Vacuum pressure regulating valve

A vacuum pressure and regulating valve technology, applied in valve details, safety valve, balance valve, etc., can solve the problems of complex structure and increased cost, and achieve the effects of reliable experimental performance, convenient pressure setting and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

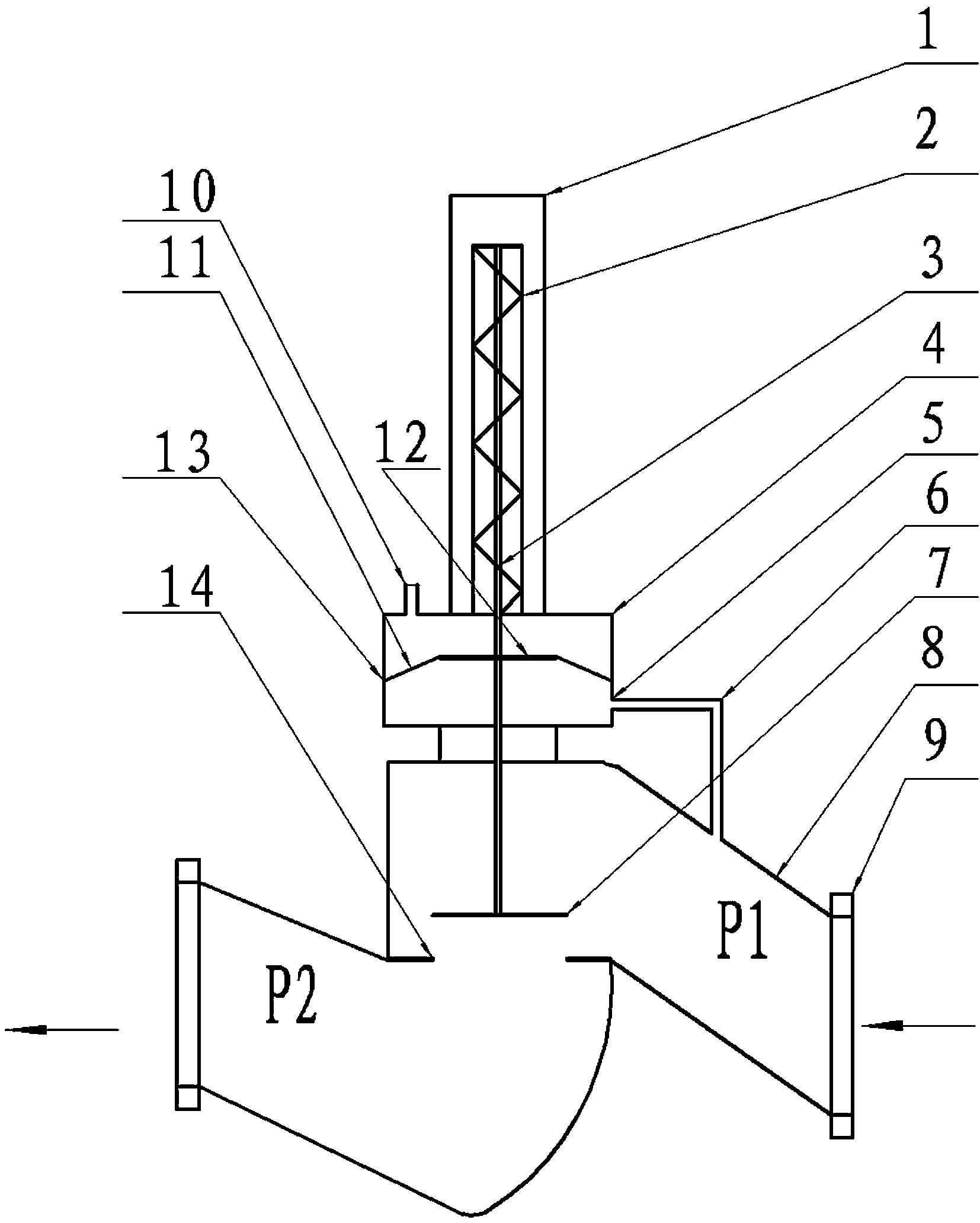

[0011] A vacuum pressure regulating valve includes a vacuum valve body 8 , a valve stem 3 , a valve core 7 , a spring 2 and an actuator 13 . The valve body 8 is welded to both ends of the valve body 8 through two DN250 flanges 9 connecting the pipelines at both ends of the vacuum control valve, so that the valve and the pipeline are integrated. Valve hole 14 for flow. The actuator 13 is fixed to the valve body 8 . The actuator 13 is composed of an upper casing 4 , a lower casing 5 , a tray 12 , a diaphragm 11 , a vent hole 10 and a pressure guide tube 6 . The diaphragm 11 is sandwiched between the assembled upper case 4 and the lower case 5, so that the upper case 4 and the lower case 5 are sealed by the diaphragm 11, and the tray 12 is arranged in the lower case 5, The air vent 10 is arranged on the upper casing 4 and communicates with the atmosphere, so that the air pressure of the upper casing is consistent with the atmospheric pressure. One end of the pressure guiding tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com