Temperature adjusting method of heat energy recovery type injection mold

An injection mold and temperature adjustment technology, applied in the field of injection molds, can solve the problems affecting the molding quality of products, and the mold temperature cannot be accurately controlled, so as to avoid the waste of water resources and thermal energy, improve the molding quality, and achieve high adjustment accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

[0012] A method for regulating the temperature of a heat recovery type injection mold, comprising the following steps:

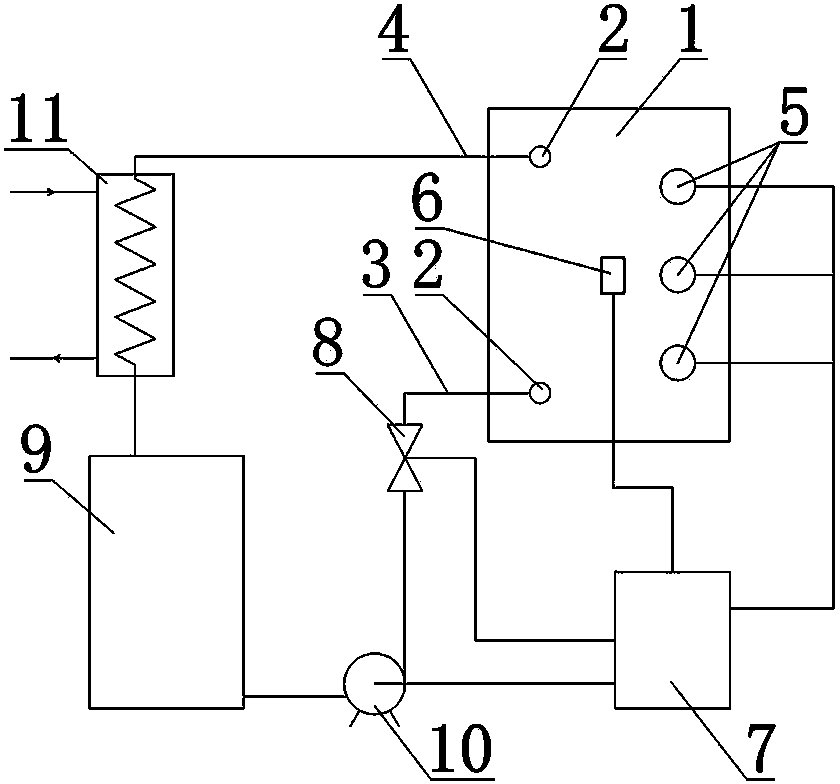

[0013] S1. Set the cooling water channel 2 and the heater installation hole in the injection mold. Preferably, the cooling water channel 2 is arranged in a serpentine or annular shape, and an electric heater 5 is installed in the heater installation hole. One of the cooling water channels 2 The port is connected to the water inlet pipe 3, the other port of the cooling water channel 2 is connected to the water outlet pipe 4, the water outlet of the cooling water storage tank 9 is connected to the water inlet pipe 3 through the delivery pump 10, and the solenoid valve 8 is installed on the water inlet pipe 3, and the outlet The water pipe 4 is sequentially connected to the water inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com