A fireproof transformer

A transformer and refractory technology, applied in the field of transformers, can solve the problems of local fires, safety accidents, magnetic core heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

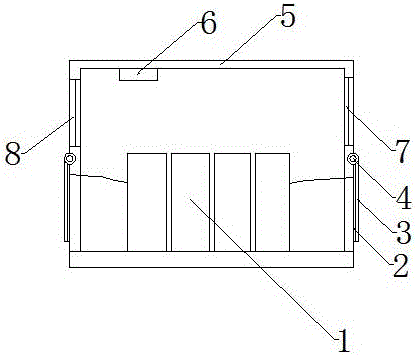

[0017] A fire-proof transformer, including: a coil frame 1 for winding coils, a magnetic core placed in the central through hole of the coil frame 1, a fire-resistant transformer shell 5, vents 8 on both sides of the fire-resistant transformer shell 5, and rotatable and closed vents beside the vent 8 Closure assembly for vent 8, temperature sensor 6 inside refractory transformer housing 5.

[0018] The closure assembly consists of: a rotating part fixed on the refractory transformer casing 5, preferably an electric rotating shaft 4; a closing cover 2 connected to the rotating part, a sealing layer 3 covering the above closing cover 2 and contacting the vent 8 Preferably, the sealing layer 3 is a rubber layer; the material used for the fire-resistant transformer shell 5 is a thermosetting resin-impregnated paper high-voltage laminate.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com