Milk powder container with integrated inner plug and outer cover

A milk powder can and integrated technology, which is applied in the field of food packaging, can solve the problems of weak sealing ability, large direct impact deformation, large cover top area, etc., achieve good sealing, improve rigidity and strength, and store for a long time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

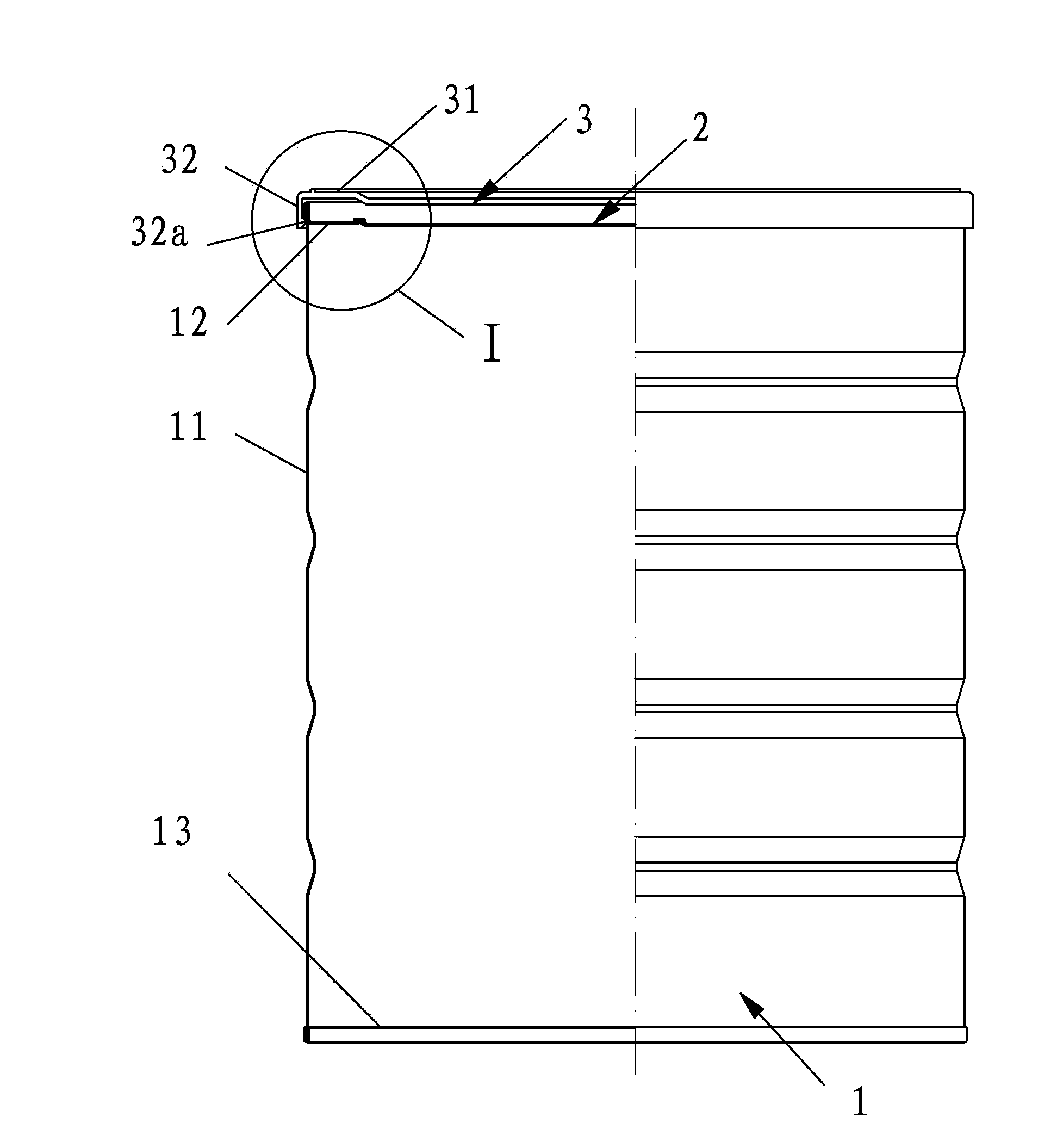

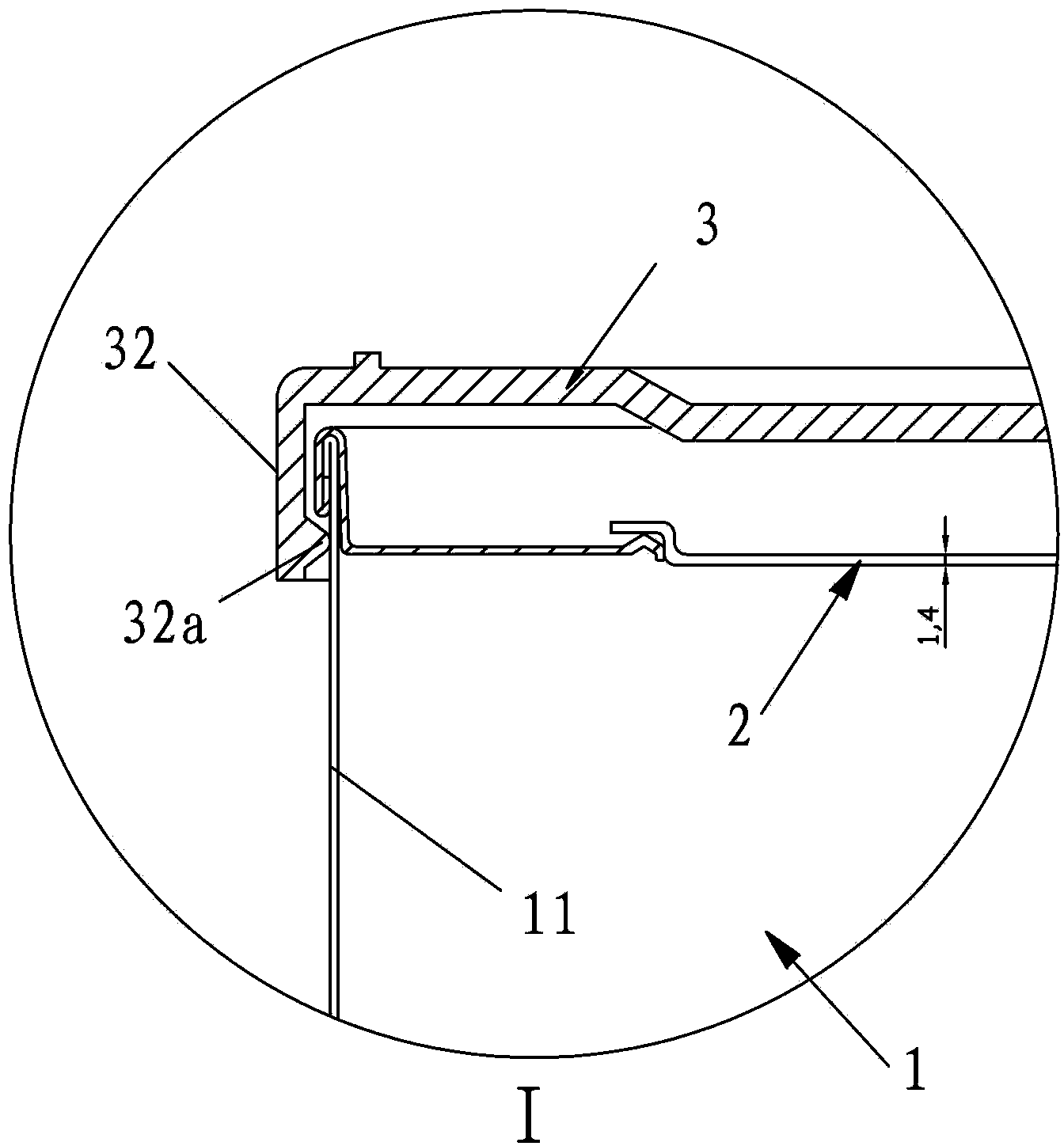

[0029] Such as Figures 1 to 3 As shown, the existing milk powder mainly consists of a tank body 11, a tank bottom 13, a tank top 12 with an opening, an inner plug 2 for closing the opening, and a plastic outer cover 3. The outer cover 3 is made of plastic material and basically made of metal material. The inner plug 2 is tightly plugged into the opening of the tank top 12 to form a seal. , The outer cover 3 forms a sealing surface with the wall and edge of the tank body 11, which can strengthen the sealing.

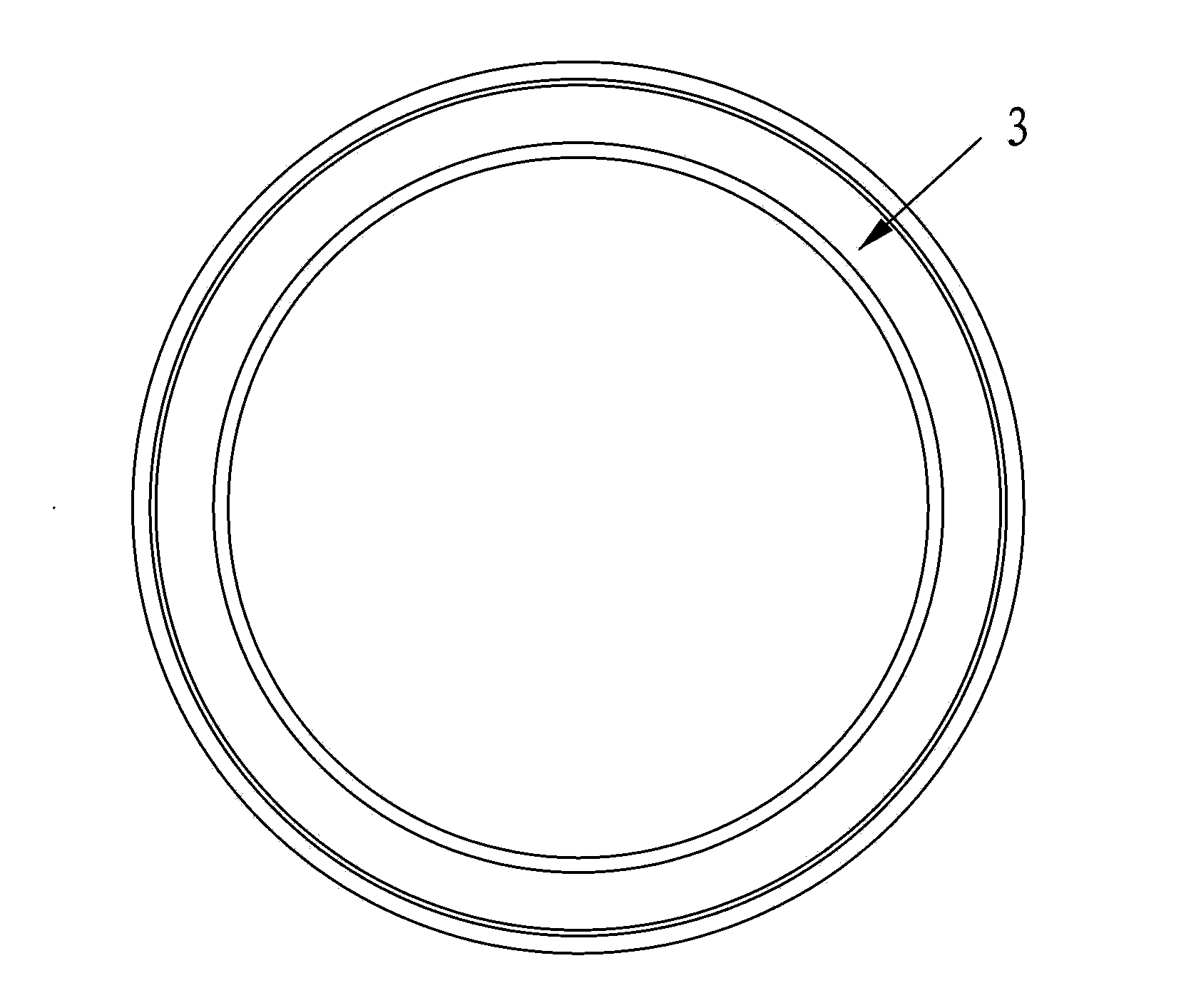

[0030] Figures 4 to 6 It is an integrated milk powder can with an inner plug and an outer cover of the present invention, which includes a tank body 1, an inner plug and an outer cover integrated cover 2, and a sealing film 3. The tank body 1 is composed of a tank body 11, a tank bottom 13, and a tank top with an opening. 12, the tank top 12 is provided with an upwardly protruding collar 12a, and the inner plug and the outer cover are combined together. The ring 23 i...

Embodiment 2

[0033] Figures 7 to 9 It is an integrated milk powder can with an inner plug and an outer cover of the present invention, which includes a tank body 1, an inner plug and an outer cover integrated cover 2, and a sealing film 3. The tank body 1 is composed of a tank body 11, a tank bottom 13, and a tank top with an opening. 12, the tank top 12 is provided with an upwardly protruding collar 12a, and the inner plug and the outer cover are combined together. The cover 2 includes a cover top 21, a cover ring 2, and an inner convex ring 23. Put the ring gap groove 24 of the tank top collar 12a, the bottom of the ring gap groove 24 is provided with a sealing ring 25, the groove where the sealing ring 25 is installed is slightly enlarged and a step-shaped stop is formed at the edge joint of the sealing ring 25 to prevent the sealing ring from 25 moves. A protruding ring 21a is provided on the cover top 21 corresponding to the inner flange 23, a flange 22a is provided on the inner sid...

Embodiment 3

[0035] Figures 10 to 12It is an integrated milk powder can with an inner plug and an outer cover of the present invention, which includes a tank body 1, an inner plug and an outer cover integrated cover 2, and a sealing film 3. The tank body 1 is composed of a tank body 11, a tank bottom 13, and a tank top with an opening. 12, the tank top 12 is provided with an upwardly protruding collar 12a, and the inner plug and the outer cover are combined together. The cover 2 includes a cover top 21, a cover ring 2, and an inner boss 23. Put the ring gap groove 24 of the tank top collar 12a, the bottom of the ring gap groove 24 is provided with a sealing ring 25, the groove where the sealing ring 25 is installed is slightly enlarged and a step-shaped stop is formed at the edge joint of the sealing ring 25 to prevent the sealing ring from 25 moves. The inner boss 23 is also provided with a cavity 26. On the top of the cover 21, a protruding ring 21a is provided at a place corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com