Combustion chamber

A combustion chamber and fuel technology, applied in the field of machinery, can solve problems such as insufficient combustion of fuel, and achieve the effect of reducing the generation of harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

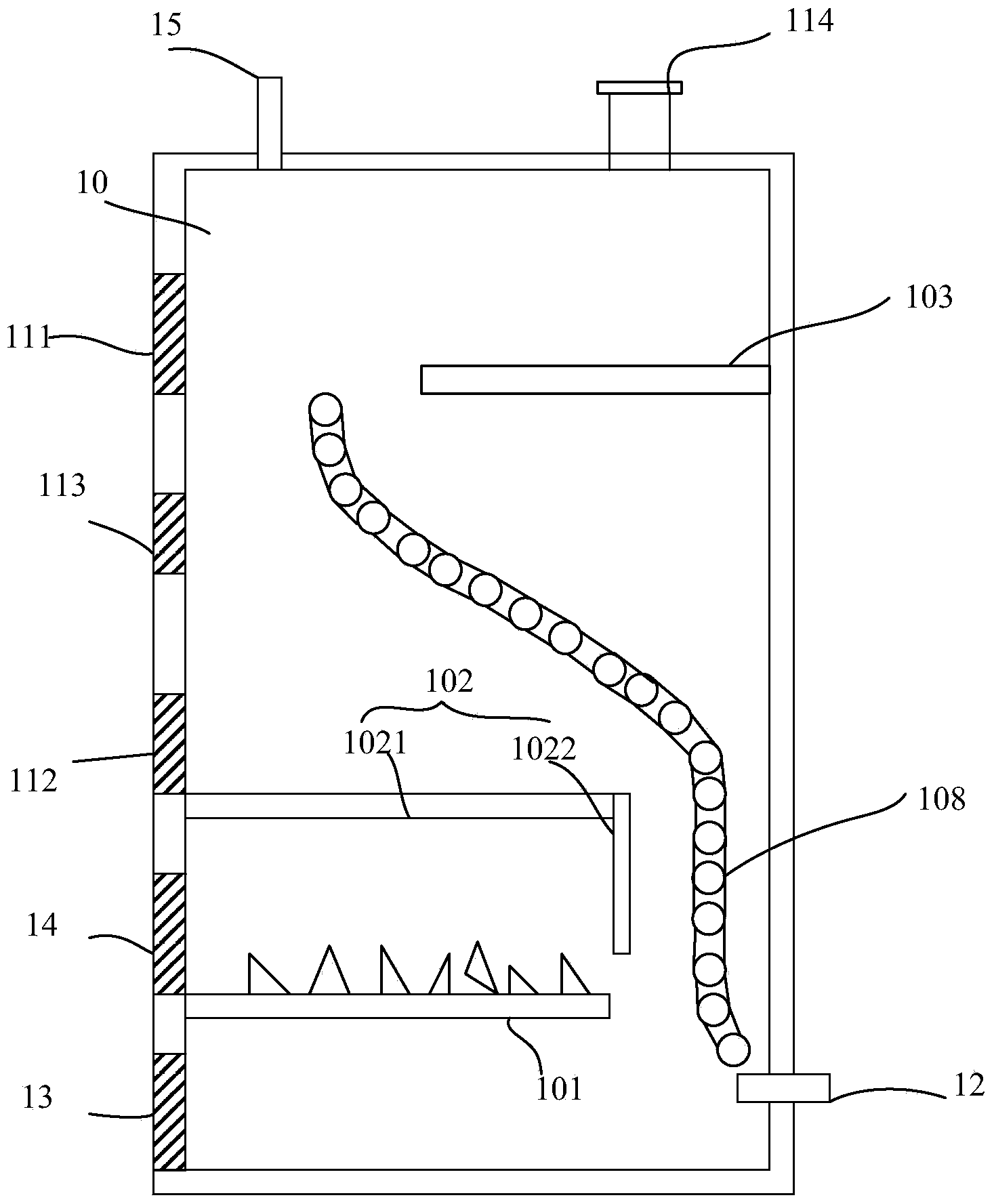

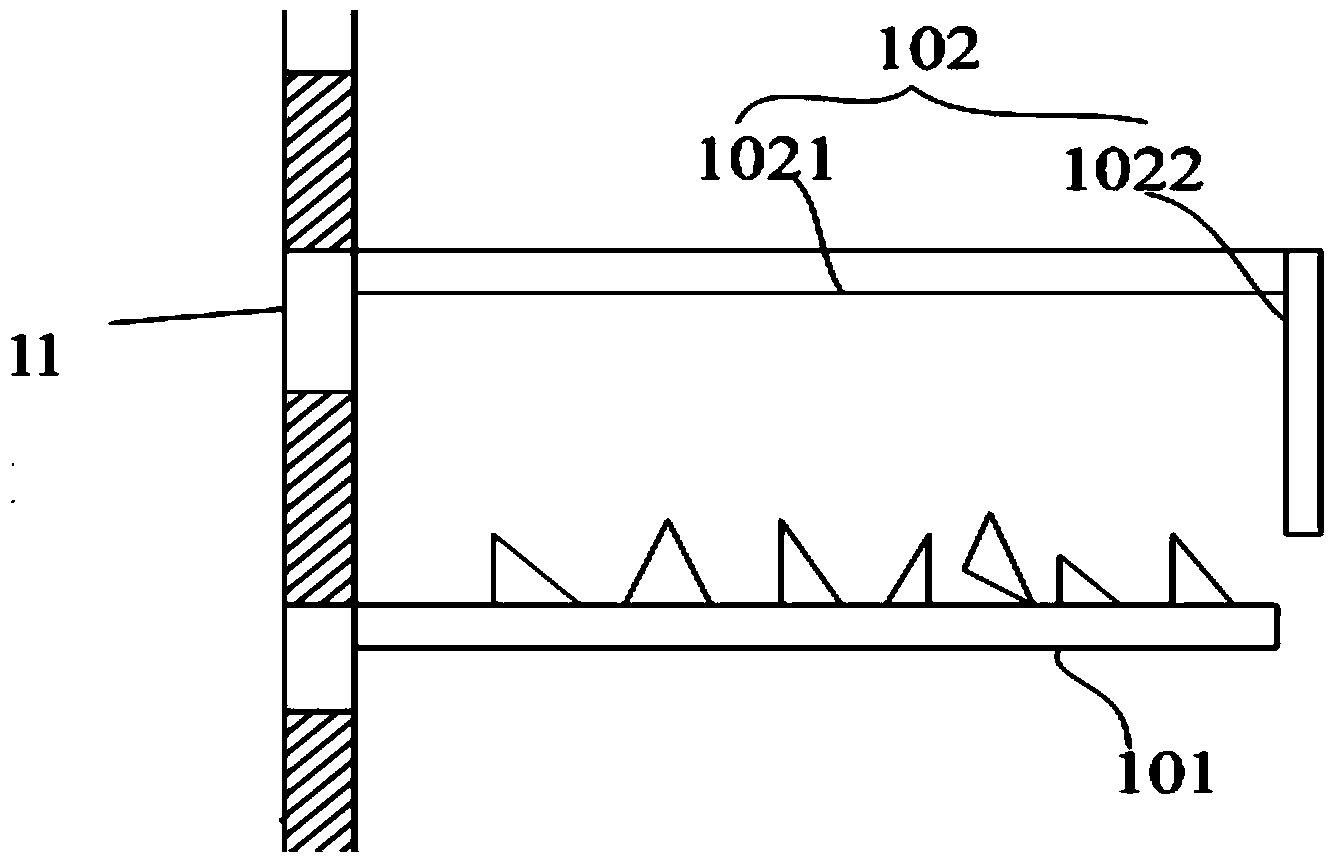

[0029] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

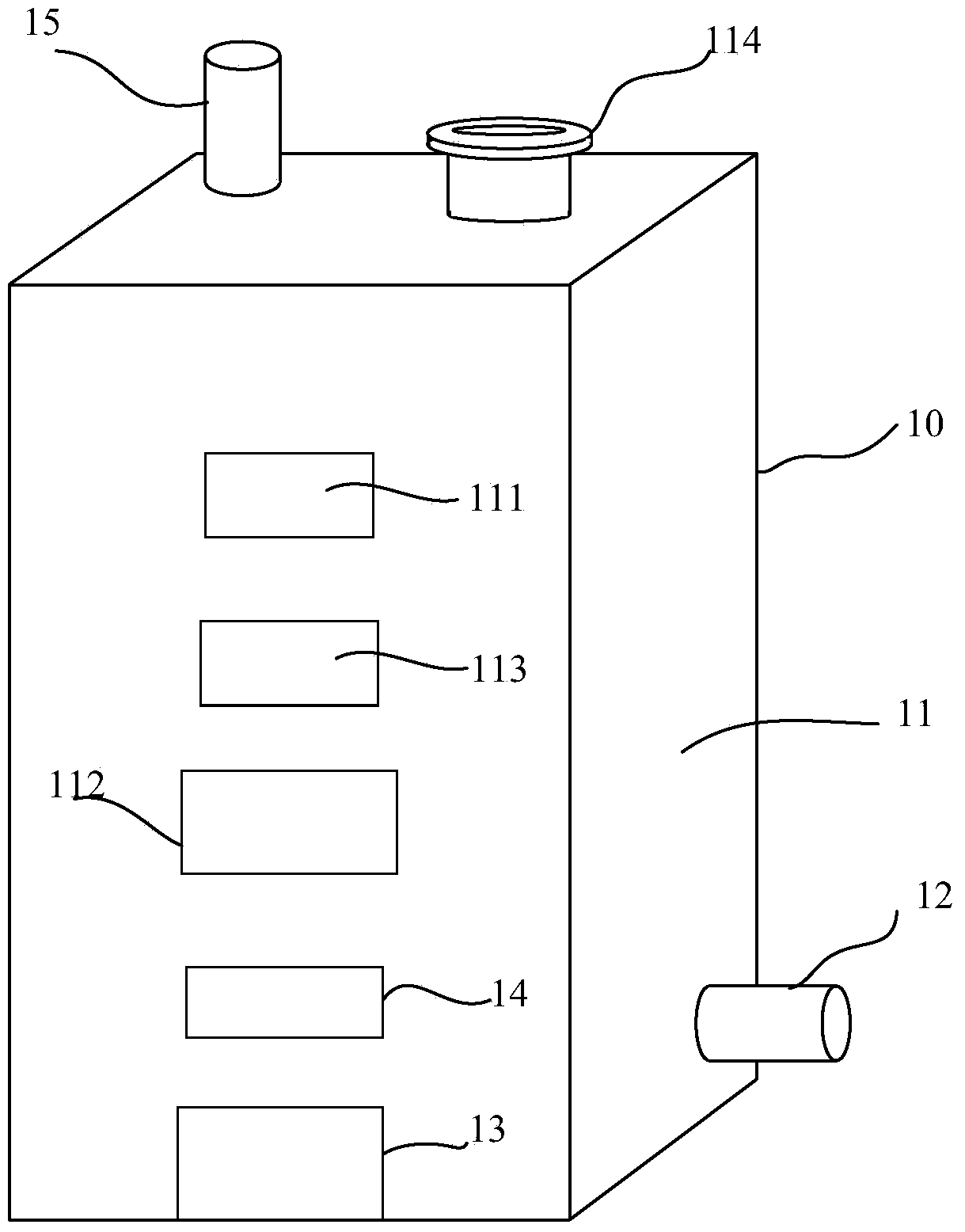

[0030] figure 1 It is an application scene of the combustion chamber provided by the present invention, that is, a schematic structural diagram of a combustion furnace including the combustion chamber. Depend on figure 1 It can be seen that the burner includes a furnace body 10 surrounded by a furnace wall 11, and a water pipe (not shown) is arranged inside the furnace body 10, and the water pipe connects / communicates with the water outlet 15 on the top of the burner and the Describe the water inlet 12 at the bottom of the burner. The furnace body 10 is in the shape of a cabinet as an example, but it is not limited thereto. The furnace body can also be in the shape of a barrel or other shapes, which is not limited.

[0031] The furnace wall 11 can be a solid structure or a hollow structure. If it is a hollow struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com