A kind of phase-transfer catalytic interfacial polycondensation method preparation and separation and purification method of polyarylate

A purification method and polyarylate technology are applied in the field of preparation of copolyarylate resin to achieve the effects of low consumption, simplified process and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

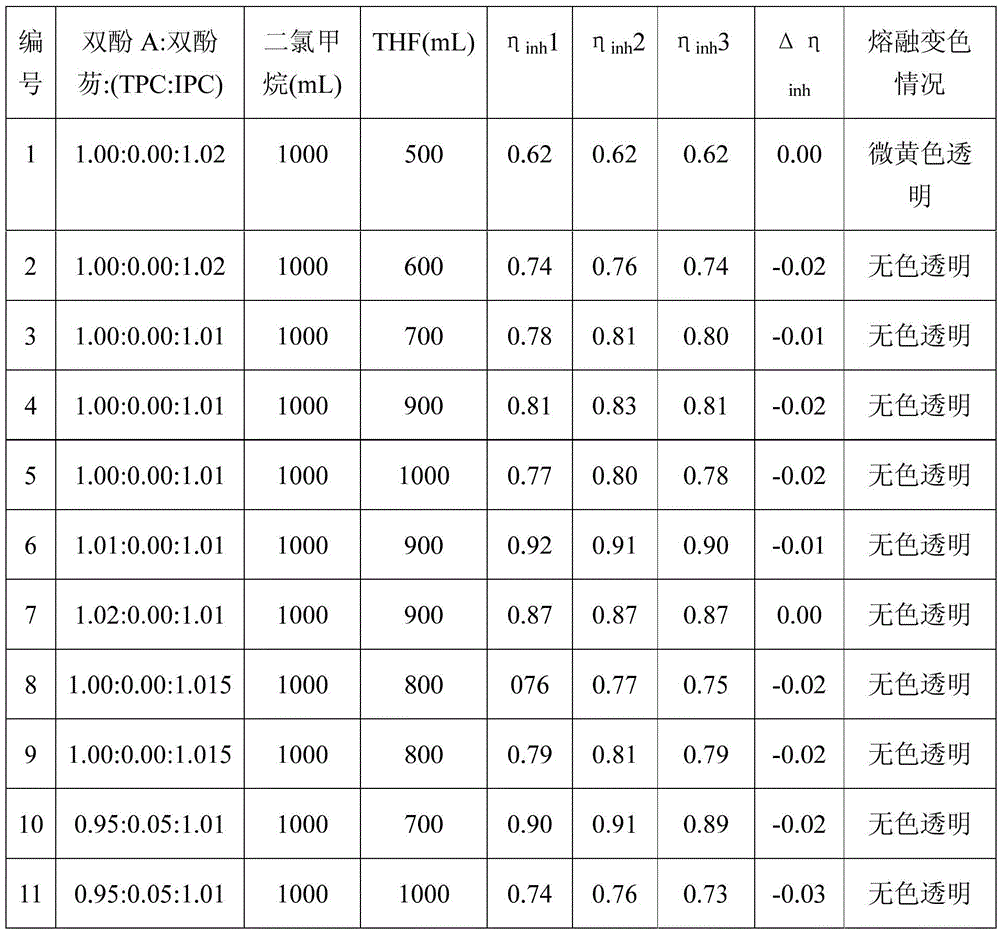

Examples

Embodiment 1

[0034] The typical preparation process of PAR resin refining solution is as follows:

[0035] Add 500 mL of deionized water, 0.3 g of sodium bisulfite, and 26.4 g (0.66 mol) of sodium hydroxide into a clean 3000 mL three-necked flask equipped with an electric stirrer. 68.4g (0.30mol) of bisphenol A, stir to completely dissolve bisphenol A to form a water-soluble sodium salt, add 0.50-1.0g of benzyltriethylamine chloride, stir and cool to below 10°C.

[0036] Dissolve 18.64g (0.0918mol) of TPC and 43.48g (0.2142mol) of IPC in 1000mL of dichloroethane to form an organic phase. Slowly add the organic phase to the above-prepared aqueous phase under rapid stirring, and complete the addition in about 30 minutes. Then add 50 mL of aqueous solution containing 1.18 g (0.0126 mol) of phenol and 0.53 g (0.013 mol) of NaOH, continue stirring for about 4 hours, neutralize the excess NaOH in the reaction liquid with formic acid, and make the pH value of the reaction mixture to 3-5 , static...

Embodiment 2

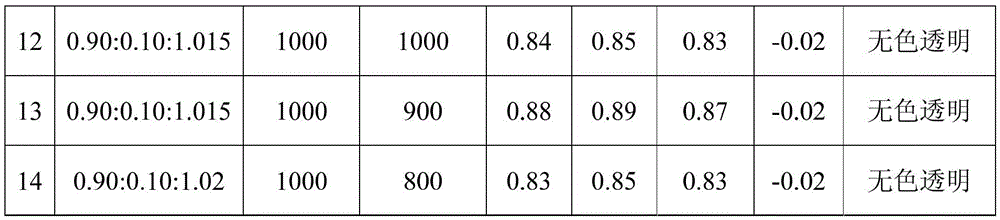

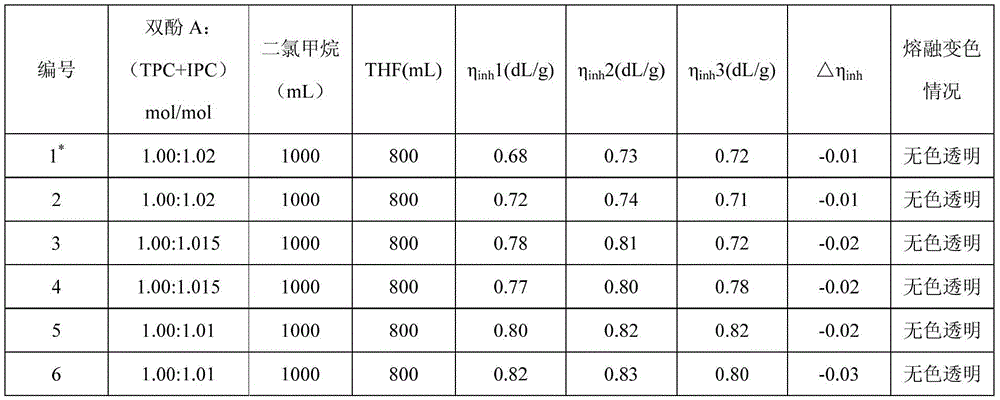

[0045] With the reclaimed methylene chloride (37 ℃~41 ℃ fraction), prepare PAR resin according to the same operation procedure of embodiment 1, experimental result is listed in table 2.

[0046] Table 2 reclaims dichloromethane to PAR resin η inh Impact

[0047]

[0048] *Dichloromethane and THF are the experimental data of the first use of industrial products; 2~6 are the data of recovery of dichloromethane and THF. Example 3

Embodiment 3

[0049] Use 1,2-ethylene dichloride instead as the organic phase solvent, and DMF is as the separating agent, and according to the method of embodiment 1, the η of PAR resin inh 1 is 0.67dL / g, and the DMF separating agent is evaporated to obtain white granular resin, η inh 2=0.71dL / g, after heating and melting at 300℃±10℃ for 5min, the resin is colorless and transparent, η inh 3 is 0.68dL / g, Δη inh =-0.03dL / g, the resin yield was 94.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com