Battery mounting bracket for automobile

A technology for installing brackets and batteries, which is applied to battery pack components, circuits, electrical components, etc., can solve the problems of many components, complex structure, and long battery assembly operation time in the production process, and achieves reduced man-hours, simple structure, and convenient installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention are described in detail below in conjunction with accompanying drawing:

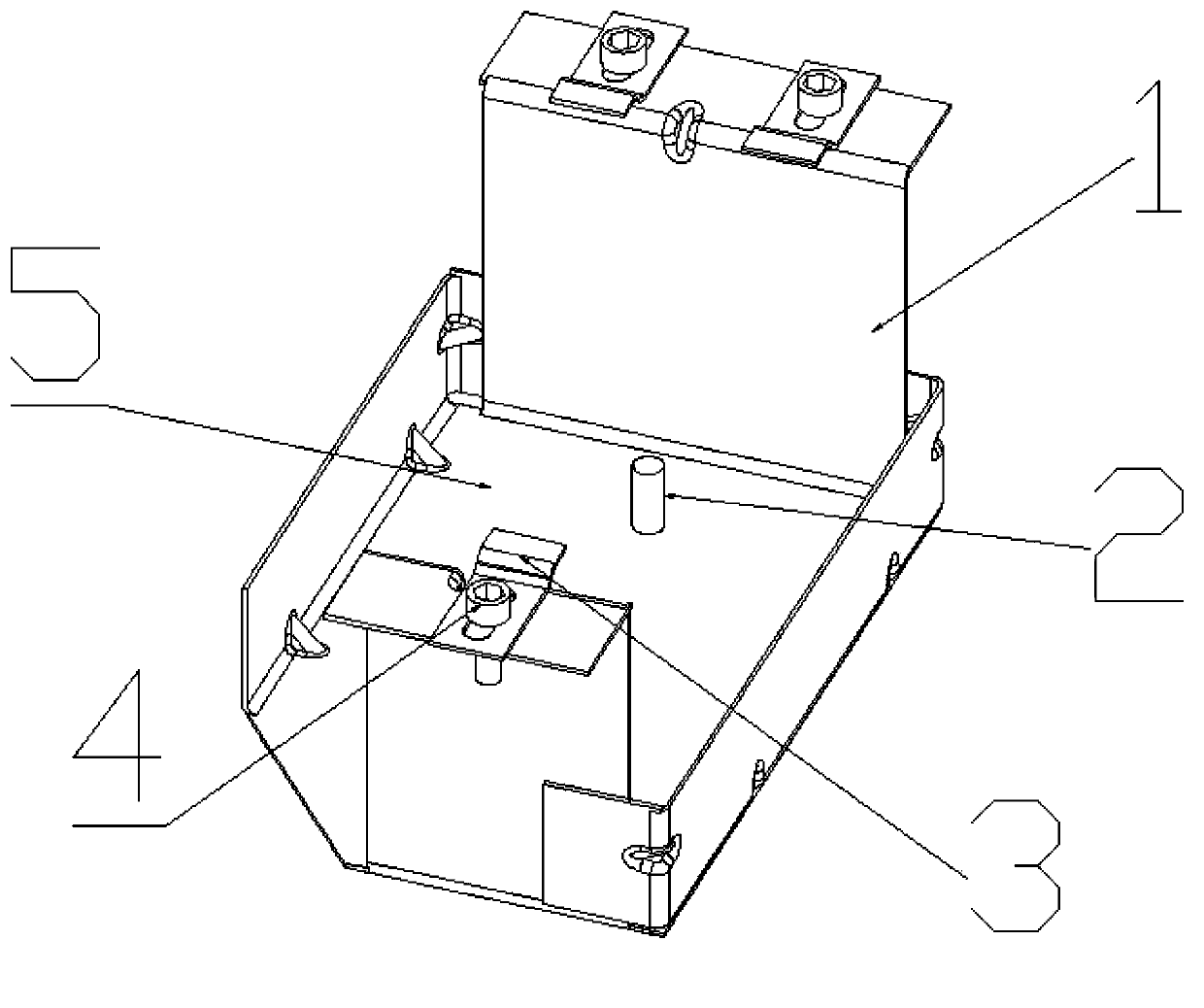

[0013] Such as figure 1 As shown, a battery mounting bracket for automobiles includes a bracket body. The bracket body includes a semi-closed box 5 matching the shape of the battery. The top of the box 5 is open. Locating pin 2, baffle plate 1 is provided at the box bottom edge of box body 5, and baffle plate 1 is welded on box bottom edge, and baffle plate 1 upper edge is provided with sliding fastening block 3, and sliding fastening block 3 is fastened by fastening Screw 4 is fixed on the upper edge of baffle plate 1. The sliding fastening block 3 can slide on the edge of the baffle plate 1, thereby ensuring better fixing of the storage battery.

[0014] In this embodiment, the bottom of the box is square and one corner is cut off, and baffles 1 are provided at the two relatively parallel short sides of the bottom of the box.

[0015] In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com