Printing grey balance presetting method

A technology of gray balance and printing machine, applied in printing, printing machine, printing device and other directions, can solve the problems of inability to guarantee accurate reproduction of gray balance, poor layering of printed matter, etc., to achieve sustainable development and improve printing production efficiency , improve the effect of adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, the present invention will be further described:

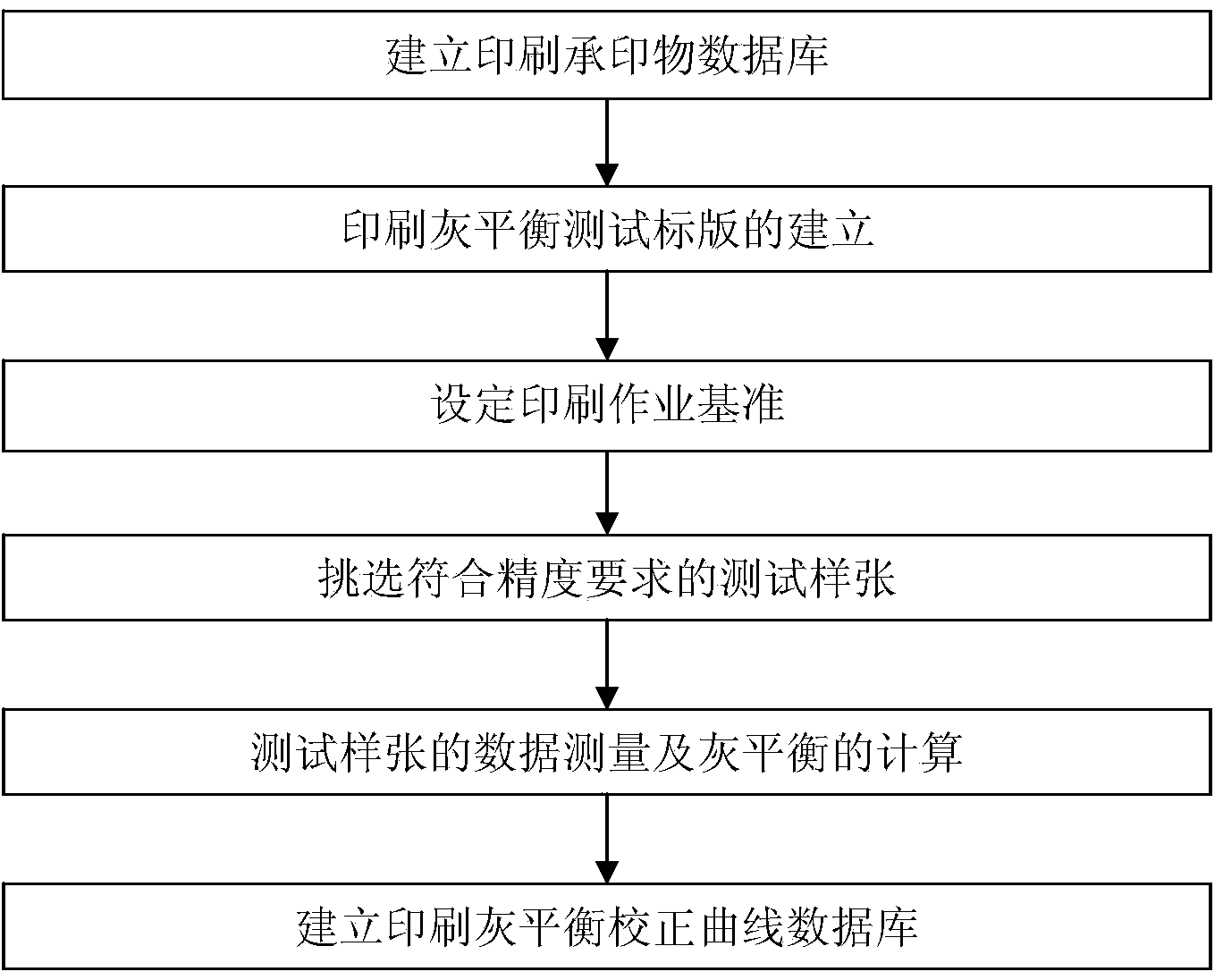

[0039] Such as figure 1 , figure 2 and image 3 As shown, a printing gray balance preset method includes the following steps:

[0040] Step 1. Create a printed substrate database

[0041] According to the substrate brand, substrate type and substrate color used by the printing enterprise, a printing substrate database is established with the substrate name as the only retrieval basis and the substrate brand, substrate type and substrate color as the characteristics.

[0042] Step 2. Create a printing gray balance test target

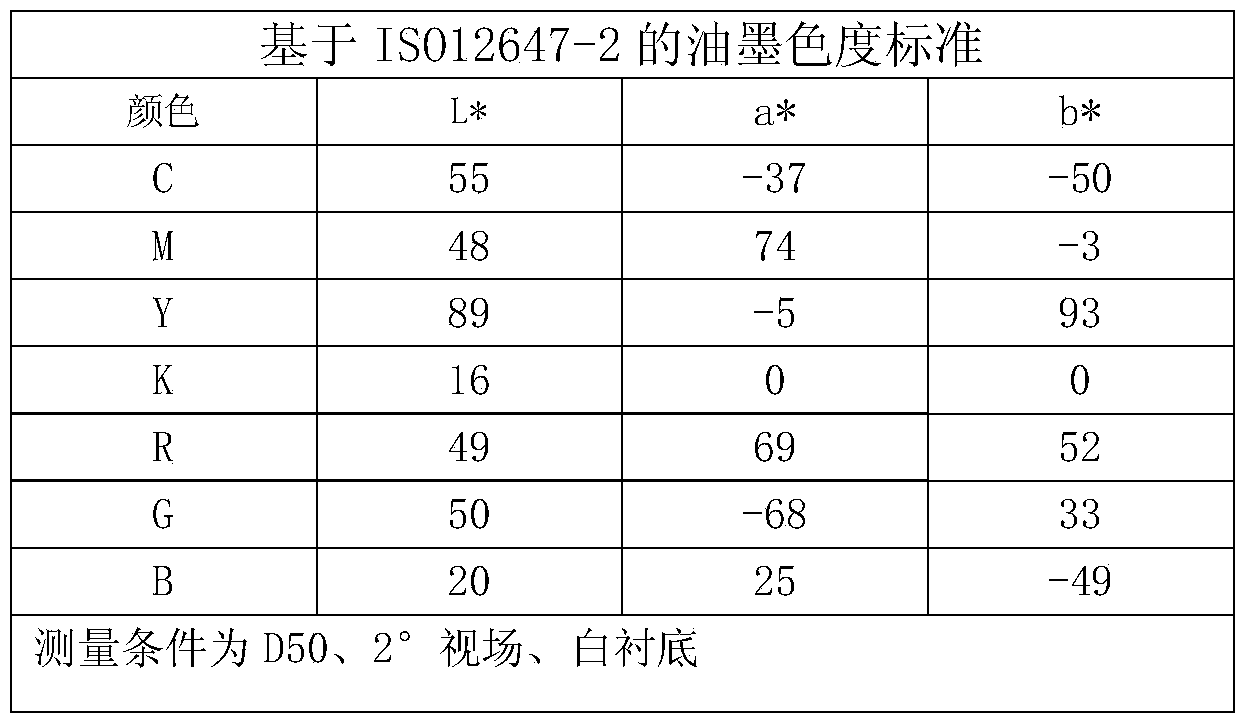

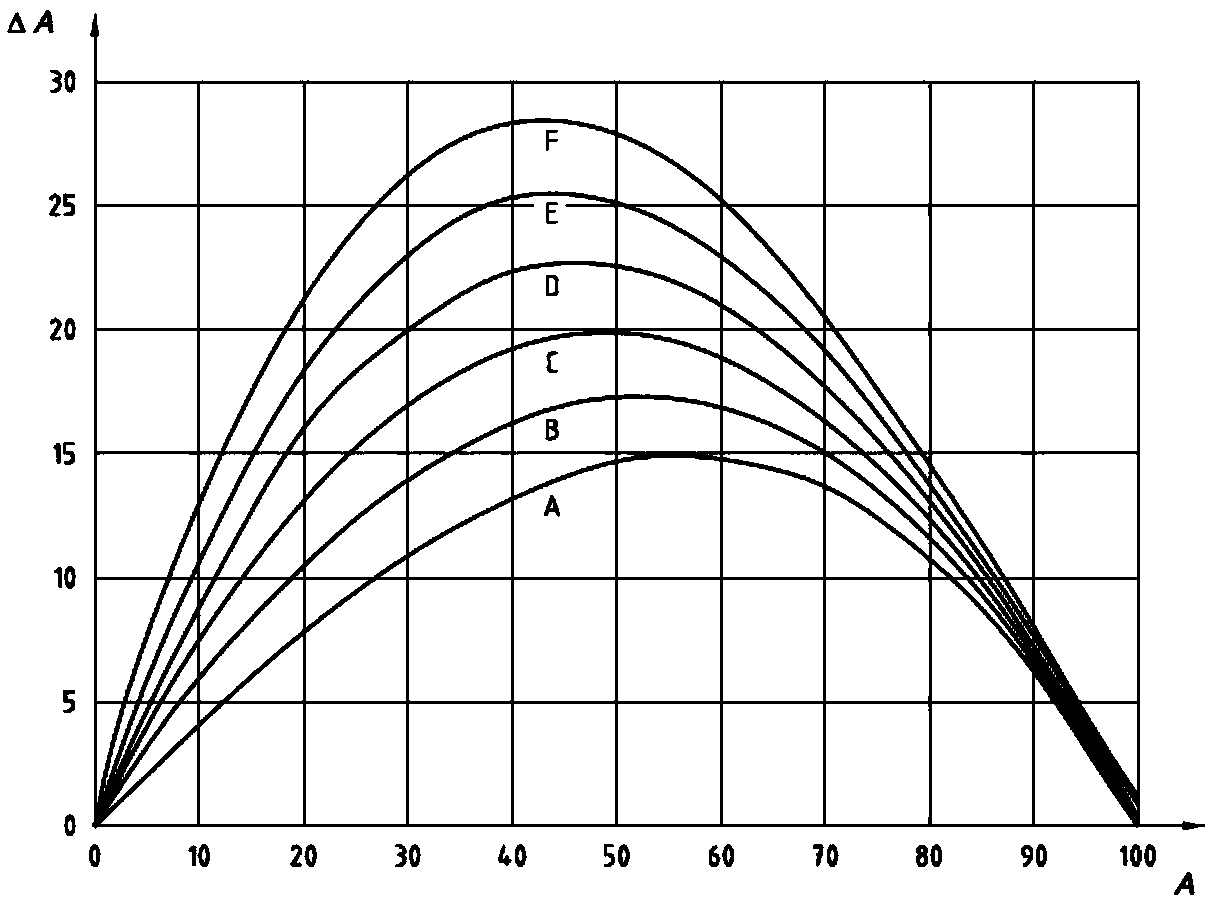

[0043] According to the type of general-purpose computer-to-plate equipment CTP and the type of printing machine in the printing enterprise, design the printing gray balance test standard plate. The printing test standard contains the following elements: gray balance correction module, IT8.7 / 4 color target, CMYKGRB dot scale, gray balance gradi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com