A kind of line friction U-shaped belt conveyor

A belt conveyor, U-shaped technology, used in conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as low conveying efficiency, huge energy consumption, environmental pollution, etc., to improve utilization efficiency and ensure normal operation. , the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

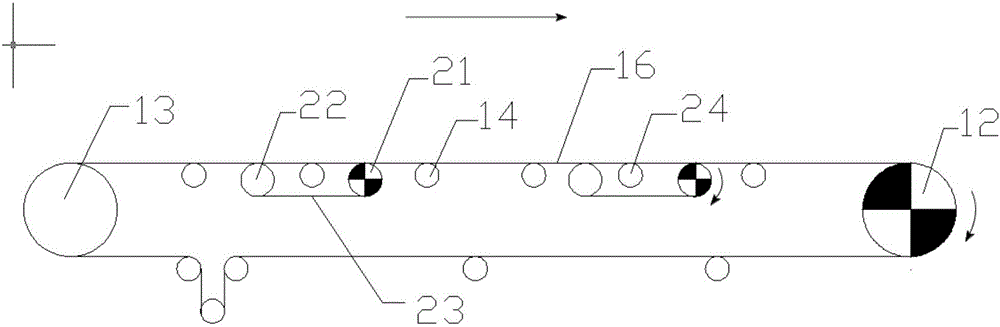

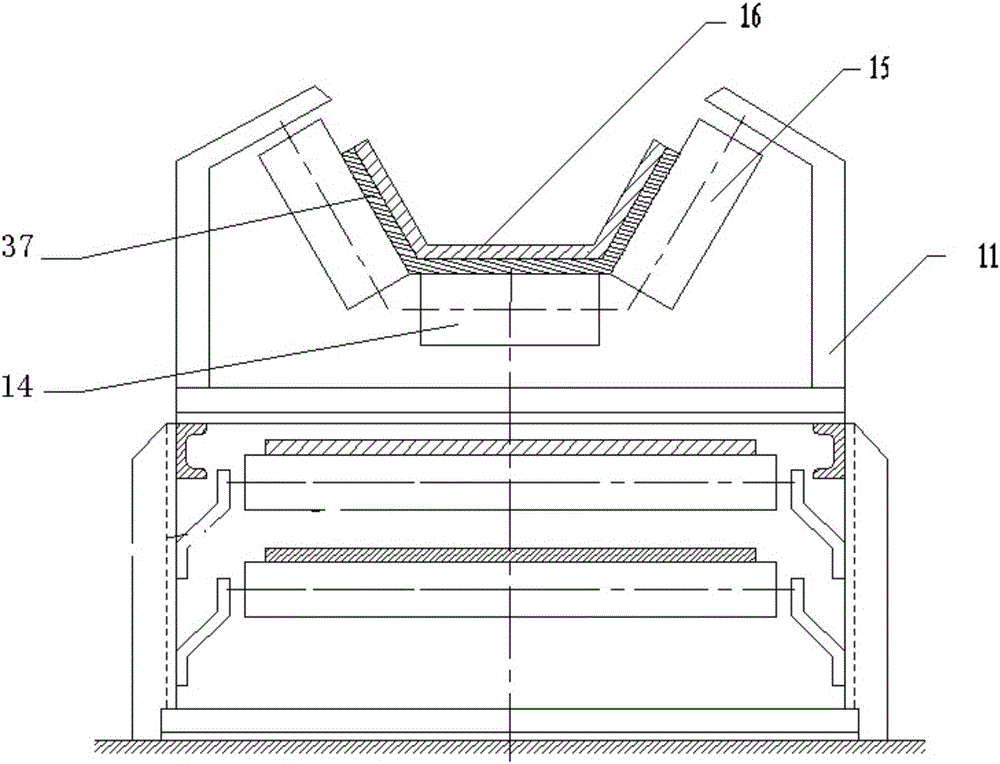

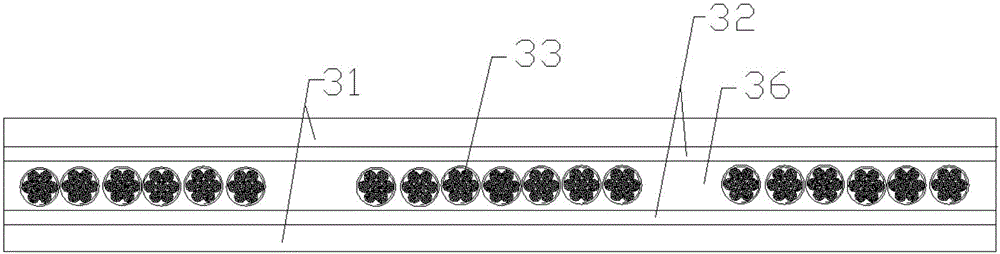

Embodiment 1

[0023] Such as Figure 1 to Figure 4 As shown, the present invention includes a main engine and at least one auxiliary force-applying device installed on the main engine. The main engine includes a bracket, and is installed on the bracket: the head roller 12 positioned at the end of the bracket, the tail roller positioned at the other end of the bracket 13. Loading idler 14, edge idler 15, drive belt 16 connecting the head roller 12 and tail roller 13 and located on the surface of the load idler 14 and edge idler 15, the head roller 12 is externally connected with a power device The auxiliary booster device is located between the drive belts 16, including: secondary traction rollers 21, secondary driven rollers 22, booster rollers 24, connecting secondary traction rollers 21 and secondary driven rollers 22 installed on the main frame , the booster belt 23 located on the booster roller 24 and in contact with the drive belt 16, the auxiliary traction roller 21 is externally conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com