Gas loss calculation method

A loss and gas technology, applied in the field of gas loss calculation, which can solve problems such as inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A gas loss calculation method, which includes the following steps:

[0051] 1) According to AQ1047-2007 "Direct Measurement Method of Gas Pressure in Underground Coal Seam of Coal Mine", the measured gas pressure is P=0.6MPa.

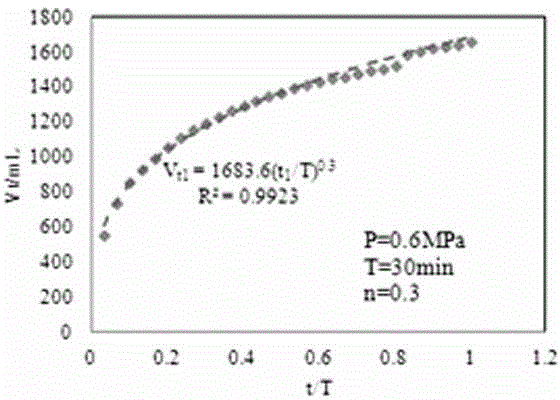

[0052] 2) Measure the coal seam gas content on site according to GB / T-23250 "Direct Determination Method of Coal Seam Gas Content Underground", and record the desorption time t (the time interval is 1min), and the cumulative desorption amount over time t V t (read the number every 1min),

[0053] Table 1 On-site gas desorption measurement table

[0054]

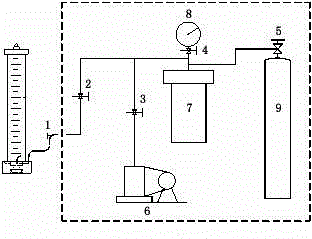

[0055] 3) Collect coal sample cuttings during drilling, wrap them in plastic bags and send them to the laboratory for corresponding adsorption and desorption tests; specifically:

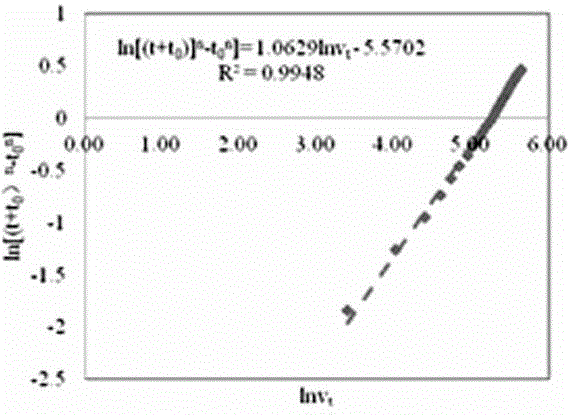

[0056] Put the collected coal sample drilling cuttings into the adsorption system, pre-evacuate for 10h, then fill with methane to the coal seam gas pressure P=0.6MPa, and let the adsorption balance for 24h, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com