Rotational flow shoe

A swirl shoe and swirl channel technology, applied in drilling equipment, drilling equipment and methods, earthwork drilling and other directions, can solve the problem of low pressure bearing capacity, easy to damage the suspended state of the floating shoe string, and it is difficult to ensure that the pipe string is centered and other problems to achieve the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

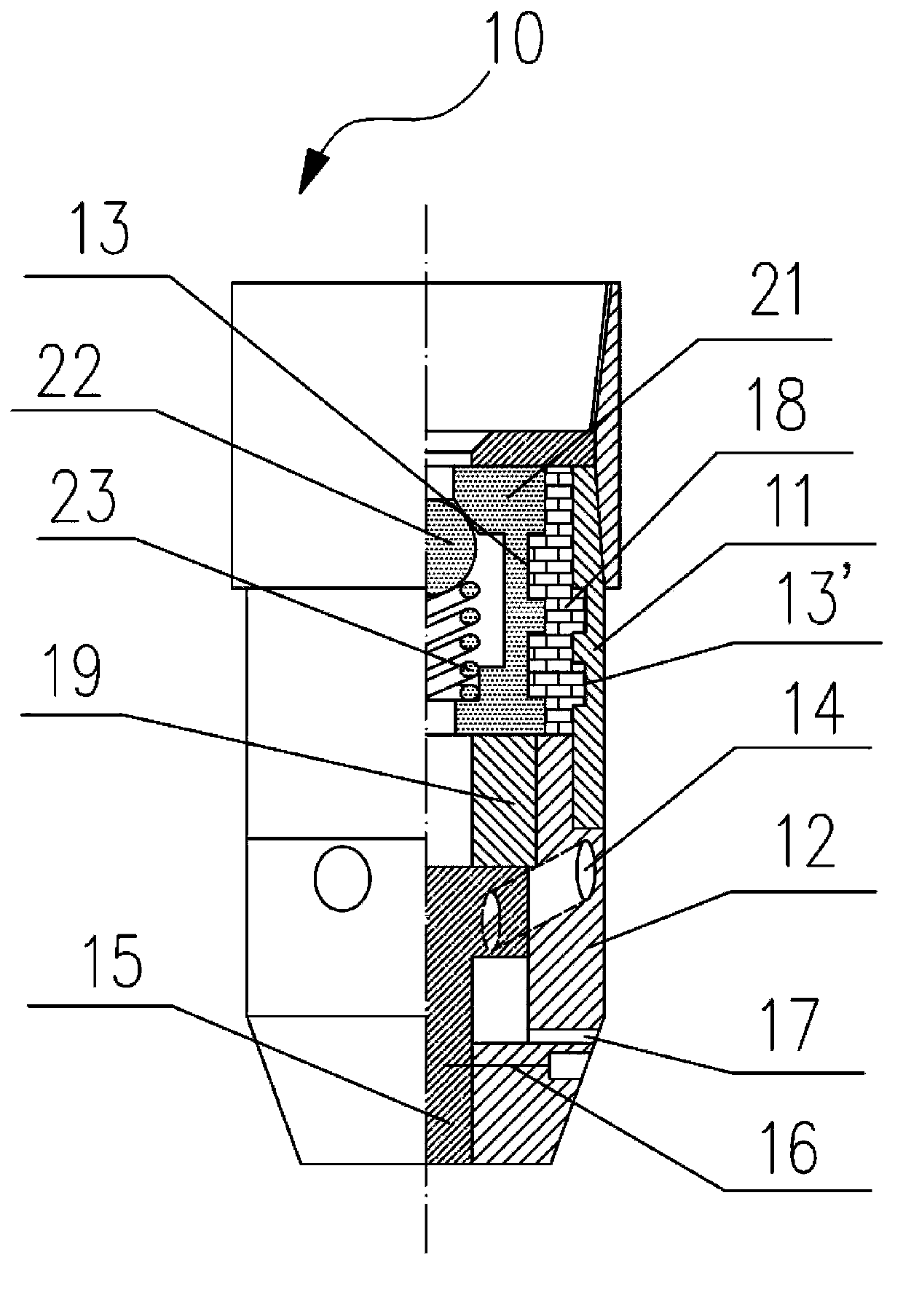

[0017] The present invention will be further described below in conjunction with accompanying drawing.

[0018] figure 1 The internal structure of the swirl shoe 10 according to the present invention is schematically shown. The swirl shoe 10 includes a casing 11, and a connecting pipe 12 is installed at the downstream end of the casing 11. Both the casing 11 and the connecting pipe 12 are hollow structures to form a fluid channel. In one embodiment, the connecting pipe 12 is also provided with a swirl channel 14 penetrating through the side wall of the connecting pipe 12, so as to establish circulation inside and outside the casing (not shown). In a preferred embodiment, the connecting pipe 12 is detachably connected to the downstream end of the casing 11, so that the assembly of the swirl shoe 10 is more convenient. In one embodiment, the connecting pipe 12 is screwed to the housing 11 .

[0019] The swirl shoe 10 also includes a differential pressure valve fixed inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com