Tempered glass substrate marking method and marking device

A technology for strengthening glass and substrates, which is applied in glass cutting devices, glass production, glass manufacturing equipment, etc., and can solve problems such as easy wear and tear of cutter wheels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

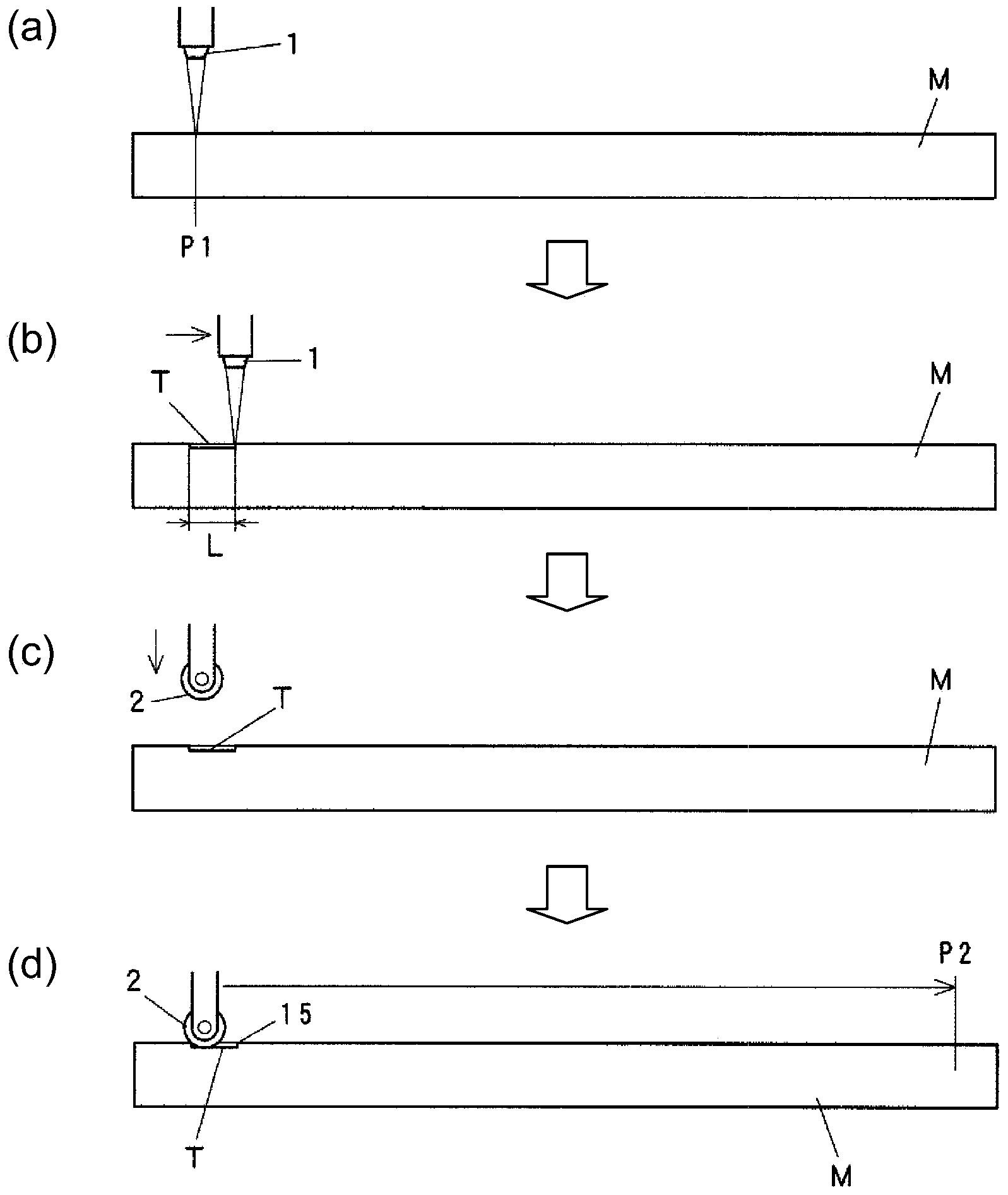

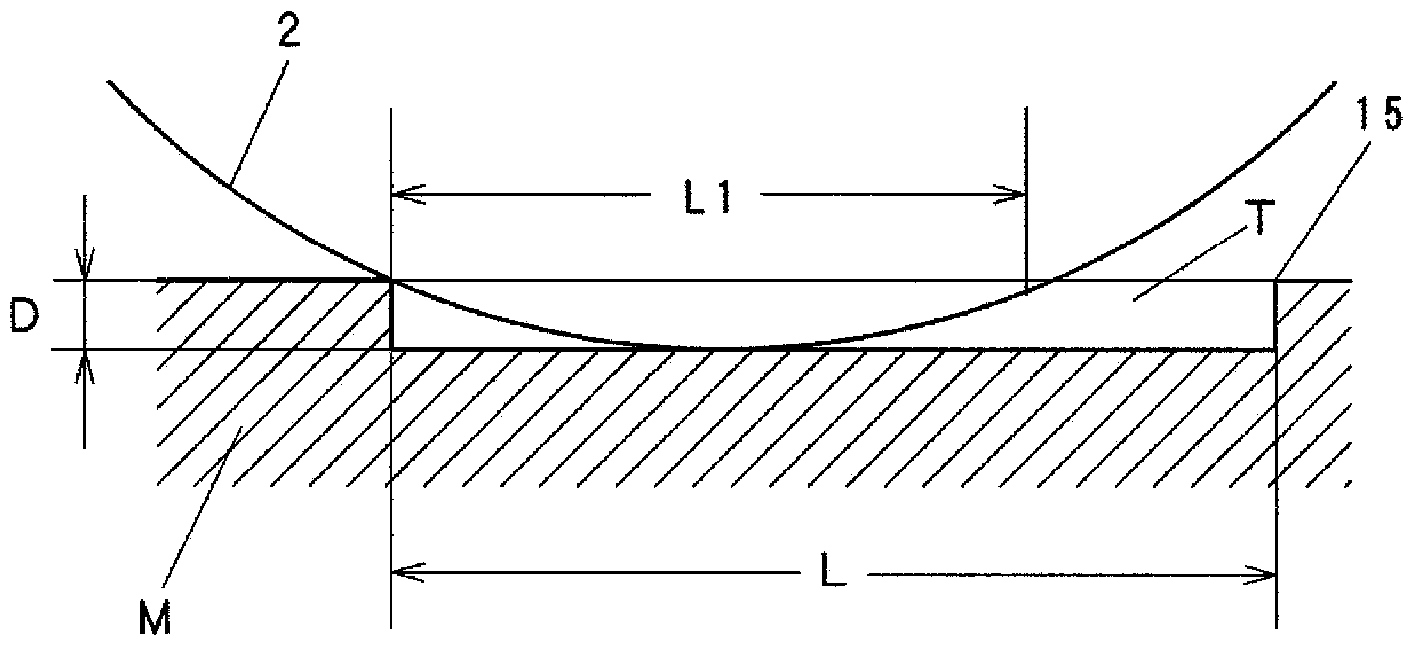

[0047] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation of the marking method and marking device for a strengthened glass substrate proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments , method, step, structure, feature and effect thereof, detailed description is as follows.

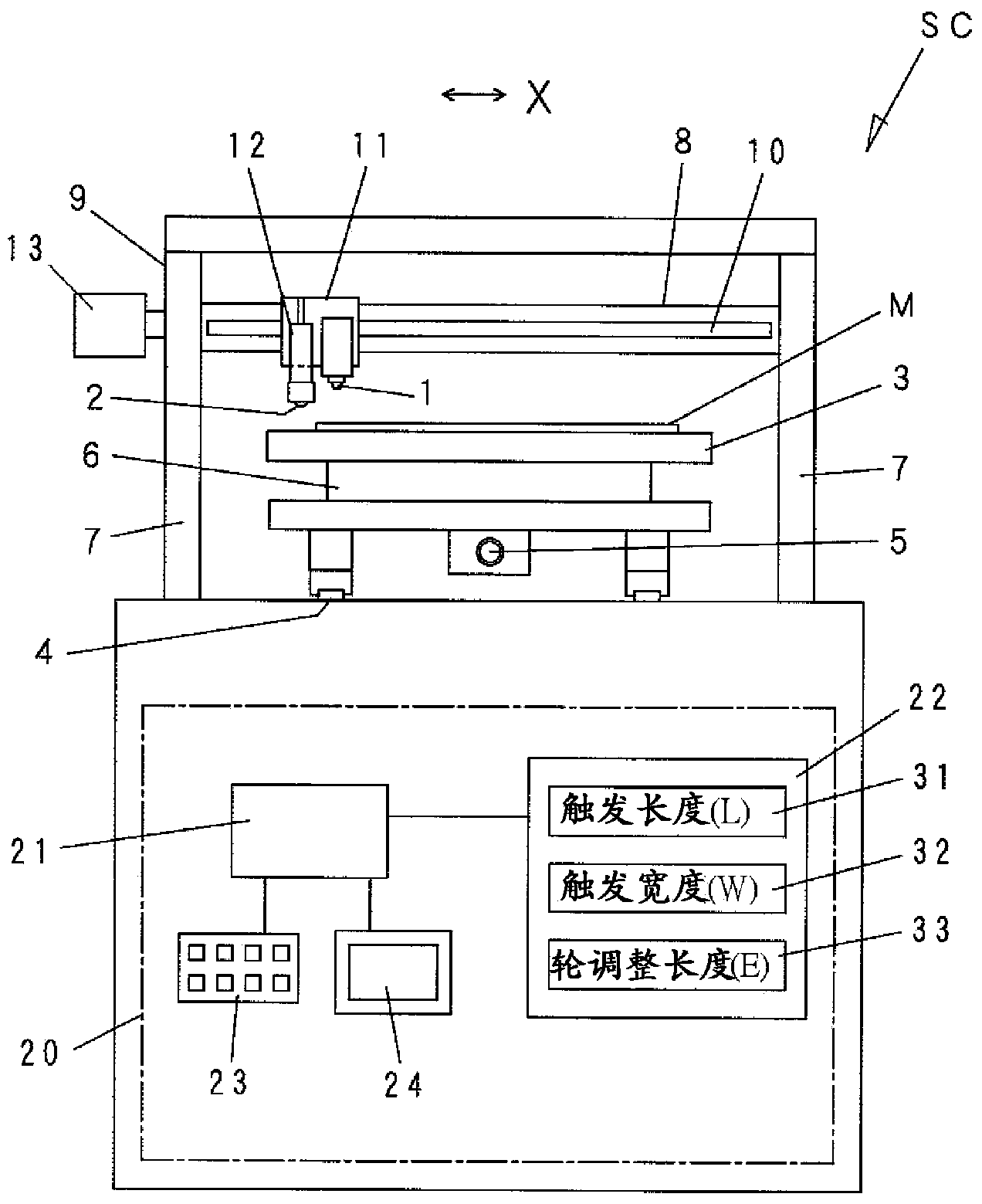

[0048] figure 1 It is a schematic diagram showing an example of a scribing apparatus used to form a scribe line on a strengthened glass substrate having a compressive stress layer on the substrate surface.

[0049] This scribing apparatus SC includes a stage 3 on which a strengthened glass substrate M is placed. The stage 3 is provided with a holding mechanism for holding the substrate M placed thereon at a fixed position. In this embodiment, as the holding mechanism, the substrate M is sucked and held b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap