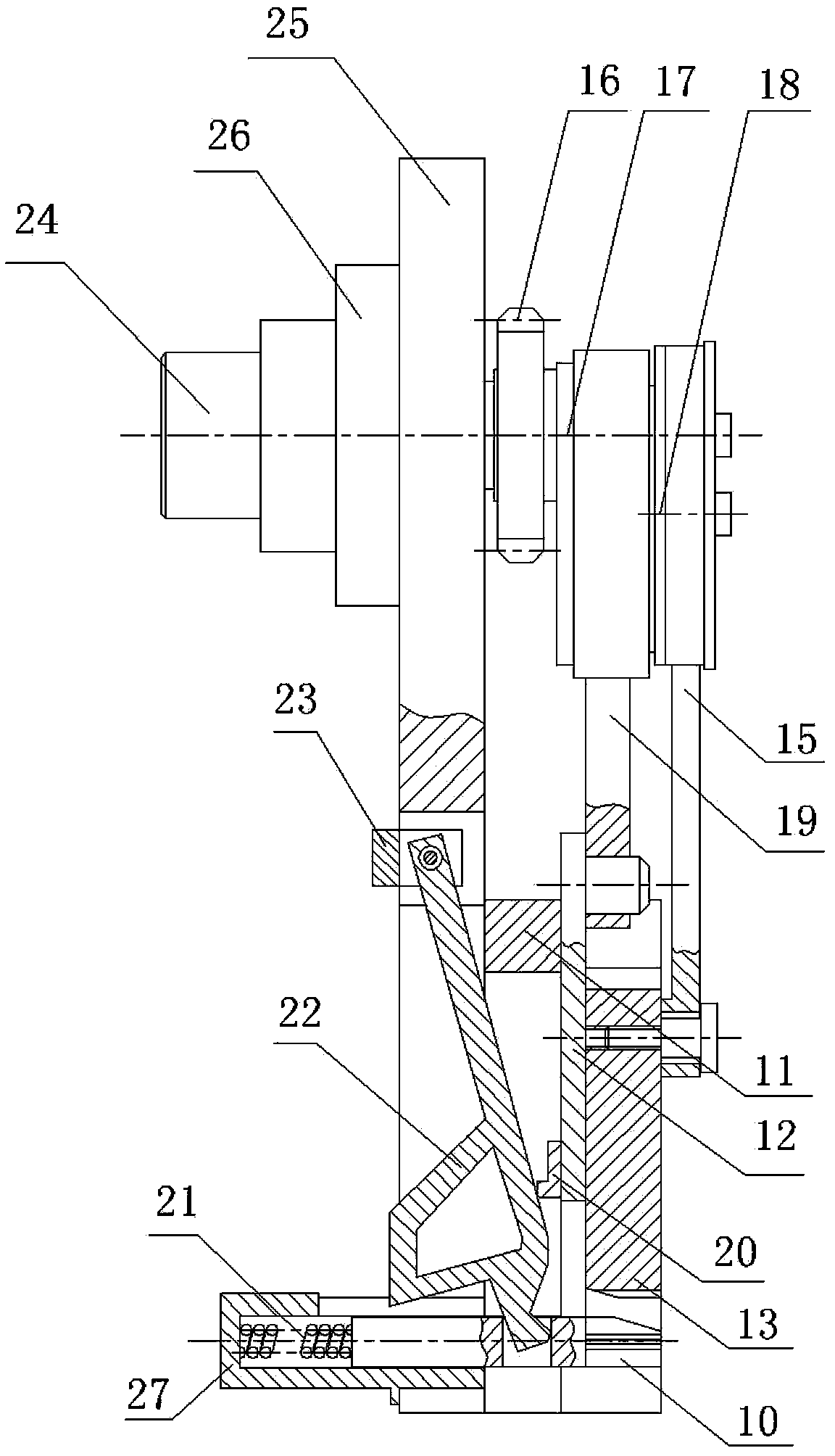

[0023] Such as figure 1 and figure 2 As shown, a carton binding machine provided by the present invention is composed of the following components:

[0024] 1. Frame and spindle assembly

[0025] Such as figure 1 and figure 2 As shown, the frame and main shaft assembly includes a frame 25, and the frame 25 is provided with a main shaft hole, a spring plate groove, a sleeve hole, a springboard groove and several threaded holes. The frame 25 is connected with a bearing seat 26 , and the bearing seat 26 is connected with a main shaft 24 .

[0026] 2. Wire feeding components

[0027] Such as figure 1 As shown, the wire feeding assembly consists of a wire feeding slider 2, a wire feeding wheel 5, and a wire pressing device 4

[0028] , 7 components of wire guide rails.

[0029] The wire feeding slider 2 is connected with the frame 25, and the wire feeding slider 2 is provided with a square through hole.

[0030] The wire feed roller 5 is connected with the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com