A turn-off scr device with latch-up resistance

A technology of anti-latch-up and ability, which is applied in the electronic field, can solve the problems of low maintenance voltage and burn-out devices, etc., and achieve the effect of reducing gain and preventing latch-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

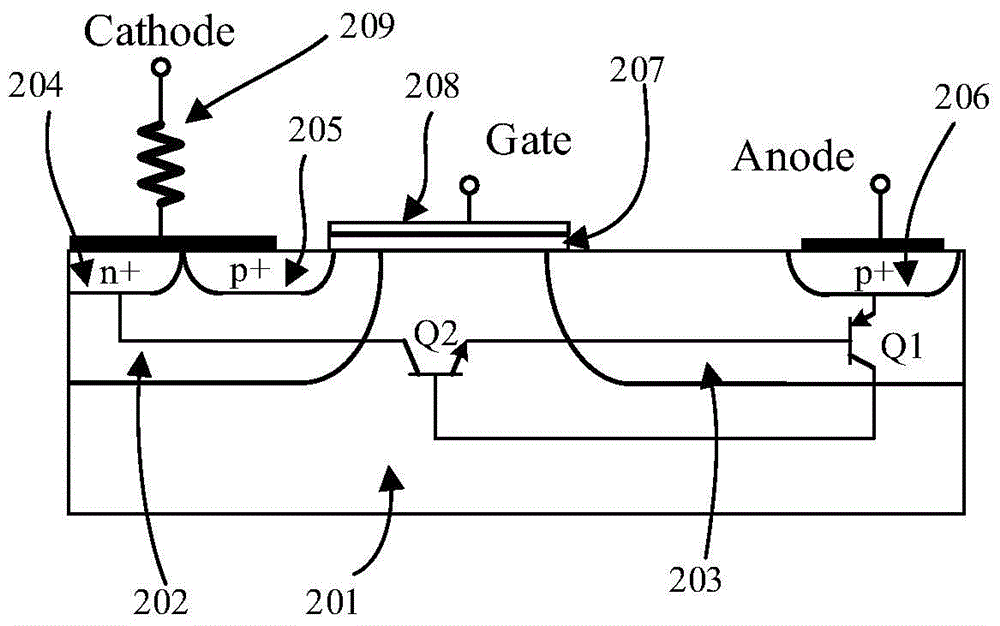

[0021] Such as figure 2 As shown, it is a schematic structural diagram of this example, including a P-type substrate 201, two N-type well regions 202 and 203, two P-type heavily doped regions 205 and 206, an N-type heavily doped region 204, and a gate oxide layer. 207 , polysilicon gate 208 and resistor 209 . Wherein the resistance value of the resistor 209 is relatively small. The two N-type well regions 202 and 203 are located on the P-type substrate 201, the N-type heavily doped region 204 and the first P-type heavily doped region 205 are located on the first N-type well region 202, and the first P-type The heavily doped region 205 is located on the side close to the gate, the gate oxide layer 207 is located on the P-type substrate 201, between the first P-type heavily doped region 205 and the second N-type well region 203, and the second P-type The heavily doped region 206 is located on the second N-type well region 203 . One end of the resistor 209 is connected to the...

Embodiment 2

[0026] Such as Figure 4 As shown, in this example, on the basis of the structure of Embodiment 1, a second N-type heavily doped region 210 is also provided on the second N-type well region 203, and the second N-type heavily doped region 210 is located in the In the second N-type well region 203 , located on the right side of the second P-type heavily doped region 206 , the second N-type heavily doped region 210 and the second P-type heavily doped region 206 together form an anode.

[0027] The working principle of this example is the same as that of Example 1, except that the second N-type heavily doped region 210 is set, which will reduce the gain of the parasitic PNP transistor Q1, improve the ability of the PMOS 301 to turn off the current, and improve the The ability of the device to discharge ESD current.

Embodiment 3

[0029] Such as Figure 5As shown, on the basis of Embodiment 1 of this example, an oxide layer 211 is provided on the P-type substrate 201, and the oxide layer 211 is located on the P-type substrate 201 and between the two N-type well regions 202 and 203. Down.

[0030] The working principle of this example is the same as that of Example 1. The difference is that the setting of the oxide layer 211 reduces the current on the substrate, and the current path is closer to the gate, which will help to improve the hole extraction capability of the PMOS channel, thereby improving the off-current of the PMOS301. The ability to improve the ability of the device to discharge the ESD current.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com