All-terrain telescopic-leg-type fix-foot rotating advancing robot

A robot and telescopic leg technology, applied in the field of all-terrain telescopic leg hexapod rotating forward robot, can solve the problems of small grounding specific pressure, difficult to move smoothly, and large degree of damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

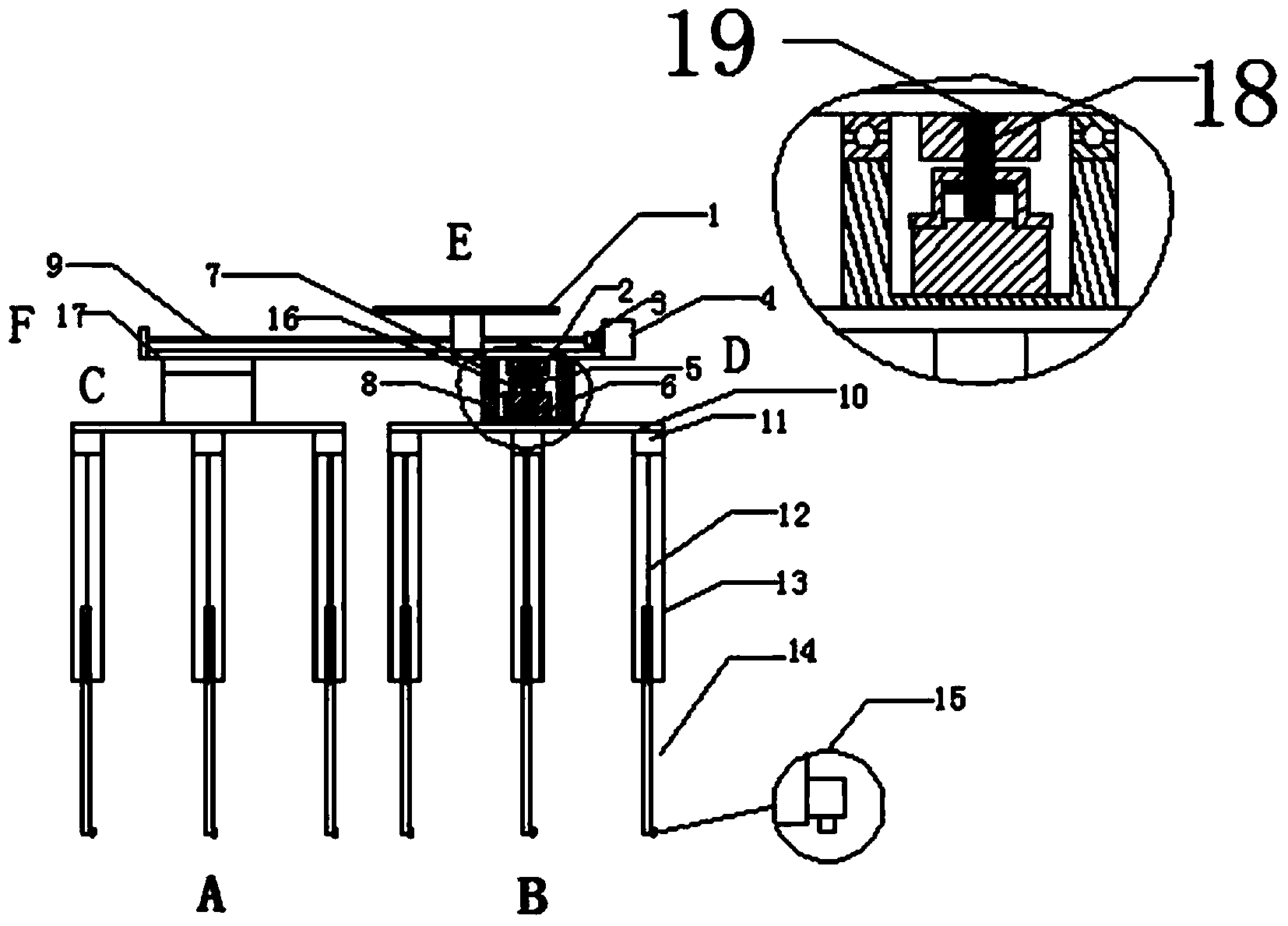

[0008] Embodiment: the motor (4) is connected with the leading screw 9 through a coupling (3). Guide rail (17) is that the upper and lower planes are rectangular planes, the right part can fix the motor (4), and the left end has a flat plate to fix the guide rail (17). The platform (1) is connected with the leading screw (9), and the bottom surface of the platform (1) is in contact with the top surface of the guide rail (17), so that the platform (1) can linearly reciprocate on the guide rail (17). The guide rail 17 is in contact with the upper part of the plane thrust bearing 7 . The center of the straight-line carrying platform (2) is a regular hexahedron hole, and a large cylindrical low hole is arranged on the top. The linear guide rail carrying platform (2) is bonded and fixedly connected with the guide rail (17). The connecting shaft (5) is a helix as a whole, and the top is a hexahedron with a threaded hole in the center, a raised cylinder in the middle, a cylinder in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com