Screen printing machine allowing substrate to be located conveniently

A technology for screen printing machines and substrates, applied in screen printing machines, printing machines, rotary printing machines, etc., can solve problems such as the inability to meet the multi-color printing of products and the inability to fix the left and right positions of the substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

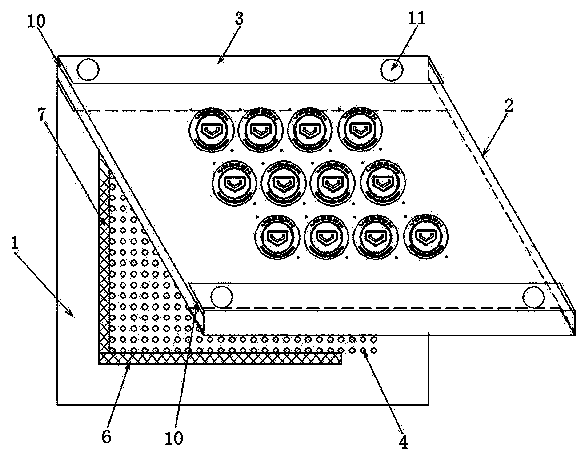

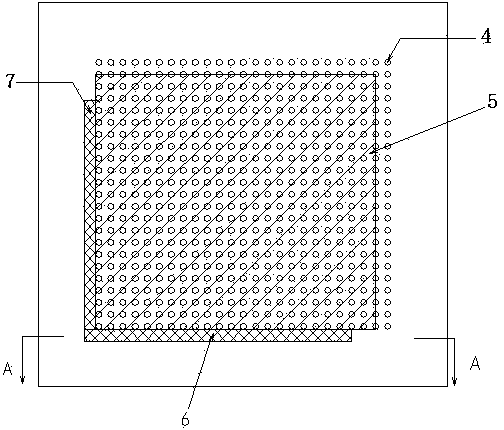

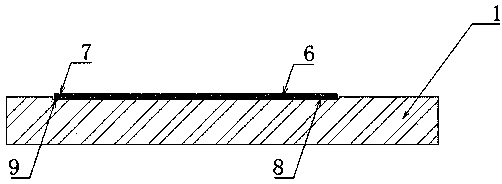

[0017] Embodiments of the present invention are described below with reference to the accompanying drawings so that those skilled in the art to which the present invention pertains can easily implement the present invention.

[0018] See figure 1 , a kind of screen printing machine that this embodiment provides to facilitate the positioning of substrates includes a printing table 1, a suction fan, and a screen device slot 3 for loading a screen printing plate 2, and the printing table 1 has a plurality of Regularly distributed sieve holes 4, through which the suction fan sucks the air between the substrate 5 placed on the printing table 1 and the printing table 1, so that the pressure difference between the upper and lower sides of the substrate 5 is generated, thereby fixing the substrate The up and down position of object 5. The screen device slot 3 is connected to one end of the printing table 1, and the screen printing plate 2 is inserted into the two card slots 10 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com