Rare earth element ring magnet with means for receiving foreign particles

A technology of ring magnets and utensils, applied in the direction of magnets, magnetic objects, electrical components, etc., can solve problems such as friction, noise, and deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

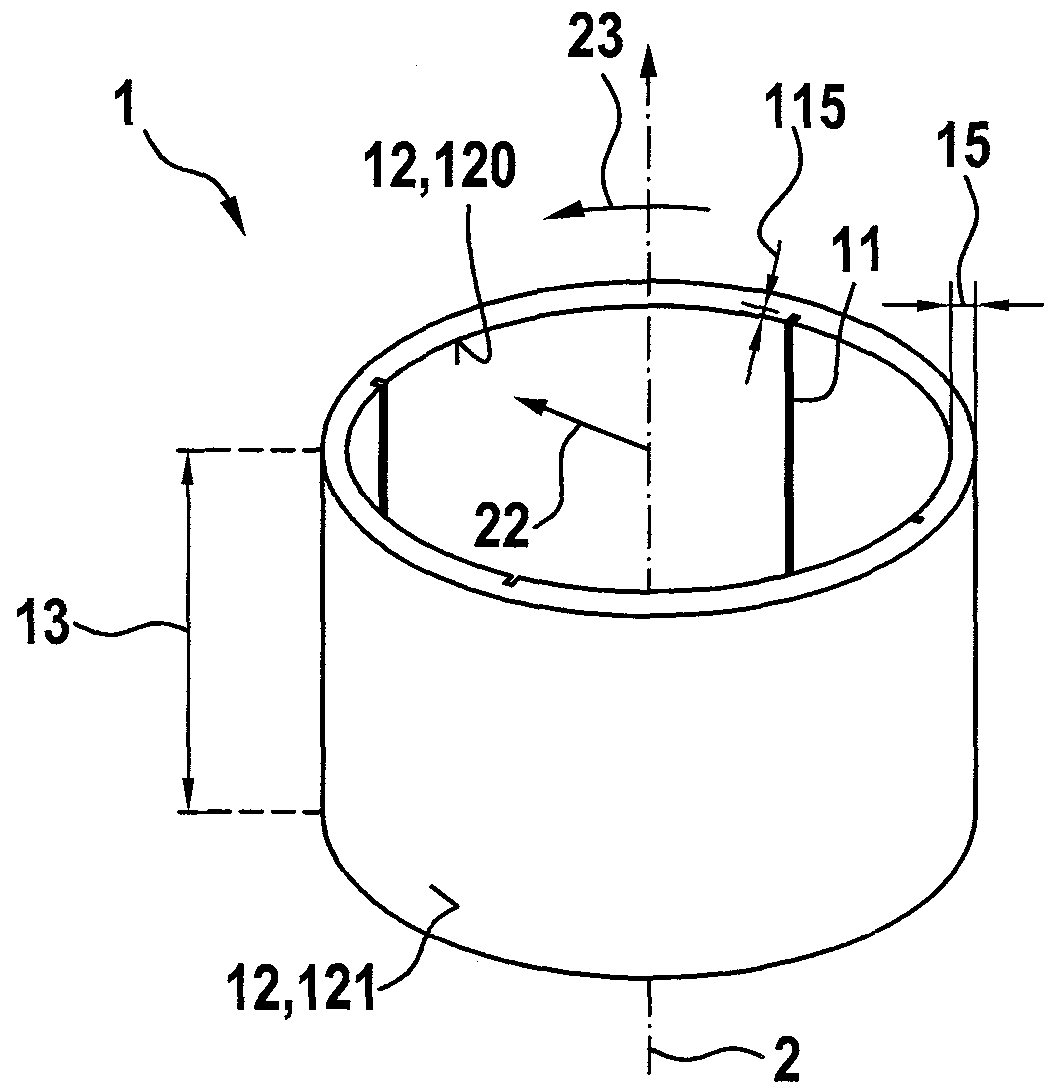

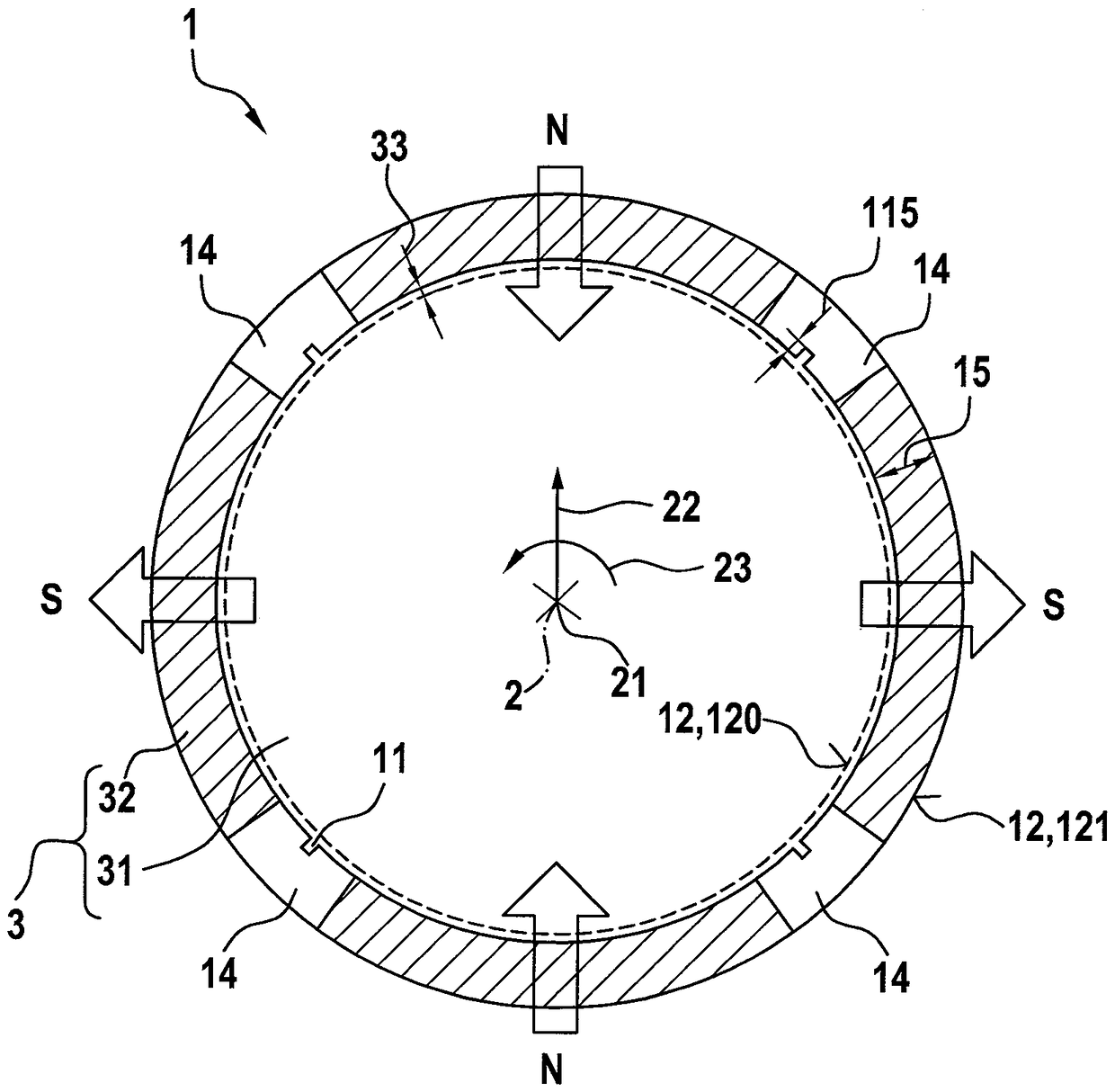

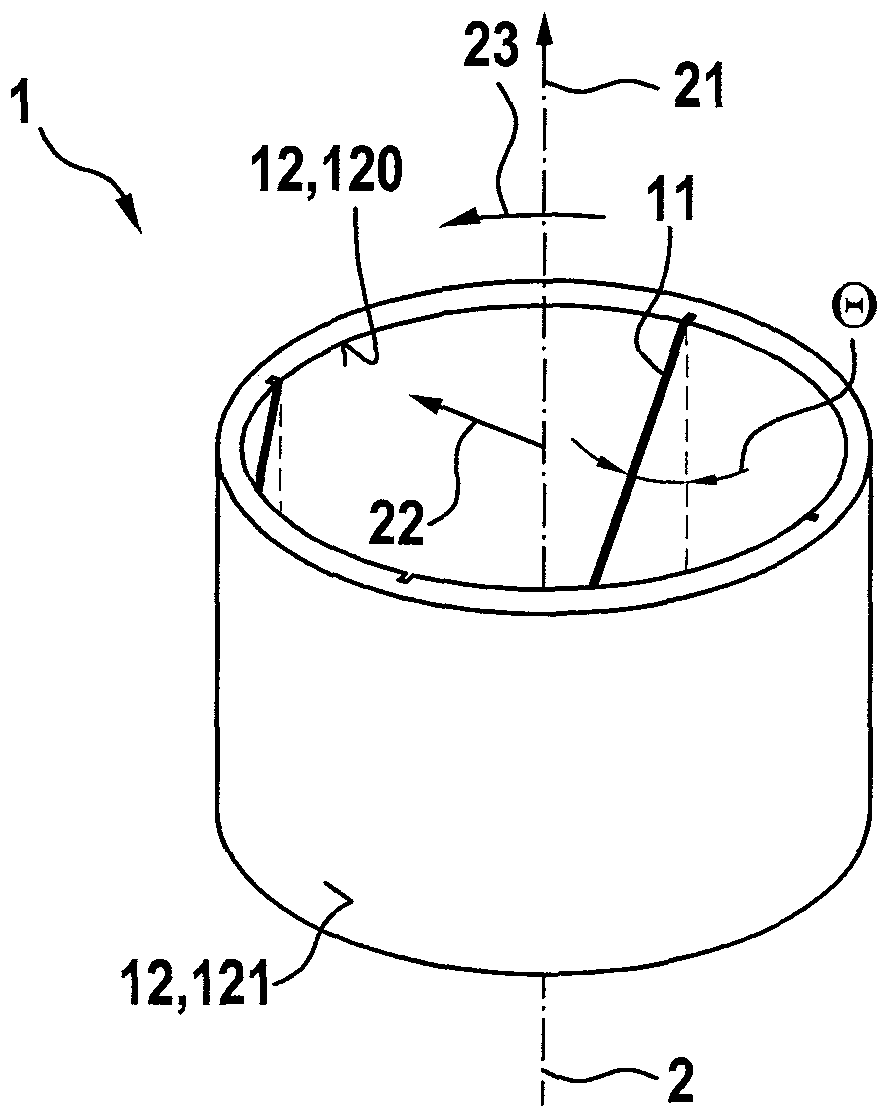

[0021] figure 1 The ring magnet 1 is hollow-cylindrical and extends concentrically around an axis 2 in an axial direction 21 . It has four magnetic poles N, S, between which a pole transition region 14 is formed in each case. The magnetic poles N, S are alternately magnetized opposite to each other, so that a magnetic north pole N alternates with a magnetic south pole S. They are arranged at equal distances from one another, so that the pole transition regions 14 are also equally spaced from one another.

[0022] The ring magnet 1 has a surface 12 defining it, wherein the surface 12 facing away from the axis is hereinafter referred to as the outer surface 121 and the surface 12 facing the axis is hereinafter referred to as the inner surface 120 .

[0023] Receptacles 11 are formed on inner surface 120 in pole transition region 14 , and are provided for receiving foreign particles (not shown). The device 11 thus forms a sink for foreign particles. Here, too, they are formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com