Waterproof electric connector

An electrical connector, waterproof electrical technology, applied in the direction of connection, two-part connection device, parts of the connection device, etc., can solve the problems of joint increase in overall volume, increase in shell thickness, etc., to reduce thickness, not easy Deformation, the effect of reducing the overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

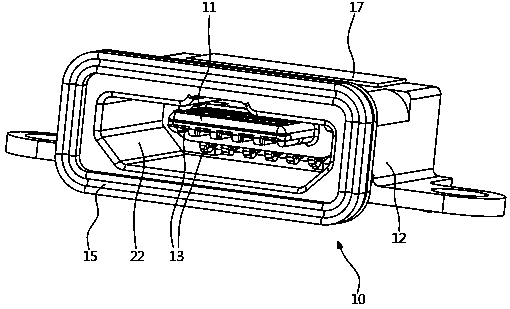

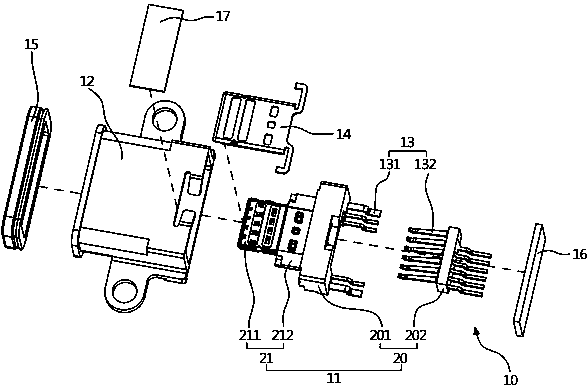

[0022] Please refer to figure 1 and figure 2 , figure 1 and figure 2 Shown are the waterproof electrical connector 10 and its exploded view of an embodiment of the invention respectively. The waterproof electrical connector 10 has a waterproof function, and can be applied to a waterproof portable electronic device (not shown), such as a waterproof smart phone. In this embodiment, the waterproof electrical connector 10 is a receptacle connector conforming to Micro USB 2.0 specification, but not limited thereto.

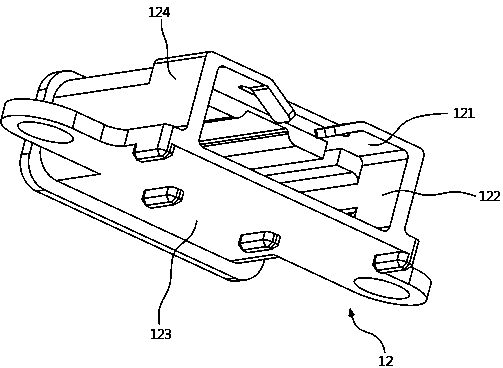

[0023] The waterproof electrical connector 10 includes an insulating body 11 , a metal shell 12 , a plurality of terminals 13 , a metal sheet 14 , a waterproof rubber ring 15 , a waterproof glue 16 and a film 17 . The insulating body 11 includes a rubber core 20 and a tongue 21 . The tongue 21 extends outward from the rubber core 20 . The metal shell 12 surrounds the insulating body 11 and forms an insertion space 22 . A plurality of terminals 13 are fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com