Engine cylinder head guard and engine assembly

An engine cylinder head and shield technology, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of high engine fuel consumption and excessive oil in the engine cylinder head shield, and achieve the effect of alleviating excessive fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The core of the present invention is to provide an engine cylinder head shield, which can alleviate the problem of high fuel consumption of the engine. Another core of the present invention is to provide an engine assembly comprising the above-mentioned engine cylinder head shroud.

[0031] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

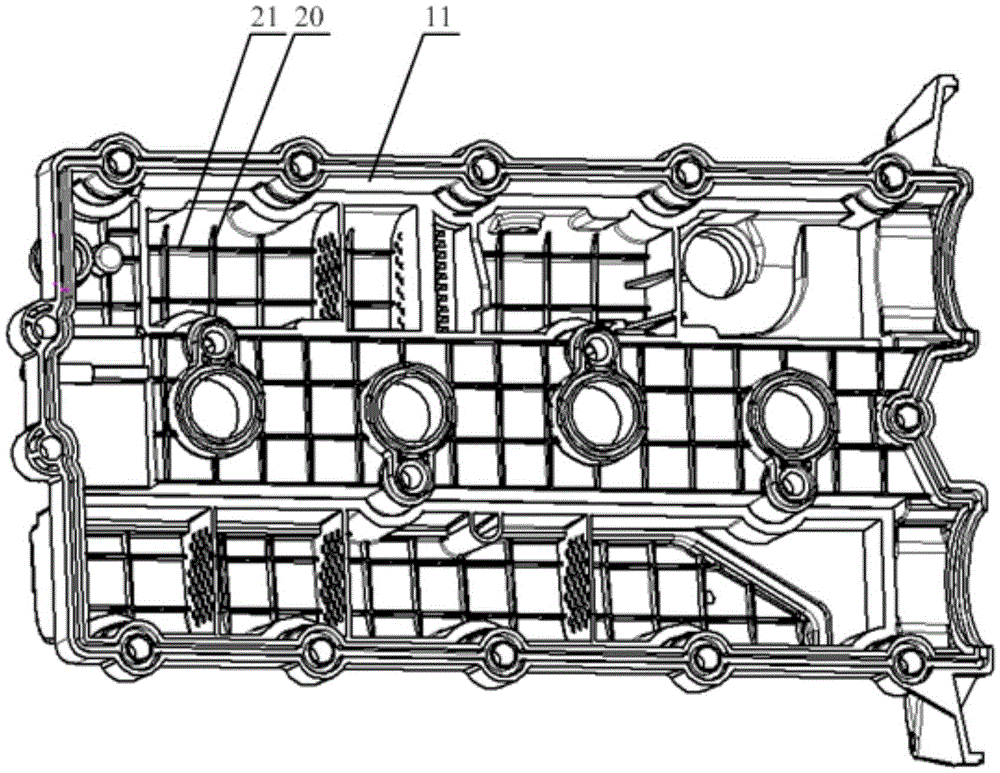

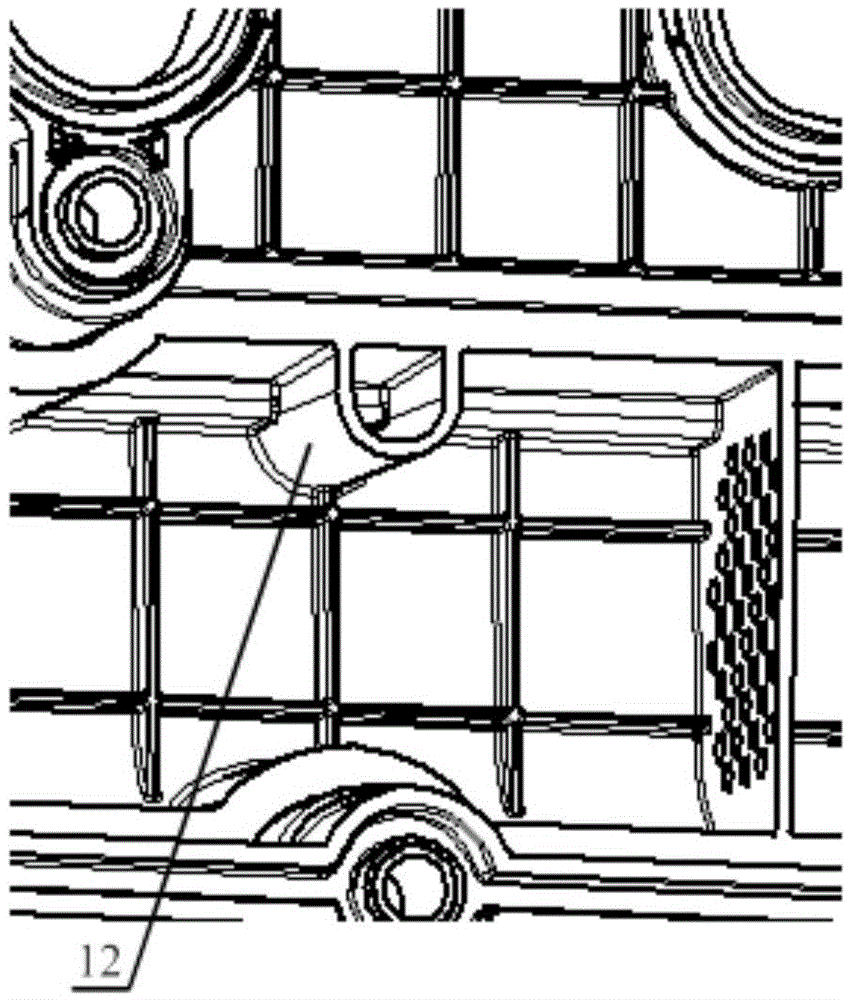

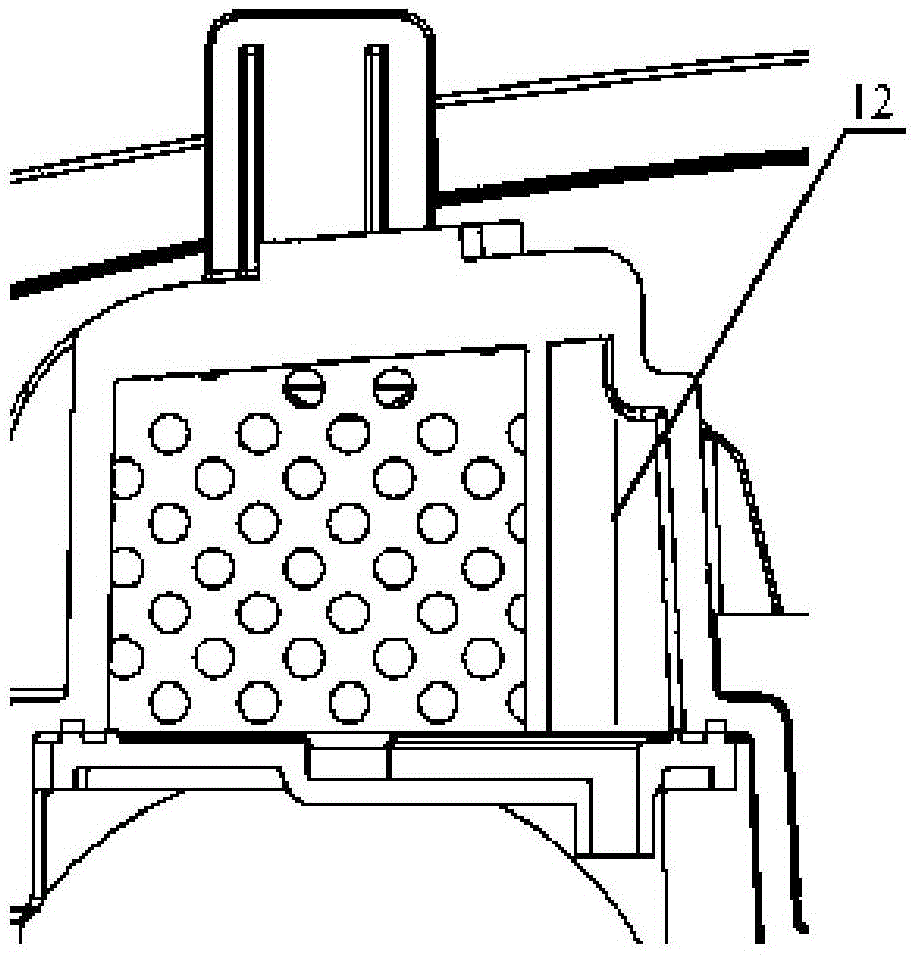

[0032] Such as Figure 1-4 As shown, the embodiment of the present invention provides an engine cylinder head shield, which includes a housing 11 and an anti-backflow mechanism, wherein:

[0033] The housing 11 has an oil and gas inlet and an oil return port. The blow-by gas in the crankcase enters the separation chamber in the housing 11 through the oil and gas inlet, and the separated oil flows back into the crankcase from the oil return port;

[0034] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com