Driving device of plastic sole molding extrusion mechanism

A driving device and molding machine technology, which is applied in the field of extrusion mechanism driving devices in plastic shoe sole molding machines, can solve the problems of difficult processing and assembly, low transmission efficiency, high technical requirements for processing and assembly workers, and reduce processing and assembly. Difficulty, the effect of improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

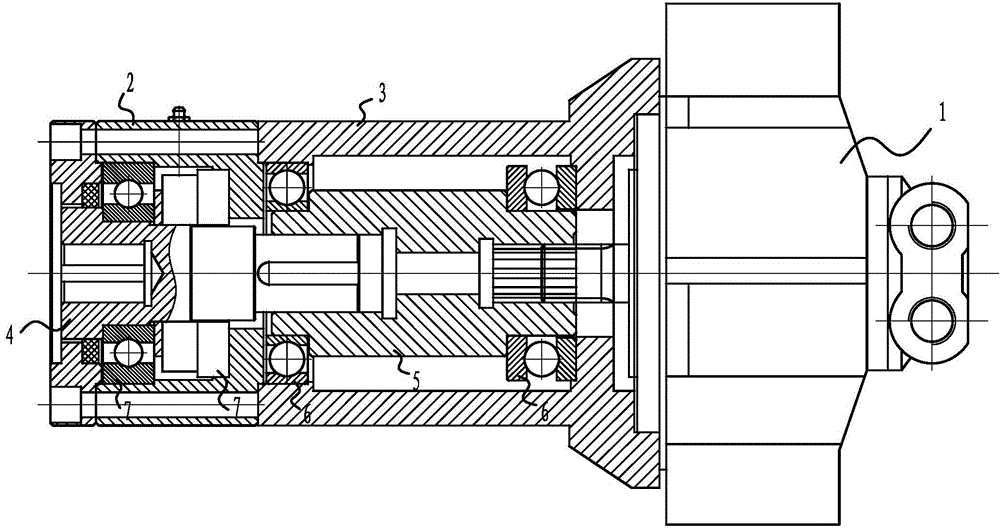

[0008] like figure 1 As shown, the driving device of the extrusion mechanism of the plastic sole molding machine includes a power device 1 and a transmission mechanism. The power device 1 is a hydraulic motor, and the transmission mechanism includes a cylindrical connection seat 2 and a cylindrical motor seat 3. 1. Drive the transition shaft 4 and the power transmission shaft 5, the connecting seat 2 and the motor seat 3 are preferably cylindrical with the same diameter, and the connecting seat 2 and the motor seat 3 can be integrally arranged, but for the convenience of production, the The connecting base 2 and the motor base 3 are preferably arranged separately, and are detachably and fixedly connected to each other.

[0009] The transmission shaft 5 is rotatably and coaxially arranged in the motor base 3 through a pair of front and rear transmission shaft 5 support bearings. The outer walls of both ends of the transmission shaft 5 are provided with shoulder steps, and a pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com