Plane magneto-optical isolator

An isolator and magneto-optical technology, applied in the field of laser communication, can solve the problems of large size, inability to meet the requirements of miniaturization and planarization, and achieve the effect of miniaturization and size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below with reference to specific embodiments and accompanying drawings. It should be noted that the present invention is not limited to this embodiment.

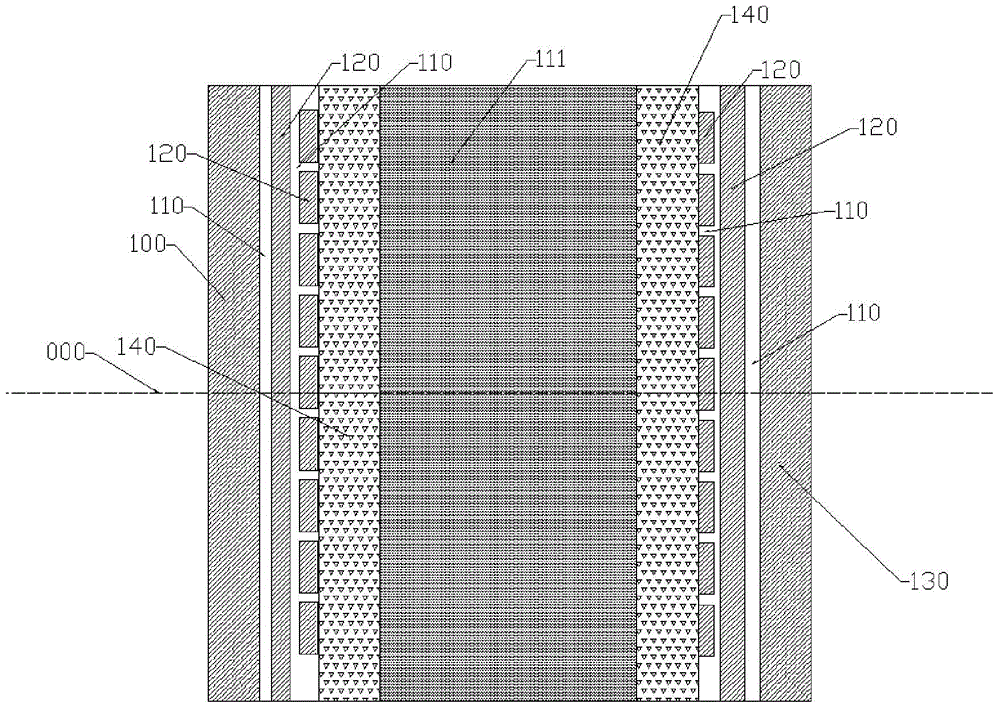

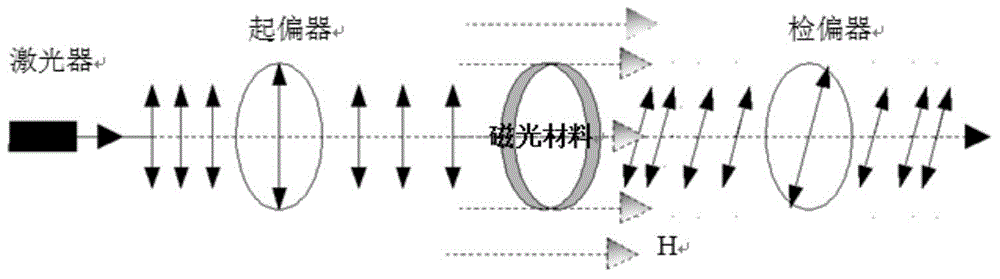

[0018] The planar magneto-optical isolator includes a polarizer 100, a Faraday rotator and an analyzer 130 placed parallel to each other along the light passing direction, wherein the polarizer and the analyzer are both thin-film polarizers, and the polarizer and the analyzer are transparent. The vibration directions form an angle of 45° with each other, and an insulating layer is also provided between the polarizer and the Faraday rotator and between the analyzer and the Faraday rotator; the Faraday rotator consists of a second microstrip line layer, Insulation layer, first microstrip line layer, garnet film, GGG substrate, garnet film, first microstrip line layer, insulating layer, second microstrip line layer, wherein the second microstrip line layer, insulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com