Environment-friendly wood structure building automatic fire fighting device

A technology of building automatic and fire-fighting devices, which is applied in fire rescue and other directions, can solve the problems of inaccessible water flow, lack of automatic and accurate positioning of fire sources, inconvenient use, etc., and achieve the effect of achieving connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

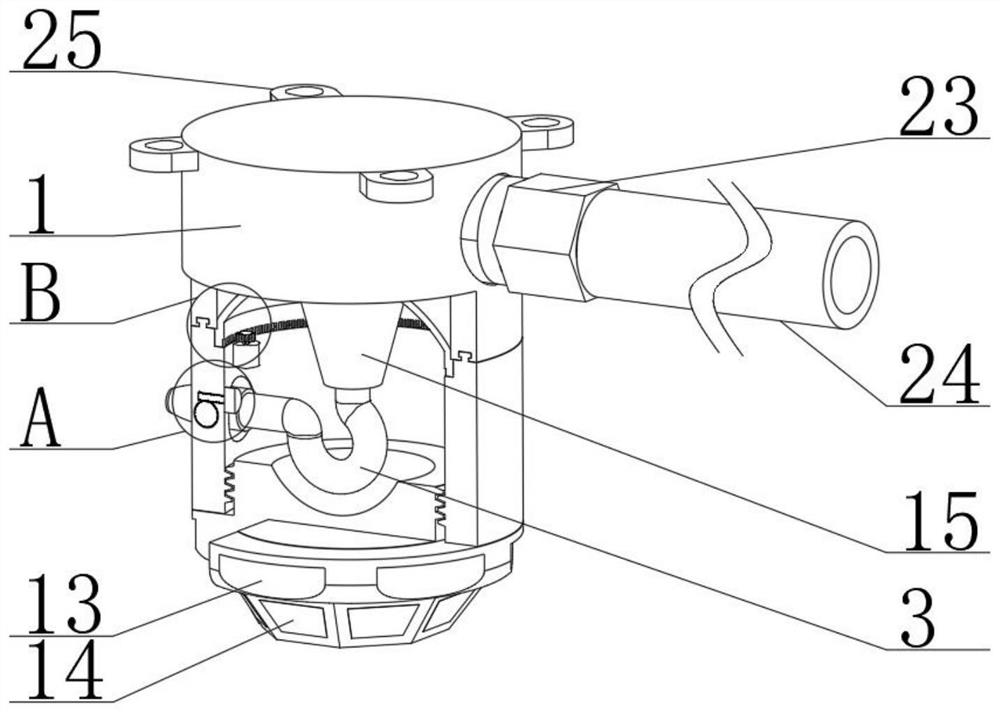

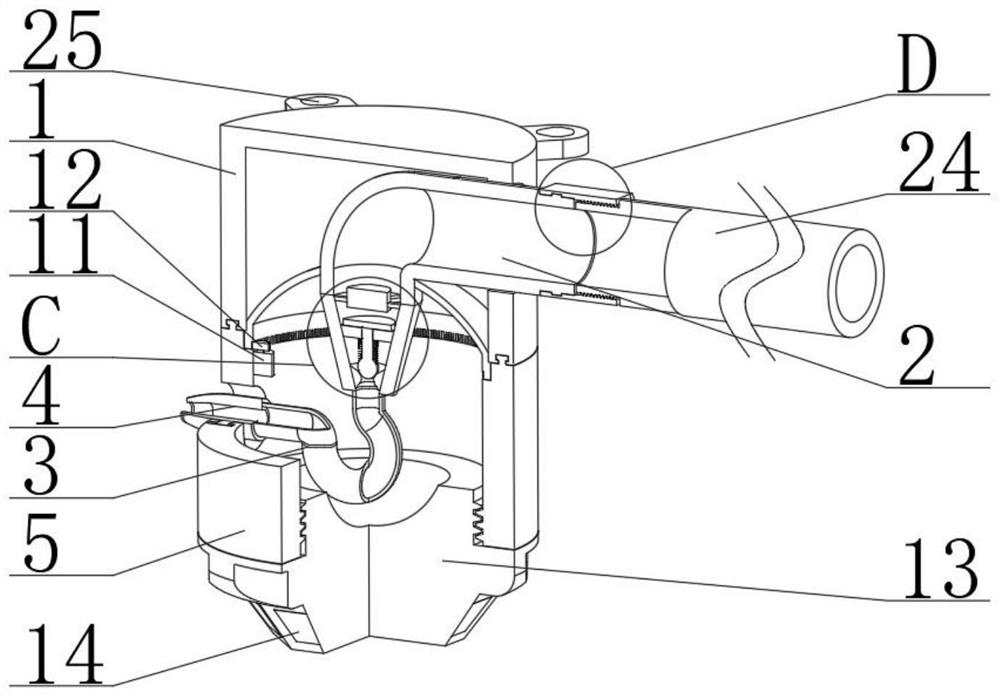

[0031] see figure 2 , 4 And 5, an environment-friendly automatic fire-fighting device for wooden structures, comprising an upper tank body 1, the inside of the upper tank body 1 is fixedly connected with a connecting pipe 2, one end of the connecting pipe 2 is fixedly connected with a pressurized pipe 15, and the pressurized pipe 15 The bottom end of the upper tank body 1 is fixedly connected with a flexible pipe 3, and the pressurized tube 15 is a funnel-shaped pipe with a large opening diameter at the upper end and a smaller opening diameter at the lower end. A through hole is opened, the inside of the through hole is movably connected with the nozzle 4, the other end of the hose 3 is fixedly connected with the nozzle 4, the inside of the lower tank 5 is movably connected with the first gear 6, one side of the nozzle 4 is connected with the first gear 6 is fixedly connected, the inner side of the lower tank body 5 is fixedly installed with a first motor 7, and one end of t...

Embodiment 2

[0034] see image 3 and 6 , this embodiment is further optimized on the basis of Embodiment 1, specifically, a first support frame 16 is fixedly connected to the inside of the connecting pipe 2, and an electromagnet 17 is fixedly connected to one side of the first support frame 16.

[0035] Specifically, the inner side of the pressurizing tube 15 is fixedly connected with a sealing ring 18 and a second support frame 19, the inside of the second support frame 19 is penetrated and movably connected with a sealing column 20, and the top end of the sealing column 20 is fixedly connected with an iron plate 21, Iron plate 21 is matched with electromagnet 17.

[0036] Specifically, a spring 22 is fixedly connected to one side of the sealing column 20 , and a second support frame 19 is fixedly connected to the top end of the spring 22 .

[0037] In this embodiment, the electromagnet 17 can be fixed by the first support frame 16, the sealing column 20 can be supported by the second s...

Embodiment 3

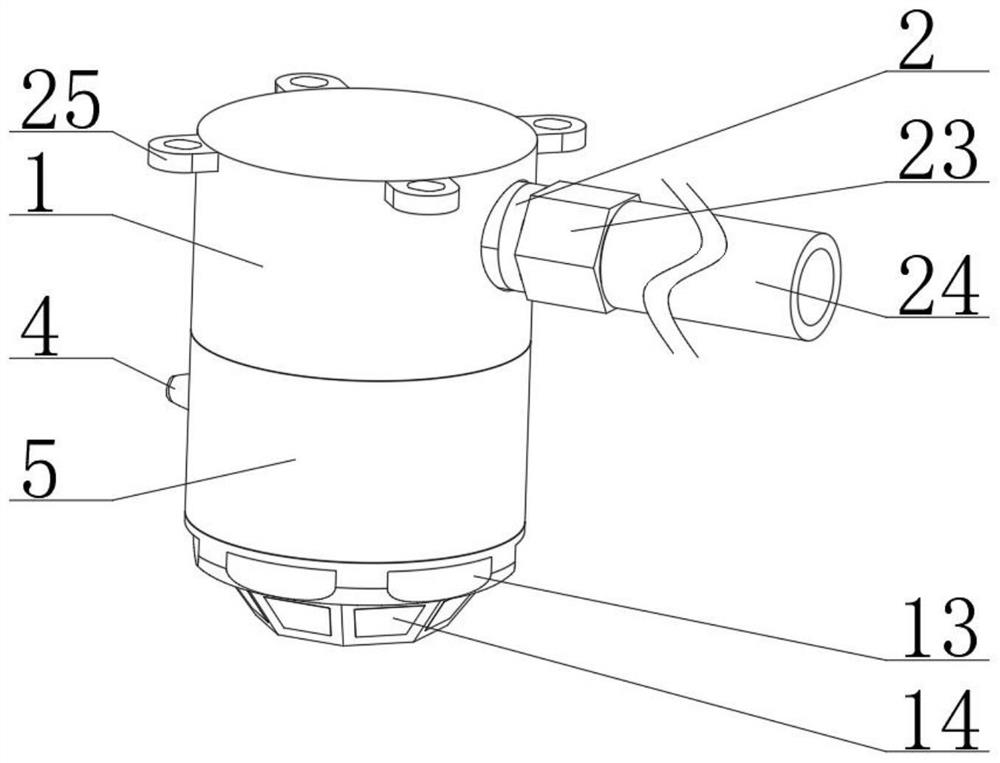

[0039] see figure 1 and 7 , the present embodiment is optimized as follows on the basis of example 1 or example 2, specifically, the upper end side of the connecting pipe 2 is movably connected with a connecting ring 23, and the inner side of the connecting ring 23 is movably connected with a water supply pipe 24, and the connecting ring 23 is compatible with water supply pipe 24.

[0040] Specifically, a plurality of mounting plates 25 are fixedly connected to the upper surface of the upper tank body 1 , and the plurality of mounting plates 25 are distributed in an annular array.

[0041]In this embodiment, the connection between the connecting pipe 2 and the water supply pipe 24 can be realized through the matching of the connecting ring 23 and the water supply pipe 24, and then the communication of the external water source can be realized. Install.

[0042] To sum up: the present invention can detect whether there is high temperature in multiple directions in the area b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com