pcb board placement rack

A technology for PCB boards and racks, applied in external frames, containers to prevent mechanical damage, packaging of vulnerable items, etc., can solve the problems that the wires are easily damaged, affect the quality of PCB boards, and trouble manufacturers, and achieve good application prospects. Fully protect the PCB board and increase the effect of space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

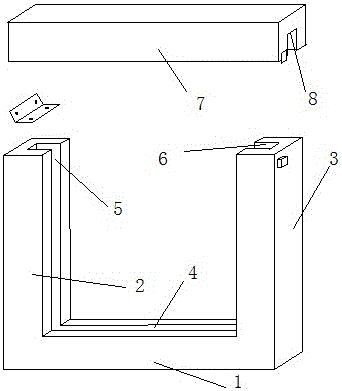

[0016] Such as figure 1 As shown, the PCB board placement frame includes a first stop bar 1 placed horizontally, and two ends of the first stop bar 1 are provided with a symmetrically arranged second stop bar 2 and a third stop bar perpendicular to the first stop bar 1 Rod 3, the first blocking rod 1, the second blocking rod 2 and the third blocking rod 3 constitute the basic frame of the placement rack. During manufacture, the first blocking rod 1, the second blocking rod 2 and the third blocking rod 3 are integrally formed , or the two ends of the first blocking rod 2 are respectively connected with the second blocking rod 2 and the third blocking rod 3 through inserting blocks and grooves, no matter which method can realize the basic frame of the placement rack. In detail, the first blocking rod 1 is provided with a first through slot 4 along the length direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com