Lean burn engine

An engine, lean-burn technology, used in combustion engines, internal combustion piston engines, machines/engines, etc., can solve the problems of insufficient rigidity, high design and manufacturing requirements, and unsatisfactory manufacturing accuracy, and achieves the reduction of harmful gases. The effect of producing, airtightness and practicability is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

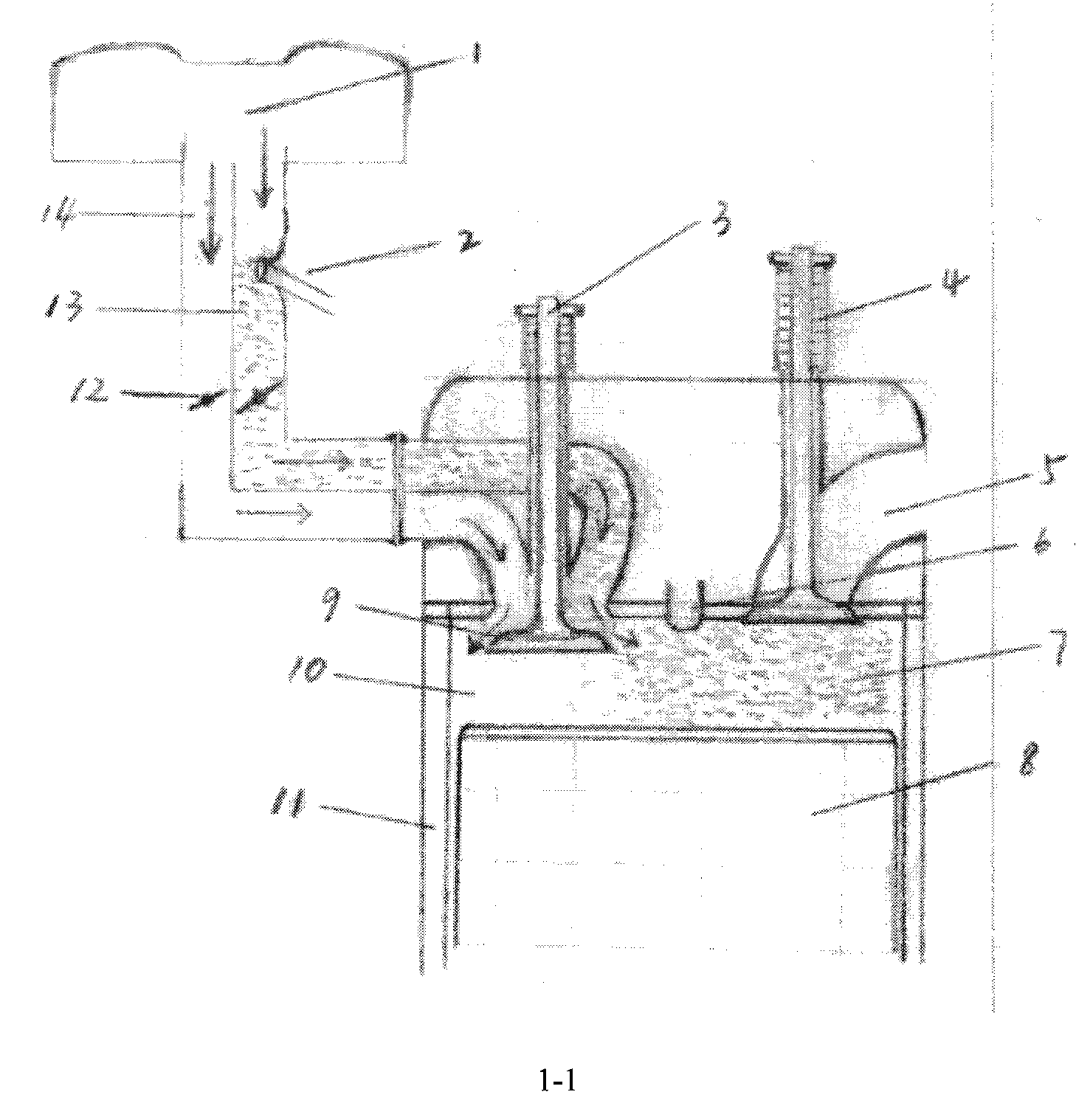

[0023] exist Picture 1-1 Middle: The intake port (1) divides the air entering the cylinder. When the air passing through the intake passage (13) passes through the fuel injection pipe (2), it mixes with the injected fuel to form a fuel mixture flow, which flows from near the spark plug One side enters the cylinder; in addition, the air passing through the intake passage (14) is not mixed with the fuel, and forms a convection flow with the fuel mixture flow in the cylinder, and the suction force generated by the piston movement guides the flow direction of the airflow. Respective backflows are formed, and the fuel mixture gas flow gathers around the spark plug (6), which is easy to ignite and burn, thereby ensuring that the fuel mixture gas can be ignited and burned in a short time; the flow rate of gas entering the cylinder can be adjusted and changed through the throttle valve (12) The ratio of air and mixed gas in the cylinder maximizes the air-fuel ratio of the gas in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com