Deviation rectification mechanism based on track heavy-duty transport machine

A conveyor and deviation correction wheel technology, applied in the field of deviation correction mechanism, can solve the problems of processing welding and installation accuracy deviation, can not solve the problem of deviation correction, steel coil position deviation, etc., to correct the running track, avoid equipment scraping accidents, and reduce contact impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

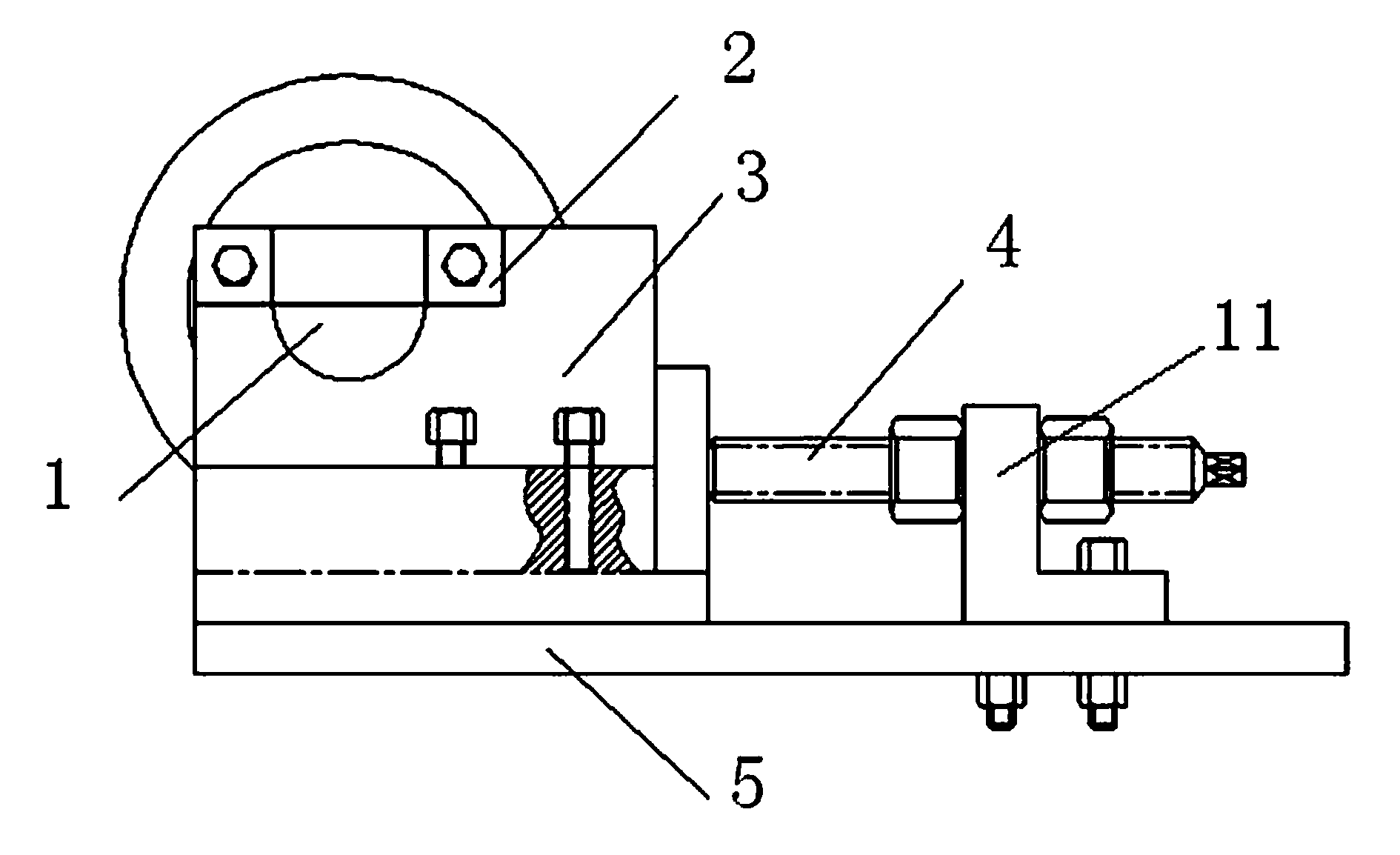

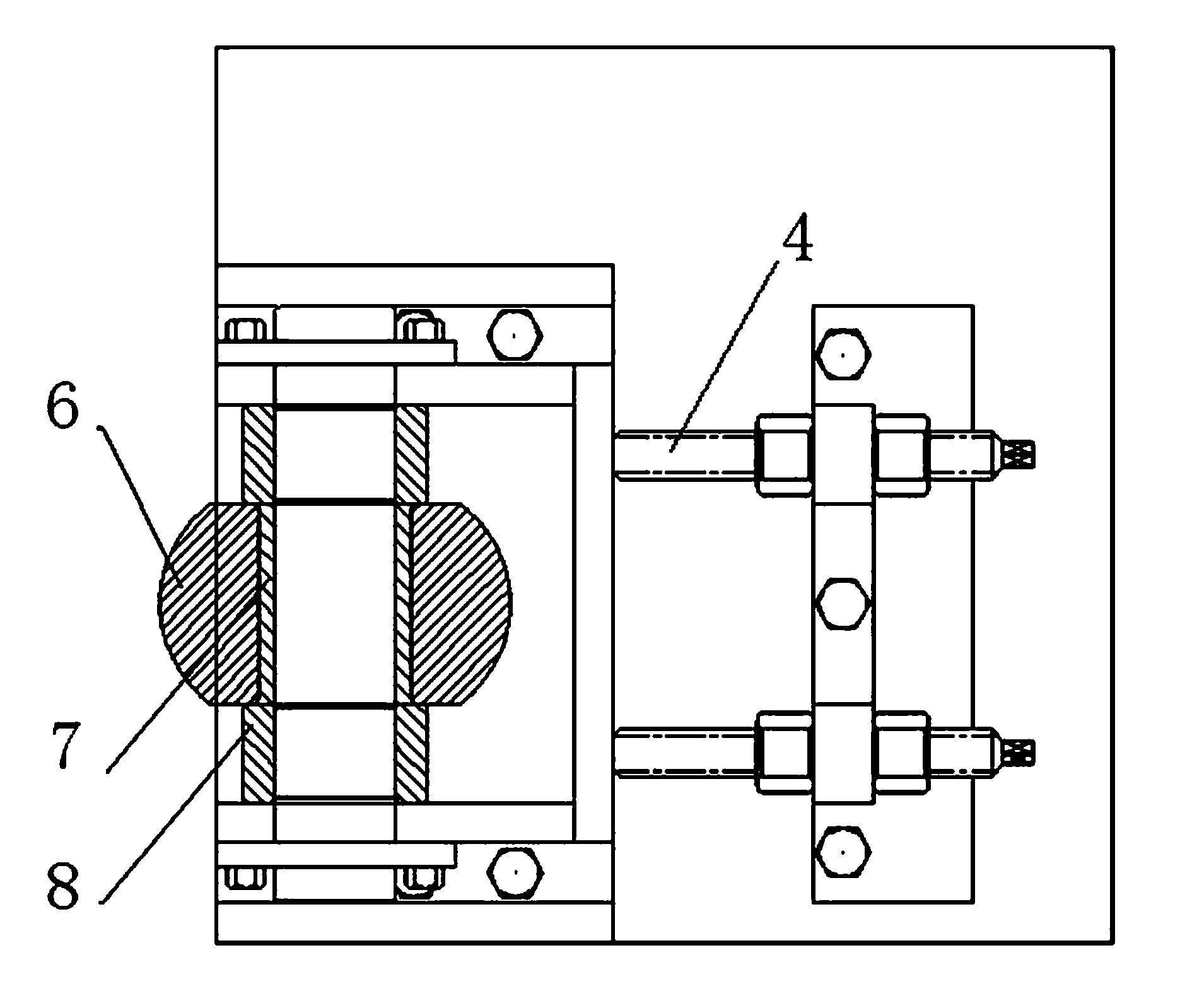

[0022] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

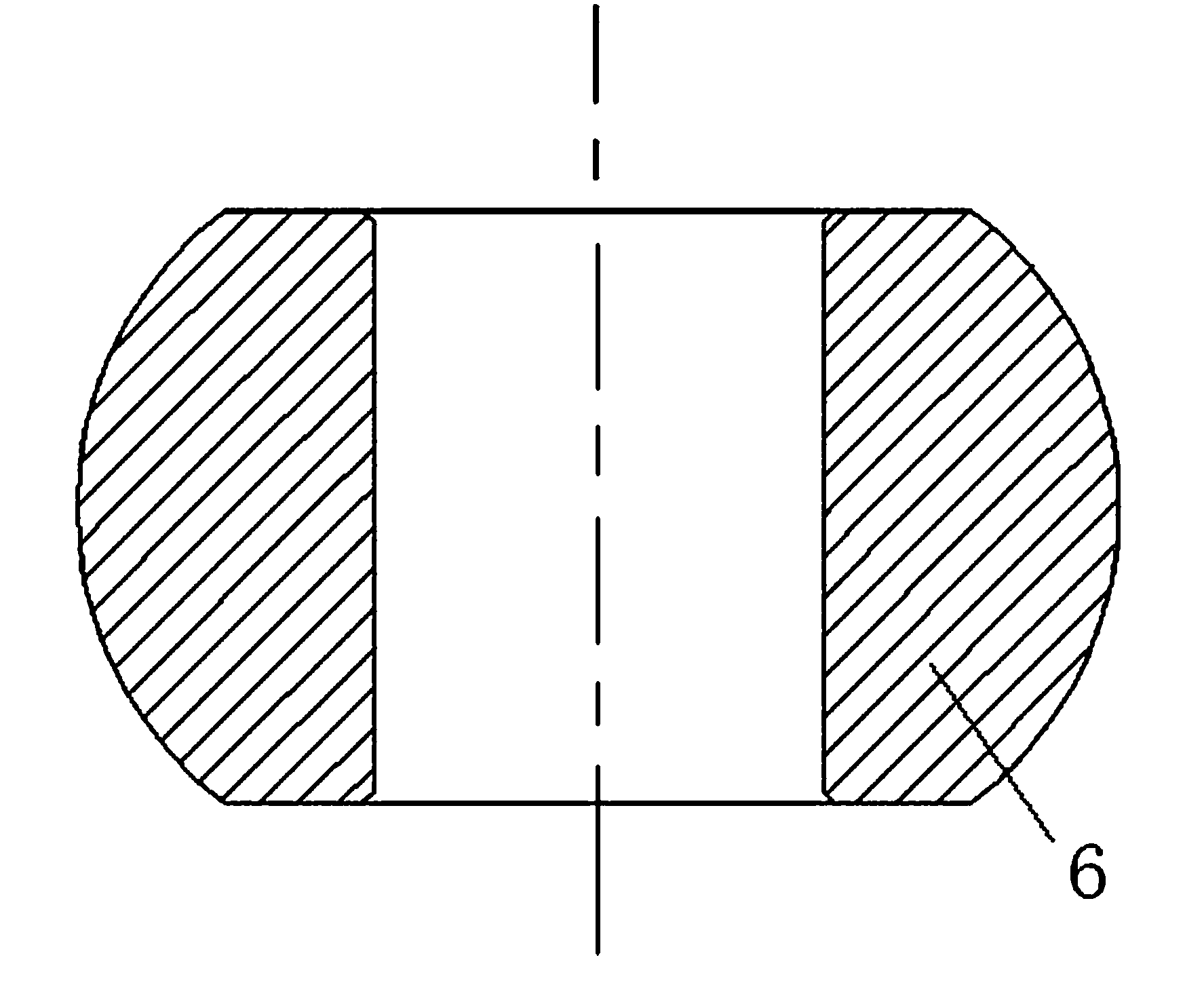

[0023] Such as Figure 1 to Figure 5 As shown, a correcting mechanism based on a tracked heavy-duty conveyor of the present invention includes a correcting wheel 6, which has a spherical shape, and the correcting wheel 6 is mounted on a bracket 3 through a central shaft 1, and the axial direction of the central shaft 1 Parallel to the running direction of the conveyor, the bracket 3 is installed on the support 5, and the support 5 is provided with an adjustment mechanism for adjusting the support 3.

[0024] By designing the correction wheel into a spherical shape and correcting the deviation in a way that the spherical surface is tangent to the plane, the buffer can be increased, the hard contact impact of the correction process can be avoided, and the damage to the correction mechanism can be reduced; in addition, the correction wheel is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com