Lightweight floating floor for control of structure-borne noise in fixed installations

A fixed equipment, structure noise technology, applied in the direction of elastic floor, insulating layer, etc., can solve problems such as structure noise, achieve the effect of good noise reduction, save usable space, and good vibration isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

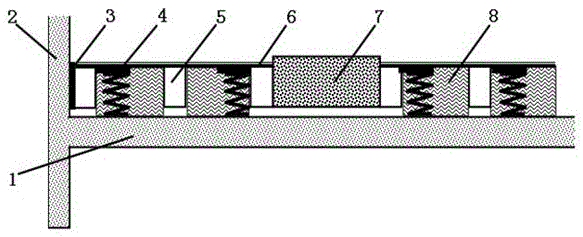

[0014] The lightweight floating floor of the present invention includes a sealant 3 , a vibration isolator 4 , a keel 5 , a sound insulation board 6 , a concrete base 7 and sound-absorbing cotton 8 . In the figure, 1 is the foundation (floor, ground, etc.), and 2 is the wall. Wherein the keel 5 is mostly made into a cross grid form, and can also be made into other forms according to actual requirements. Weld a steel plate on the lower surface of the keel that needs to place the fixed equipment, and pour concrete machine base 7 on this plate to ensure that it is fixed with the keel. Lay the sound insulation board 6 on the remaining keels, and fix the two, and also the sound insulation board 6 can be made into fritters and fixed on the keel respectively, which is conducive to maintenance and repair in the future. At an appropriate position of the keel 5 (usually at the intersection), it is connected with the foundation 1 through a vibration isolator 4 to provide support for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com