Material mixing system

A material mixing and material technology, applied in the mechanical field, can solve the problems of unstable flow, high pressure, uneven material pushing, etc., and achieve the effect of avoiding uneven mixing, high pumping pressure and accurate mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

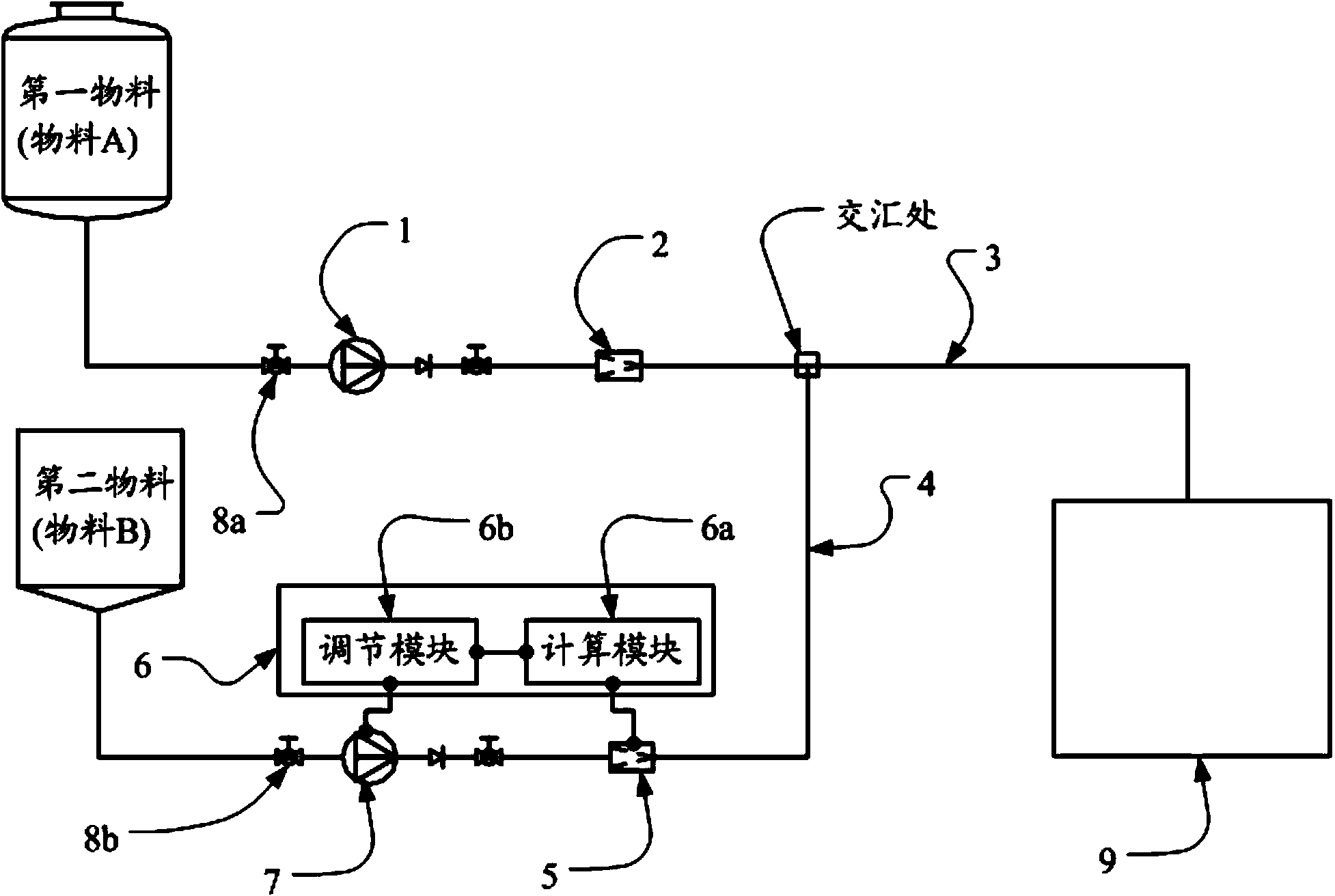

[0039] The embodiment of the invention discloses a material mixing system, which can make the ratio of two materials meet the preset mixing ratio, make the mixing more accurate, and avoid the problem of uneven and inaccurate mixing.

[0040] see figure 1 , an embodiment of a material mixing system in an embodiment of the present invention includes:

[0041] Discharge pump 1, first flowmeter 2, second flowmeter 5, multistage pump 7, first pipeline 3, second pipeline 4, adjustment module 6b and calculation module 6a;

[0042] The discharge pump 1 is connected to the first flow meter 2 through the first pipeline 3;

[0043] The multistage pump 7 is connected with the second flow meter 5 through the second pipeline 4;

[0044] The discharge pump 1 is used to pump the first material;

[0045] The multistage pump 7 is used to pump the second material;

[0046] The first flowmeter 2 is used to measure the first flow rate of the first material in the first pipeline 3;

[0047] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com