Three-dimensional printer frame

A technology of 3D printers and racks, applied in the field of 3D printers, can solve the problems of rough 3D printing products, difficult processing, and long processing cycle, and achieve the effects of improving space utilization, large printing range, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

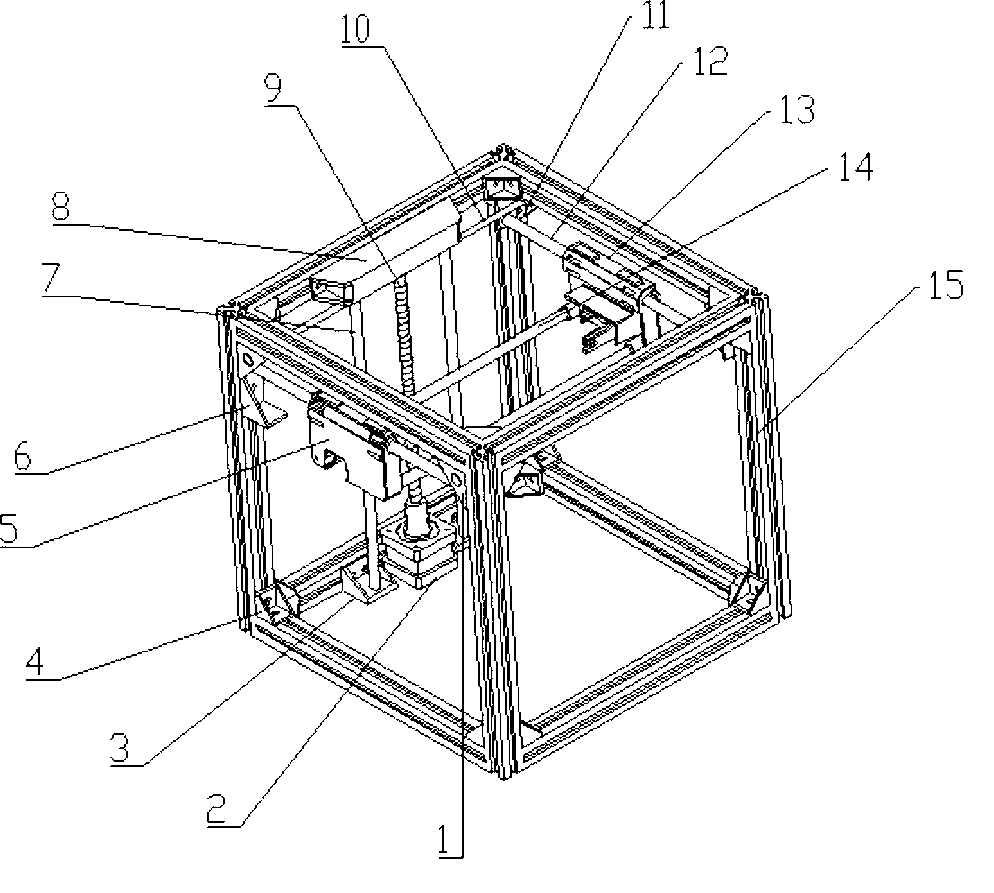

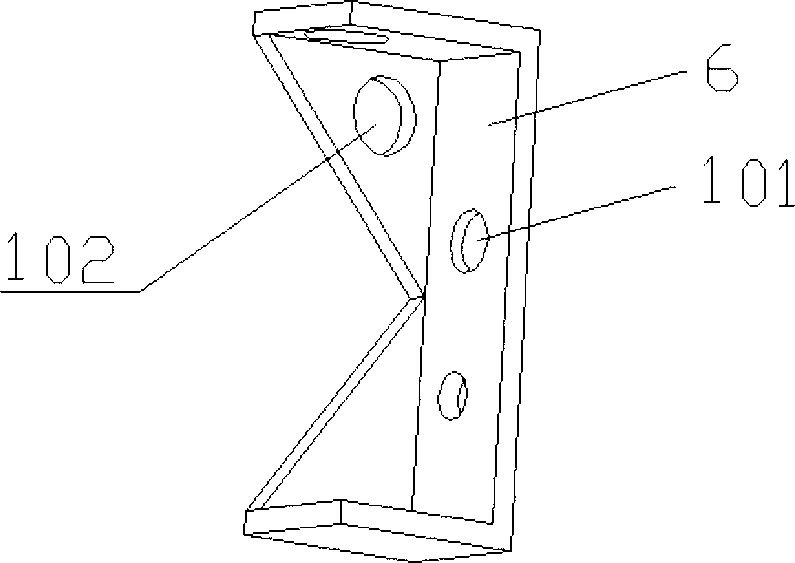

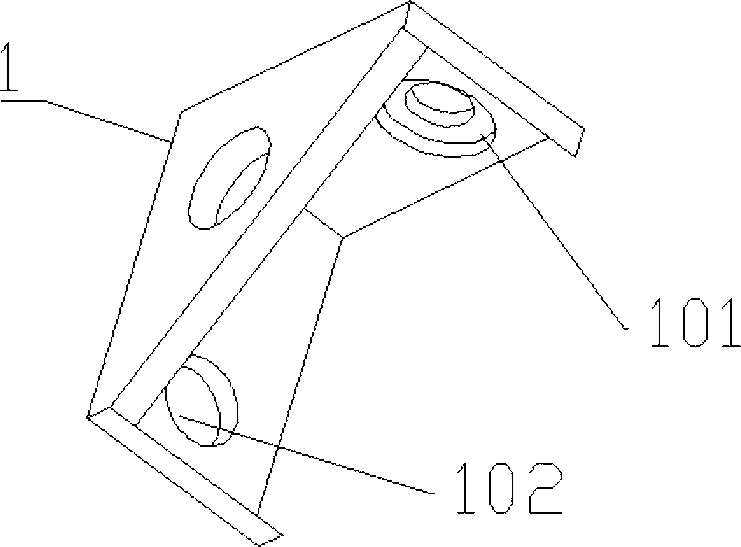

Embodiment 1

[0021] The three-dimensional printer frame of the present embodiment includes an X-axis slide bar 14, a Y-axis slide bar 12, a Z-axis slide bar 7, a Z-axis threaded rod 9, a locking member, a connecting rod, and a conveyor belt support shaft 10, and the locking member includes a bottom bracket Frame 3, top bracket 8 and fixing piece; Connecting rod is provided with 12, and connecting rod forms three-dimensional frame 15 as edge, and the connecting rod that constitutes three-dimensional frame 15 is connected by fixing piece in two, each vertex of three-dimensional frame 15 There are three fixing parts; the top bracket 8 is fixedly connected with the connecting rod at the top rear of the three-dimensional frame 15, and the bottom bracket 3 is fixedly connected with the connecting rod at the bottom rear of the three-dimensional frame 15; the Z-axis slide bar 7 passes through the bottom bracket 3 and the top The bracket 8 is fixed; the bottom end of the Z-axis threaded rod 9 is fix...

Embodiment 2

[0027] The present embodiment is except following difference other with embodiment one:

[0028] The connecting rod is a 2020 aluminum profile connecting rod.

[0029] When in use, fix the Z-axis drive motor on the three-dimensional frame and lower it to the connecting rod, drive the Z-axis threaded rod, and make the printing platform move vertically up and down along the Z-axis slide bar; fix the Y-axis drive motor on the right rear connecting rod of the three-dimensional frame On the top, drive the conveyor belt support shaft through the conveyor belt, and further drive the holder through the conveyor belt to slide horizontally along the Y-axis slide bar; fix the X-axis drive motor on the right holder, and drive the consumable extrusion device fixed on the motor bracket through the conveyor belt Move the slider horizontally along the X axis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com