Adjusting mechanism and laser collimator with same

A technology of adjusting mechanism and laser collimation, which is applied in the field of laser collimating instrument and leveling mechanism of laser collimating instrument, can solve the problems of difficulty in taking into account the subdivision precision and speed of the transmission part of the adjustment structure, and achieve the effect of precise control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Various features of the present invention will be described in detail below in conjunction with specific embodiments and drawings.

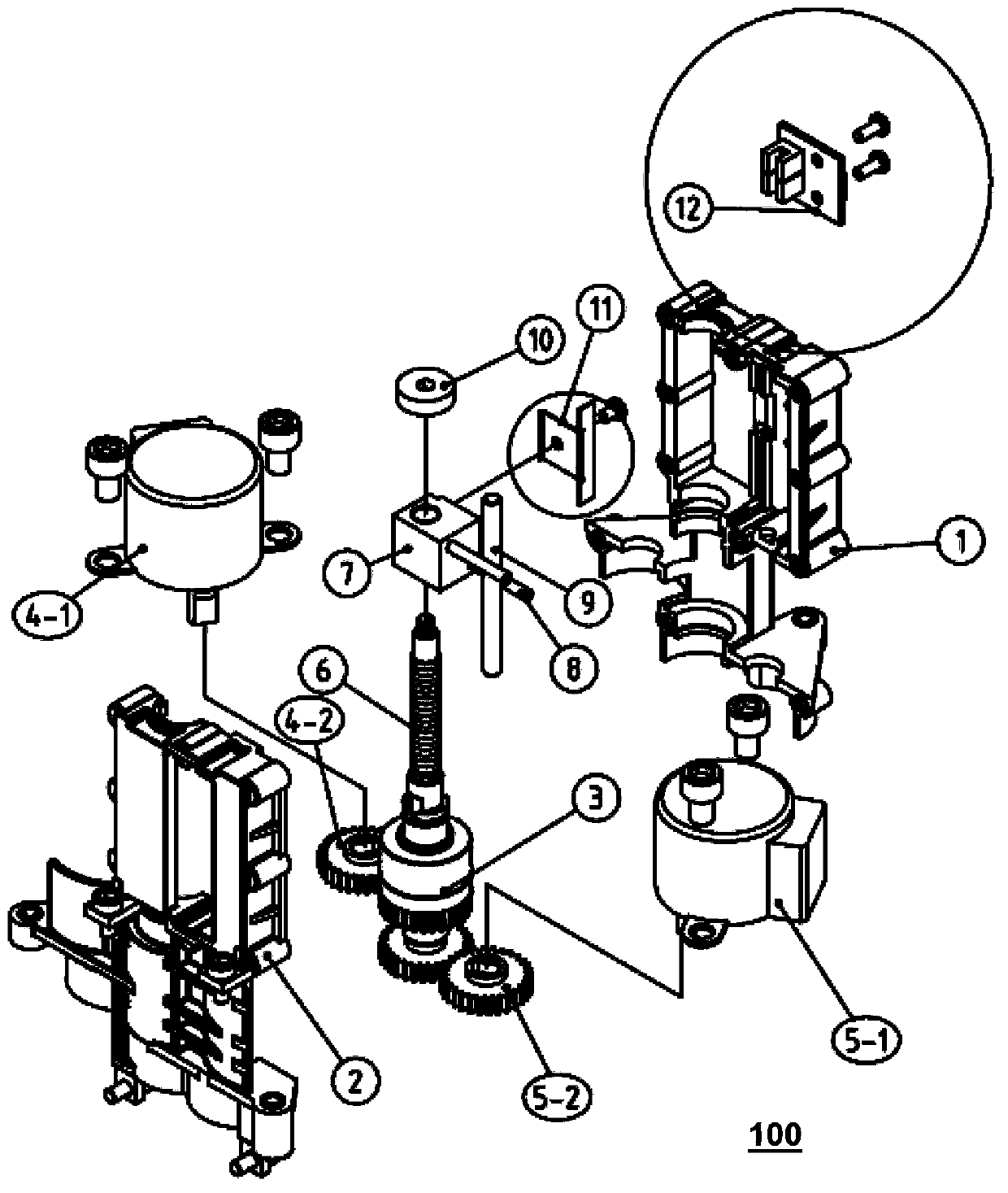

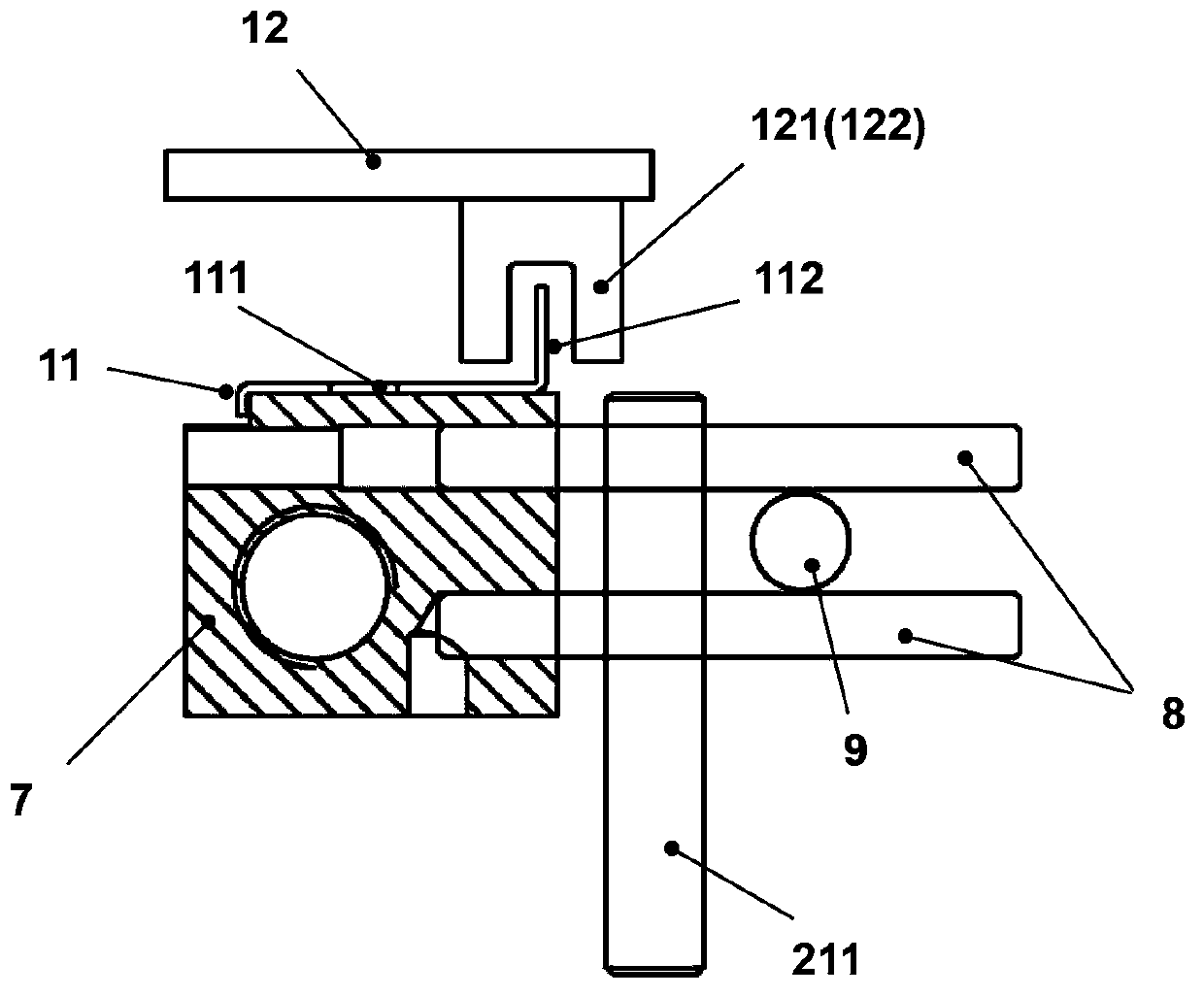

[0027] Please see first figure 1 and figure 2 , figure 1 An adjustment mechanism 100 of a preferred embodiment of the present invention is shown. The adjustment mechanism 100 has a first housing 1 and a second housing 2, and the two housings are combined to form a housing, and a differential 3, a first stepping motor 4-1, and a first driving gear are arranged in the housing. 4-2, the second stepping motor 5-1, the second driving gear 5-2, the screw mandrel 6 and the moving block 7.

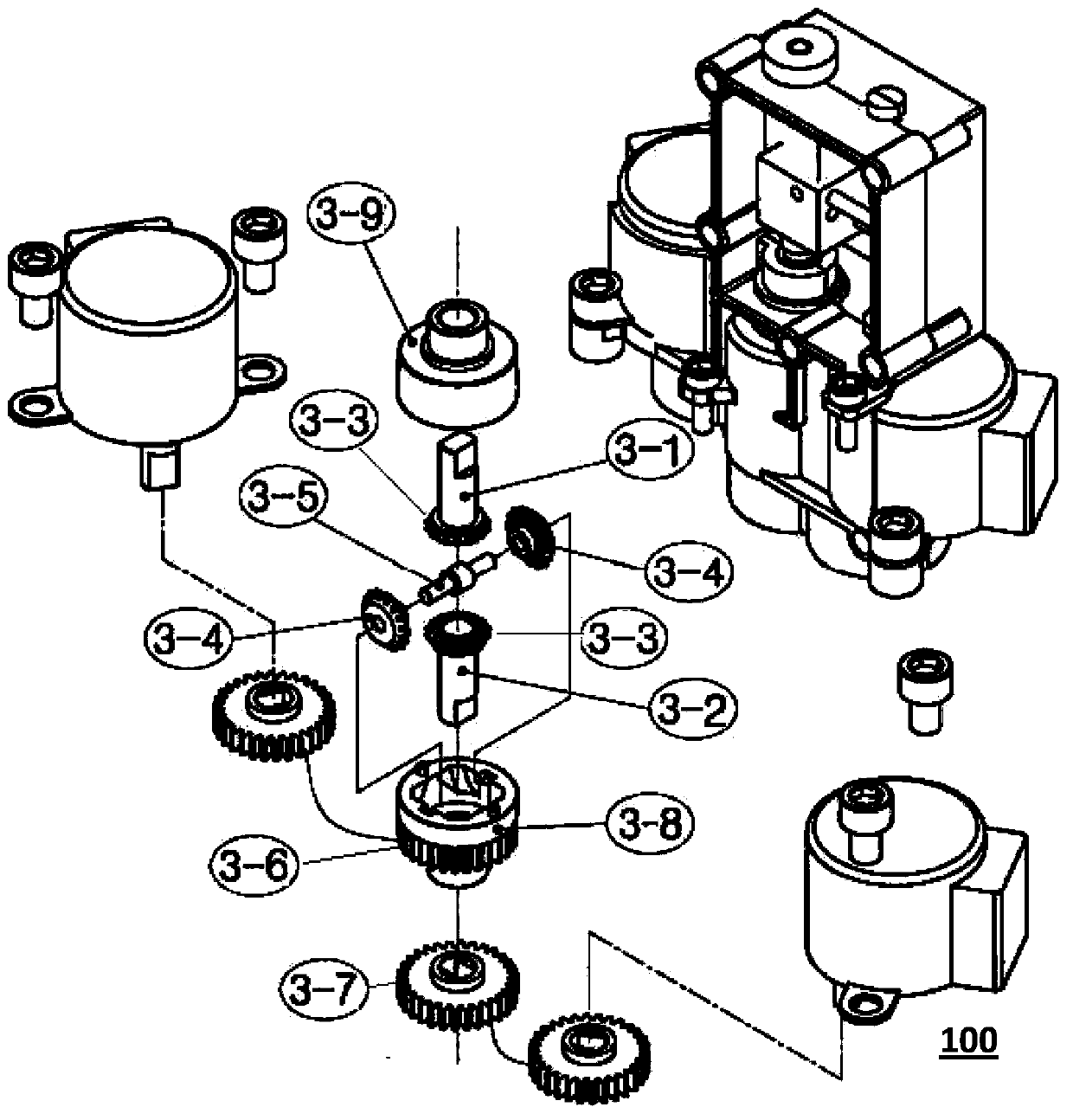

[0028] The differential 3 includes a first output shaft 3-1 and a second output shaft 3-2 having a differential gear 3-3 at one end, and a pair of differential planets connected by a differential planetary gear shaft 3-5. gear 3-4, wherein the planetary gear 3-4 and the differential gear 3-3 mesh with each other. The differential 3 also has an upper casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com