Method for automatically spraying glue to seat

A glue-spraying and automatic technology, applied in the direction of spraying device, laminating device, lamination, etc., can solve the problems of uneven quality of finished products, difficult to standardize production, low work efficiency, etc., to achieve stable product quality, avoid direct damage, production Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

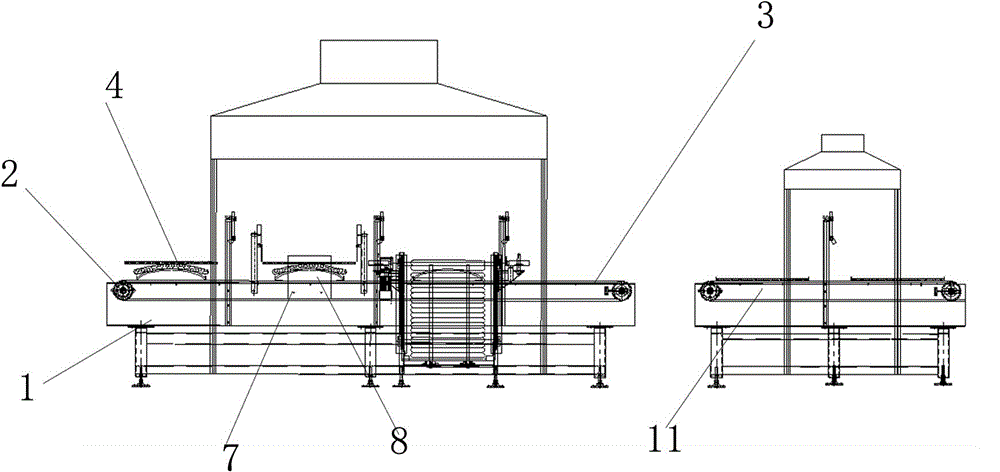

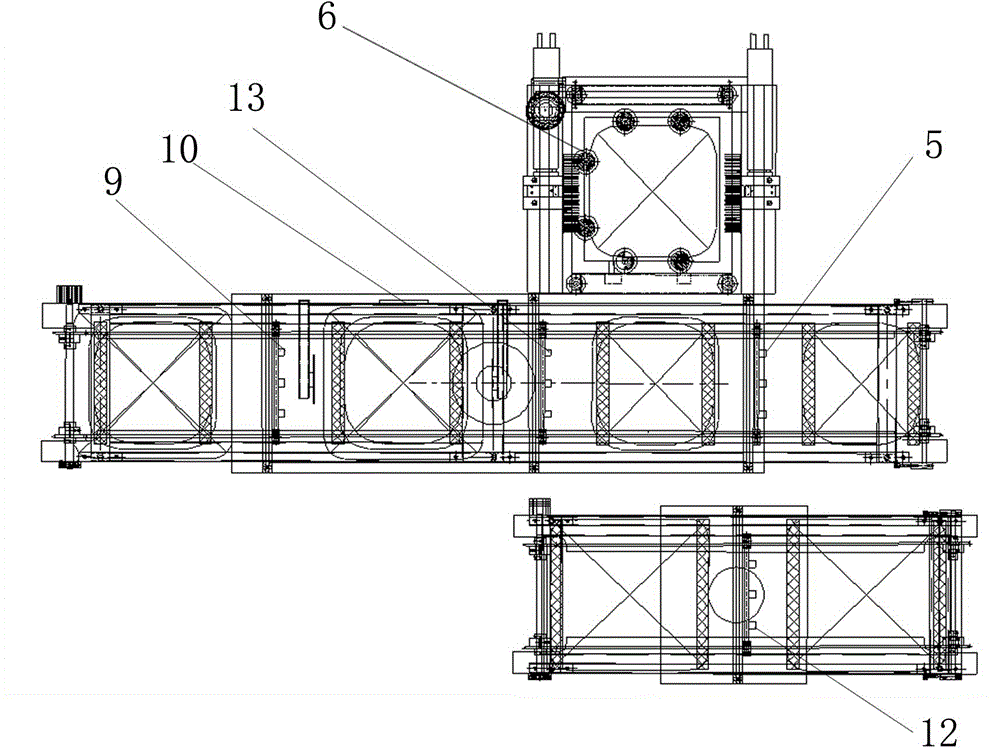

[0011] like figure 1 and 2 As mentioned above, the seat automatic glue spraying device of the present invention includes a main mechanism and a secondary mechanism.

[0012] The main mechanism includes a frame 1. A conveyor belt 3 driven by a motor 2 is set on the frame 1. The conveyor belt 3 moves from right to left. The wooden board 4 is placed on the rightmost end of the conveyor belt 3 and is conveyed to the left by the conveyor belt 3. The first inductive automatic glue spraying head 5 is arranged above the middle part of the frame 1 for spraying glue on the upper surface of the plank 4 . After spraying the glue, the automatic cotton feeding mechanism 6 sends the cotton cloth to the top of the plank 4 and compresses it. The left side of the first inductive automatic glue spray head 5 is provided with a second inductive automatic glue spray head 13, which is used to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com