Spiral photoelectric yarn cleaner

A yarn clearer and photoelectric technology, which is applied in the direction of optical testing flaws/defects, textiles and papermaking, etc. It can solve problems such as easy to miss flat yarn flaws, unable to monitor yarn diameter, etc., and achieve the effect of improving the identification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

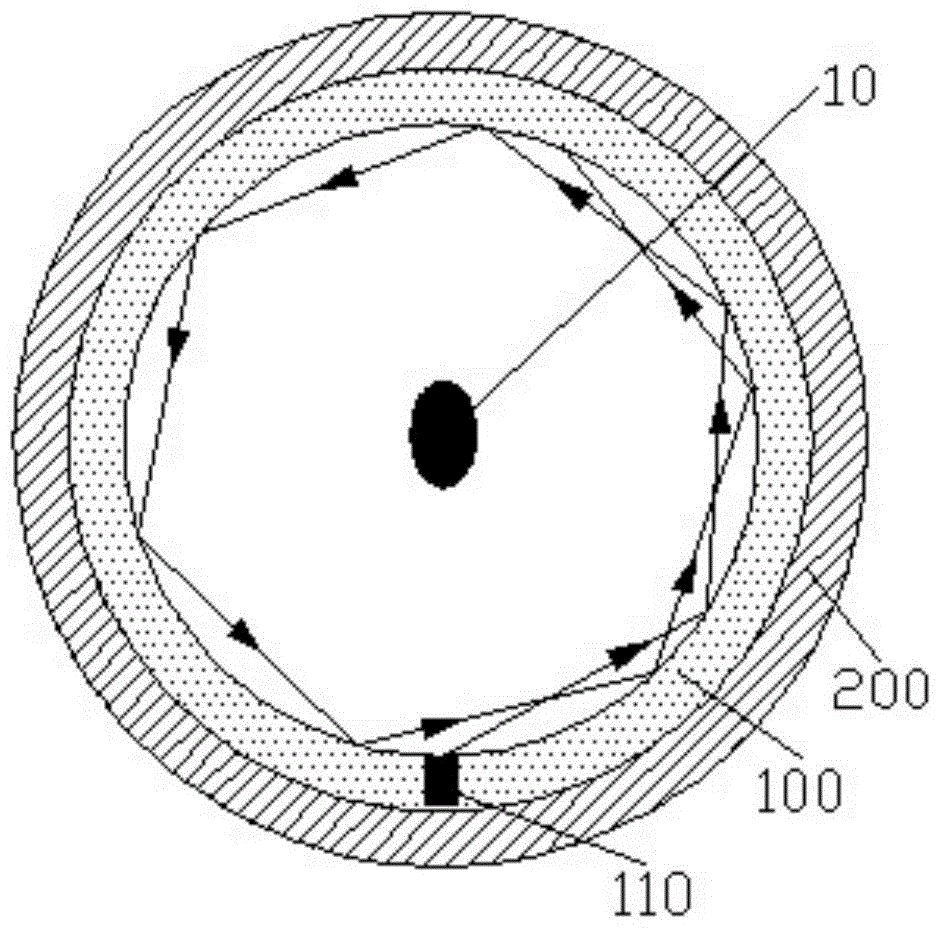

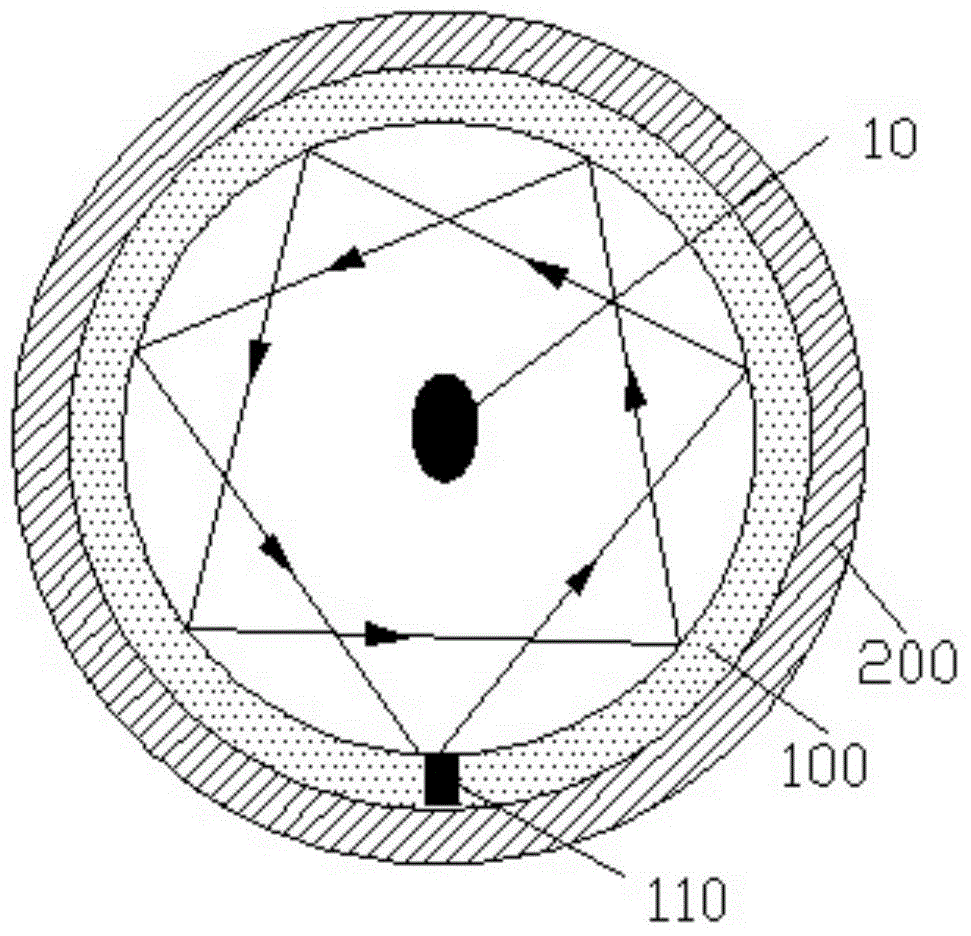

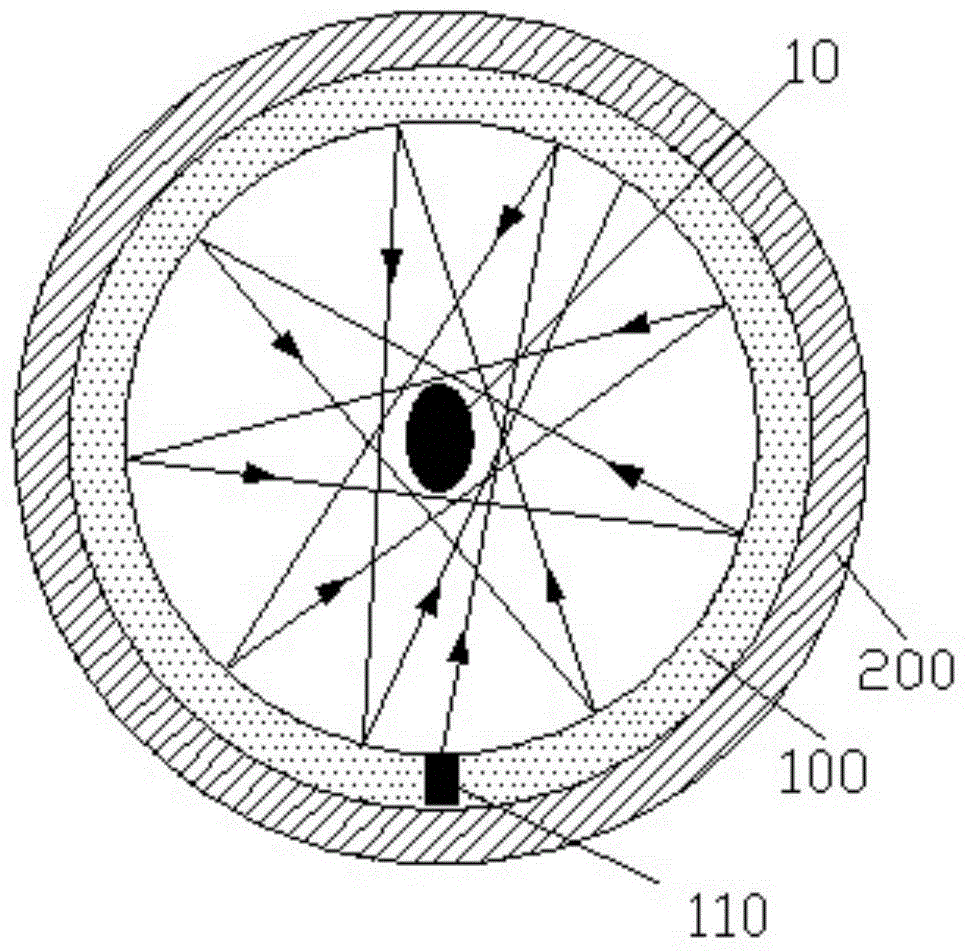

[0017] In this example, see figure 1 , the spiral photoelectric yarn clearer includes a monitoring ring 100 whose inner wall is provided with a reflective coating, the center of the monitoring ring 100 passes through the yarn 10 to be monitored, and the inner wall of the monitoring ring 100 is provided with a 100 is a rotatable optical emitting head 110 on a plane. The monitoring ring 100 is slidably arranged on an annular support 200 and driven to rotate by a driver. The two sides of the plane where the optical emitting head 110 emits light and scans are provided with monitoring devices. An optical monitoring device for emitting light from the optical emitting head 110.

[0018] For the above-mentioned spiral photoelectric yarn clearer, the light received and emitted by the optical monitoring device and the optical emitting head 110 is infrared rays, and the use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com