Spherical ring rolling machine

A technology of ring rolling machine and ball type, applied in the field of ball type ring rolling machine, can solve the problems of low precision of finished products, lack of precise measuring devices, etc., and achieve the effect of wide range of uses, improving quality and production efficiency, and ensuring precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

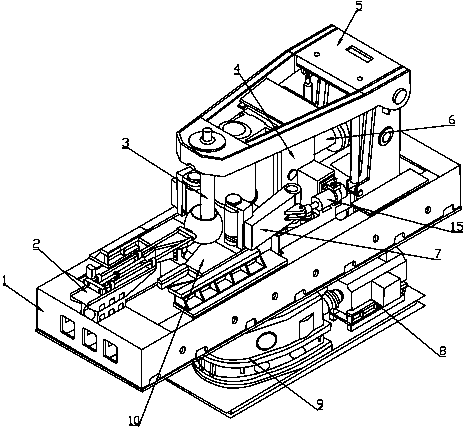

[0023] Such as figure 1 , Figure 10 As shown, the present invention includes a bed 1 , a driving device, a measuring device 2 , a bracket 10 , a mandrel 3 , a main roll seat 4 , a bracket 5 and a main feed oil cylinder 6 . The driving device includes a speed reducer 9 and a main motor 8 . The driving device is installed under the bed 1. A measuring device 2, a bracket 10, a mandrel 3, a main roll stand 4, a main feed cylinder 6 and a support 5 are arranged in sequence from left to right above the bed 1.

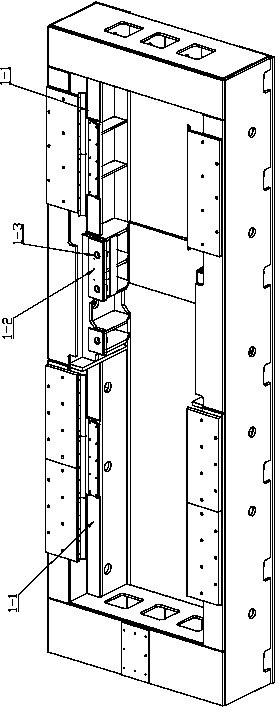

[0024] Such as figure 2 As shown, the inner wall of the bed 1 is provided with a slide rail 1-1 and a fixed plate 1-2, and the fixed plate 1-2 is provided with a fixed hole 1-3.

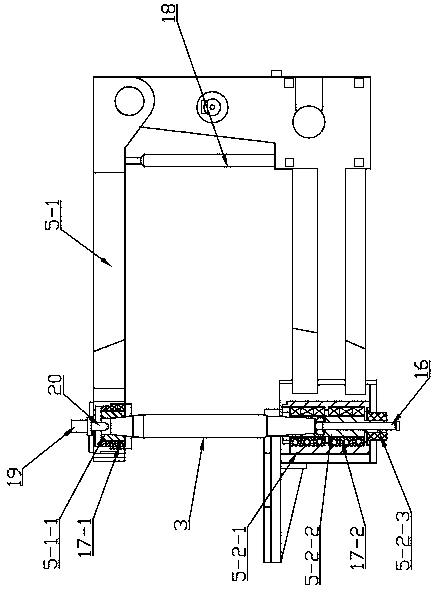

[0025] Such as image 3 As shown, the bracket includes a support 5-2 and a support arm 5-1, one end of the support arm 5-1 is hinged on the support 5-2 and can rotate along the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com