Mobile Turning Mechanism for Assembling Vacuum Circuit Breakers

A vacuum circuit breaker and flipping mechanism technology, which is applied in the manufacture of circuits, emergency protection devices, emergency protection devices, etc., can solve the problems affecting the safety and convenience of high-voltage switchgear, solid-sealed poles, and insulated sleeves that cannot be used. Epoxy resin is easy to be destroyed and other problems, so as to achieve the effect of safe and reliable installation and operation, avoid manual handling and turning, and save labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

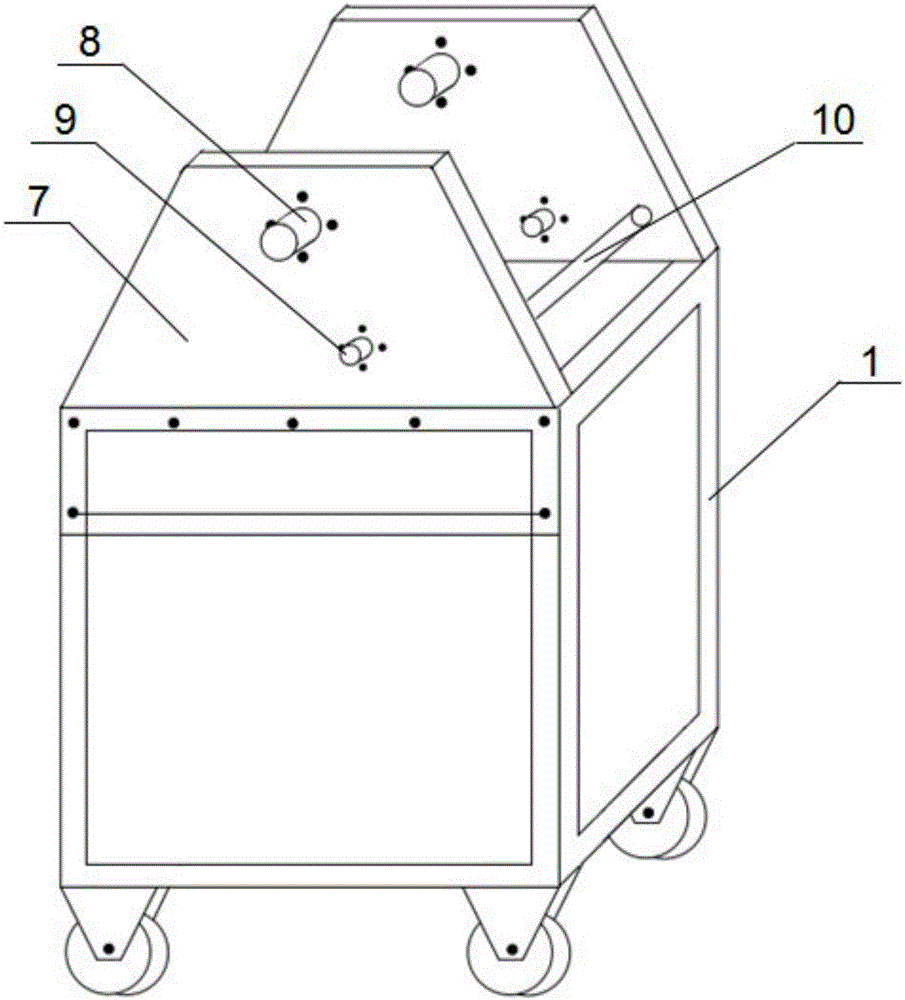

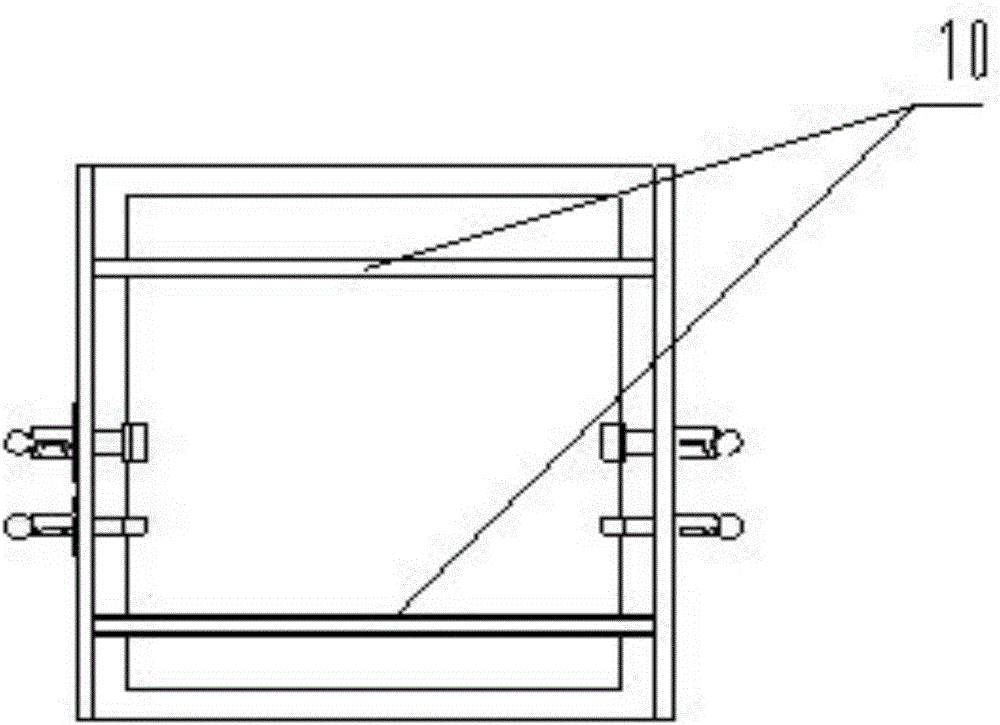

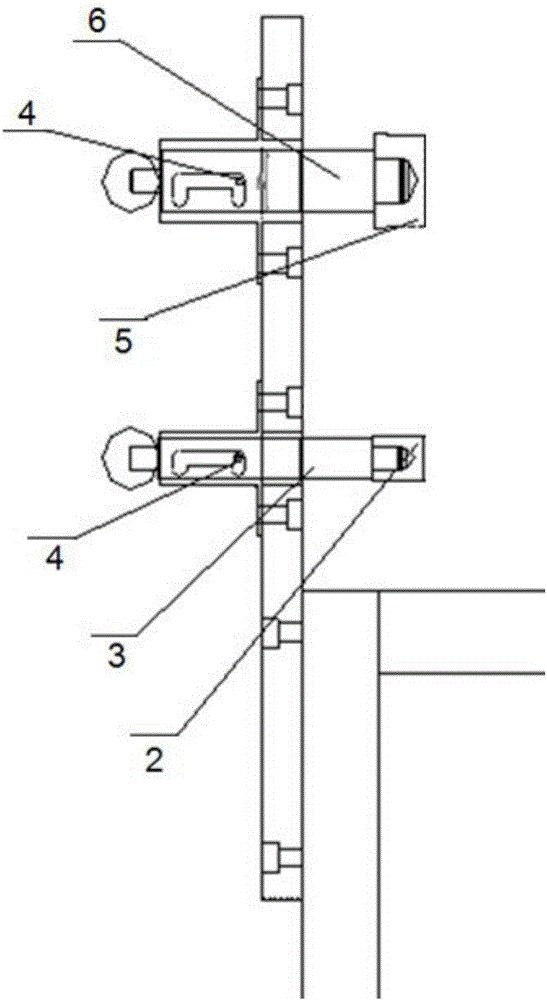

[0028] As shown in the figure, the mobile overturn mechanism for assembling vacuum circuit breakers is characterized in that it includes an aluminum alloy four-wheel vehicle 1, a fixed plate 7, a fixed limit shaft 10, and an overturn system. The overturn system includes a movable pin 3, a center Pin 6, center pin jacket 8 and movable pin jacket 9;

[0029] The fixed plate 7 is installed on the top side of the aluminum alloy four-wheel vehicle 1, and the fixed plate 7 is fixedly connected by a fixed limit shaft 10, and a turning system is installed on the fixed plate 7; the central pin 6 is installed on the fixed plate. In the middle of the upper end of the plate 7, the outer side of the center pin 6 is wrapped with a center pin jacket 8; the movable pin 3 is installed on the lower side of the fixed plate 7, and the outer side of the movable pin 3 is wrapped with a movable pin jacket 9.

[0030] The bottom end of described aluminum alloy four-wheel vehicle 1 is equipped with fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com