Cyclic stirring system for solid-liquid mixed mediums in storage tank

A medium circulation, solid-liquid mixing technology, used in mixers, fluid mixers, dissolution and other directions, can solve the problems of frequent maintenance of agitators, affecting production progress, etc., to achieve novel structure, ensure stable operation, and easy operation and use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

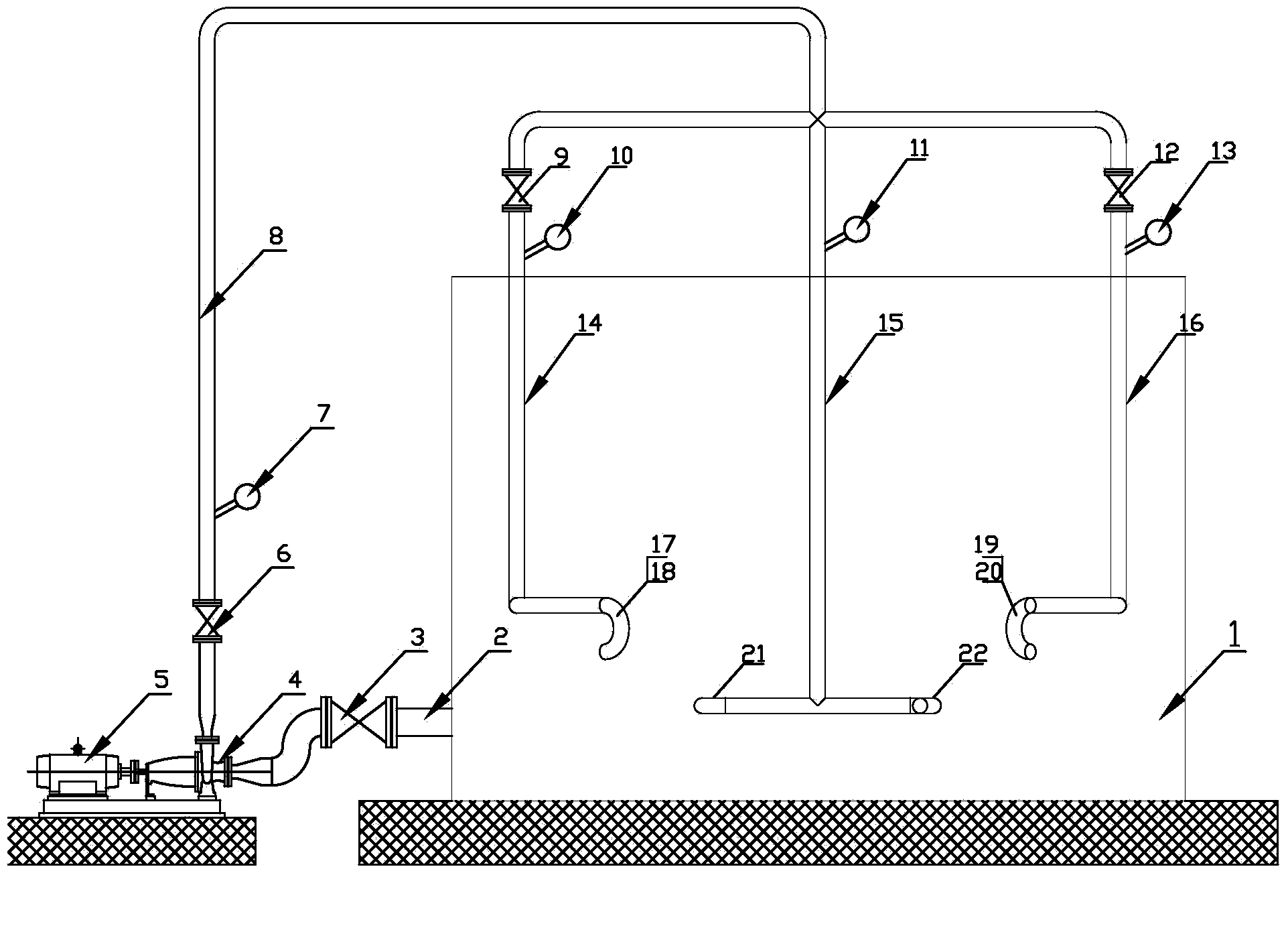

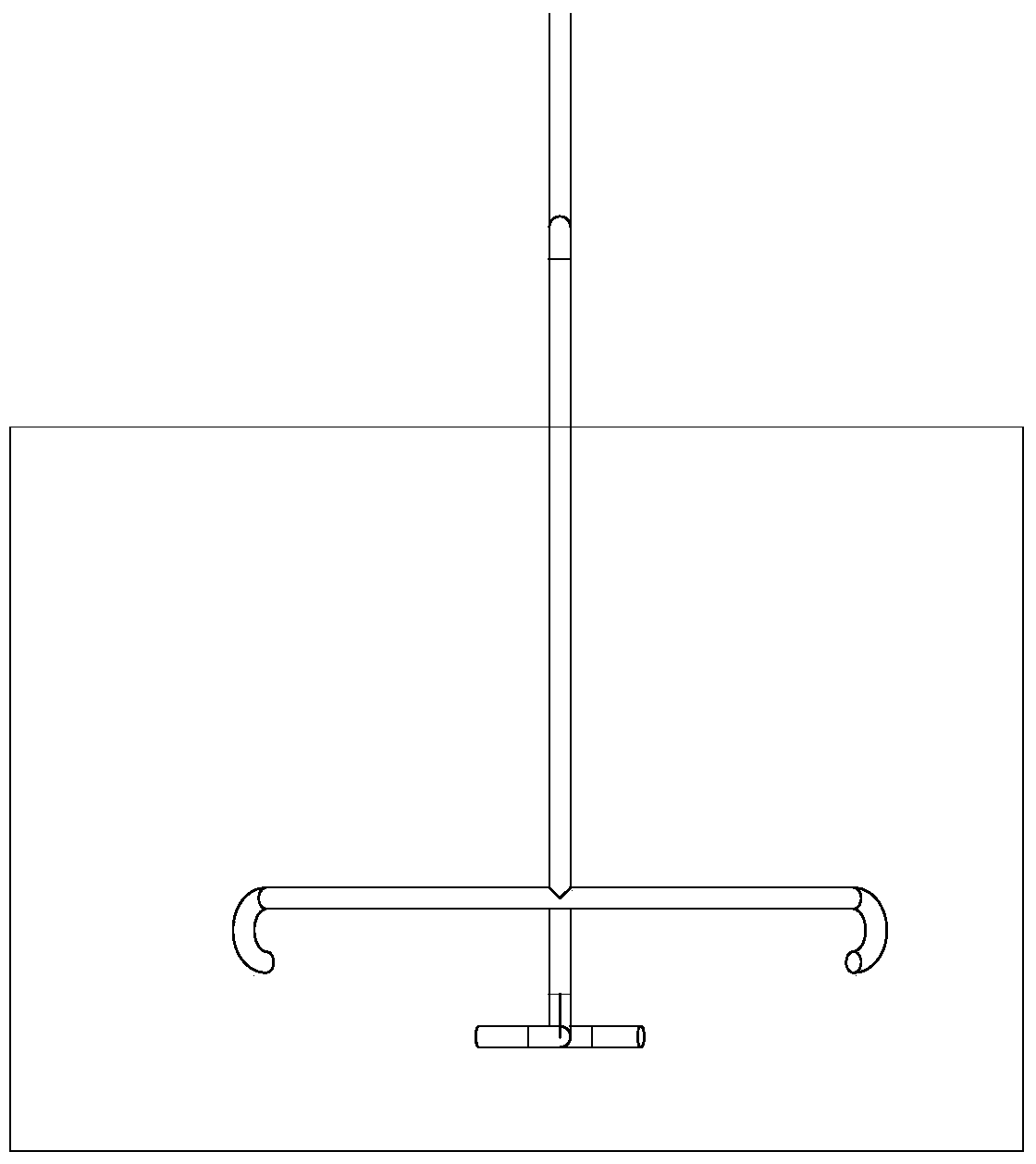

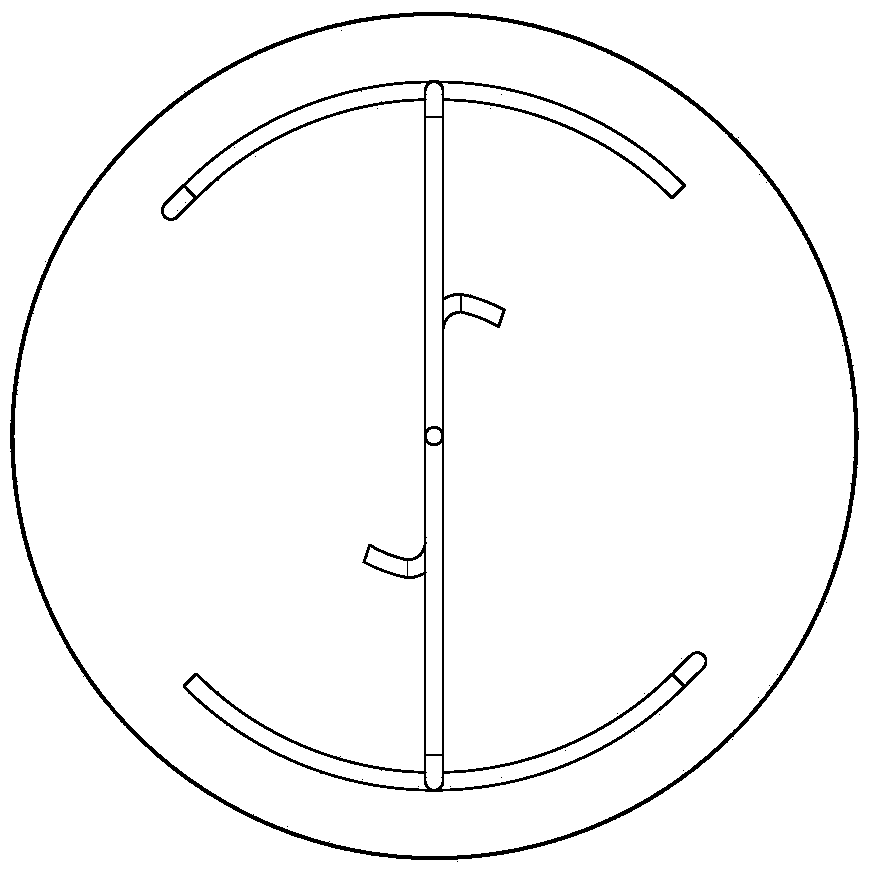

[0020] Such as Figure 1 ~ Figure 4 as shown,

[0021] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation methods and in conjunction with the accompanying drawings.

[0022] A circulating stirring system for solid-liquid mixed media in a storage tank, including a storage tank 1 for storing solid-liquid mixed media, which is a vertical storage tank, usually in the shape of a drum, which can be a closed structure or an open structure .

[0023] On the lower tank wall of the mixed medium storage tank 1, a circulating liquid pump inlet pipe 2 is drawn out and set, which is connected to the inlet of the circulating liquid pump 4, and is set on the circulating liquid pump inlet pipe between the two The inlet regulating valve 3 of the circulating liquid pump, driven by the motor 5, the circulating liquid pump does work on the medium in the pump, so that the medium obtains a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com