A method for testing the mechanical properties of anti-seismic mild steel

A detection method, mild steel technology, applied in the direction of applying stable tension/pressure to test the strength of materials, preparation of test samples, etc., can solve the problems of different test results, and achieve accuracy, consistency, and reliability operational effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

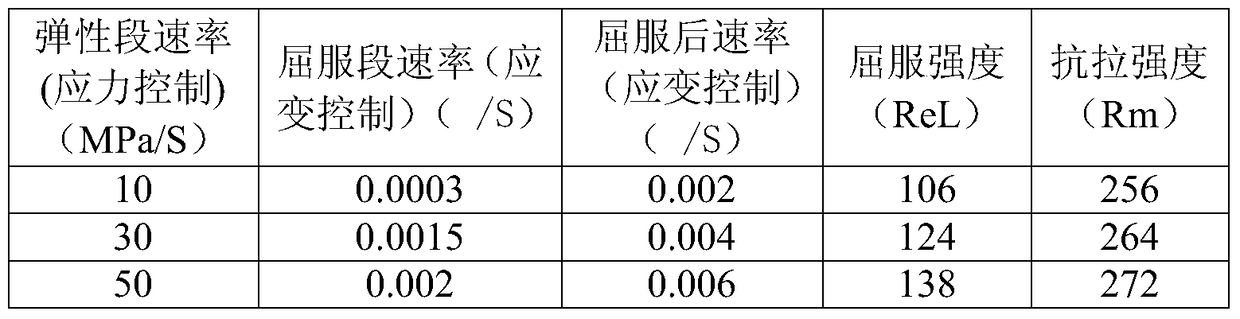

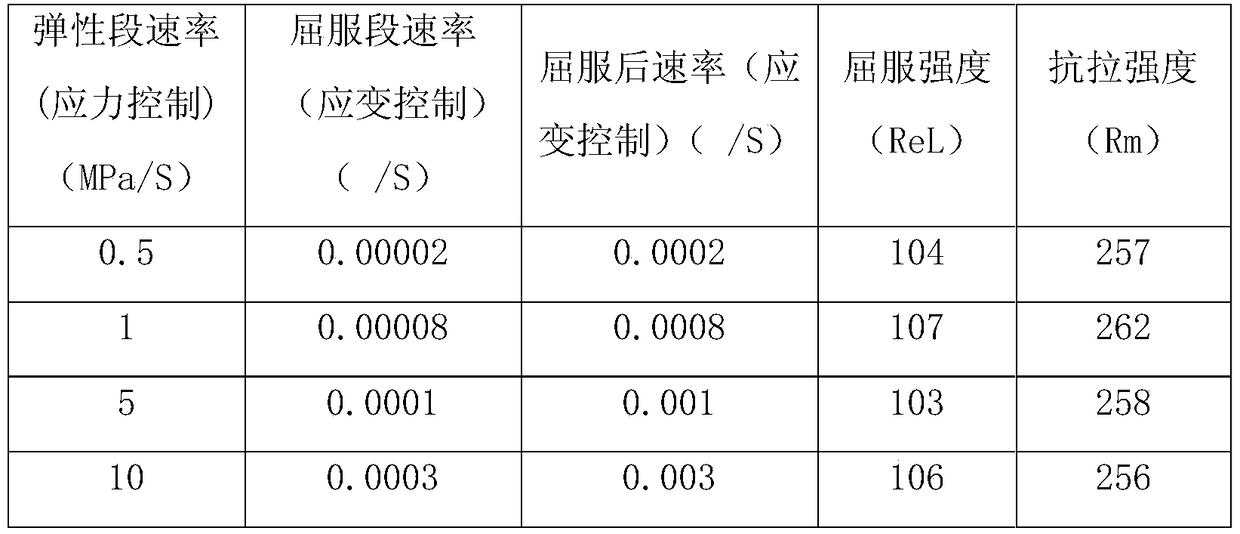

[0031] [Example 1] Apply the method of the present invention to Seismic Mild Steel Bars Performed Tensile Tests

[0032] Yield strength and tensile strength are the characteristics of the material itself, which can be obtained through static tensile tests. The lower the tensile rate, the more it can reflect the real performance of the material. However, too low a rate will affect the efficiency of material testing. For ordinary For metal materials, the tensile rate range stipulated in GB / T228 is suitable, but for the new material of anti-seismic mild steel, it is necessary to find a more suitable detection rate.

[0033] Combined with the physical tensile test, the anti-seismic mild steel is made into the actual structural parts, and the physical tensile test is carried out on the special tensile test equipment, and the obtained The yield strength of the anti-seismic mild steel bar is 104MPa, and the tensile strength is 258MPa. Through field tests, the average rate of physi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com