Plastic ejection mechanism of grain forming machine

A technology of ejection mechanism and molding machine, which is applied in the direction of weapon types, offensive equipment, pyrotechnics, etc., and can solve the problems of easy damage and waste of manpower in the process of pulling out the powder column

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

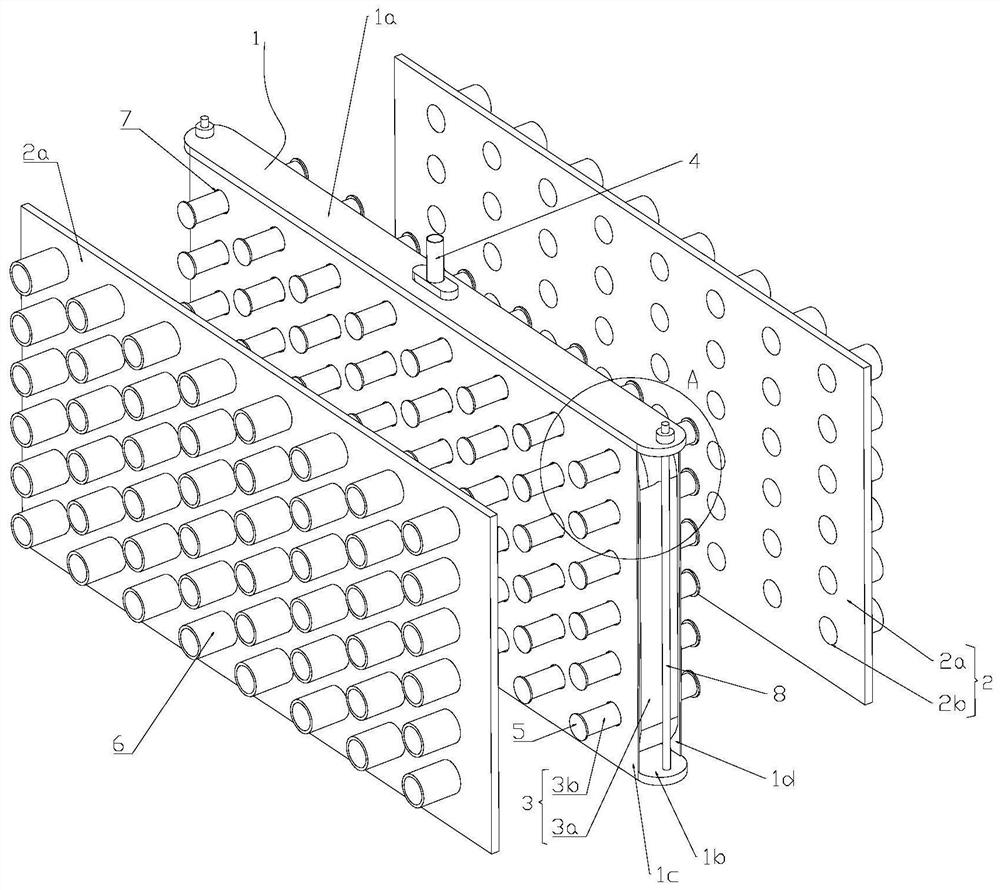

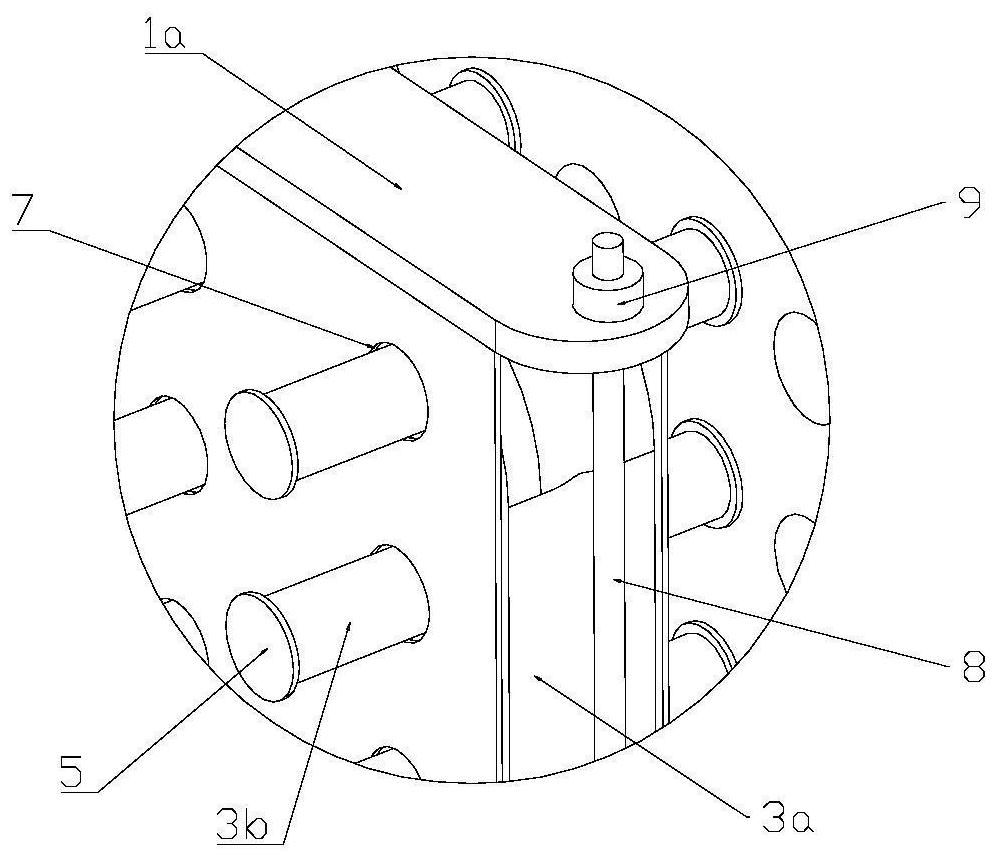

[0018] see figure 1 , figure 2 As shown, the present invention provides a shaping and ejecting mechanism of a grain forming machine, comprising an airbag frame 1 and a shaping plate 2, an inflatable airbag 3 is placed in the airbag frame 1, and a communicating airbag is installed on the airbag frame 1 The air delivery tube 4 of 3, the air delivery tube 4 is externally connected to the air pump, the air bag 3 includes a main air bag 3a and a plurality of branch air bags 3b communicated with the main air bag 3a, the end of the branch air bag 3b is provided with a top sheet 5; the shaping plate 2 includes a shaping The splint 2a, the shaping splint 2a is provided with a plurality of limit holes 2b for the extension of the airbag 3b, the limit hole 2b is coaxially provided with a shaping tube 6, and the top sheet 5 is slidably installed on the shaping tube 6 Inside.

[0019] Specifically, the shaping splint 2a is used to shape the pyrotechnic powder into a powder column. When i...

Embodiment 2

[0022] In this embodiment, one of the optimized designs is made on the basis of the above-mentioned embodiments. The airbag frame 1 includes a top plate 1a and a bottom plate 1b which are opposite and spaced apart, and a front side plate 1c and a front side plate 1c are arranged opposite and spaced between the top plate 1a and the bottom plate 1b. The rear side plate 1d, the air bag 3 is placed in the gap between the top plate 1a, the bottom plate 1b, the front side plate 1c and the rear side plate 1d, the air pipe 4 is installed on the top plate 1a, and both the front side plate 1c and the rear side plate 1d A through hole 7 for extending the branch air bag 3b is provided, and the diameter of the top sheet 5 is larger than the diameter of the through hole 7 . The airbag frame 1 forms a square frame, which can withstand the extrusion of the shaping plate 2 and protect the inner airbag 3 .

[0023] As another improvement, the end of the top plate 1a and the end of the bottom pl...

Embodiment 3

[0025] In this embodiment, one of the optimized designs is made on the basis of the above-mentioned embodiments. There are two plastic splints 2a, one of which is set close to the front side plate 1c, and the other plastic splint 2a is close to the rear Side panel 1d set. Wherein, by arranging the shaping plate 2 in two directions, the grain column can be processed in two directions at the same time, and the processing efficiency can be fully improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com