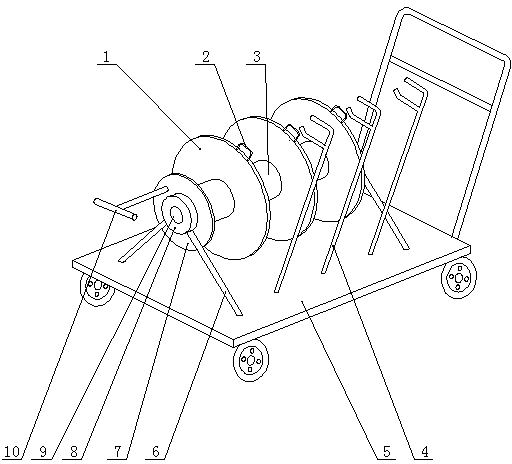

750kv ground wire roller type wire coil

A roller type, grounding wire technology, applied in the field of winding devices, can solve the problems of high physical exertion, inconvenient movement, and delayed operation time of the staff, and shorten the time, placement and removal of the grounding wire and the grounding wire. Convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0011] Example: such as figure 1 As shown, the 750kV grounding wire roller type reel includes a base 5, a running wheel is installed under the base 5, and a push handle is installed at the rear end of the base 5. A symmetrical bearing frame 6 is installed at the front and back of the base 5, bearings 8 are installed on the top of the two bearing frames 6, and a rotating shaft 9 is installed between the two bearings 8, and a reel 3 is fixedly sleeved on the rotating shaft 9. On the reel 3, the The turntable 7 and the reel 1 are installed equidistantly from front to back, the grounding fixed end 2 is installed on the circumferential surface of the reel 1, and the conductor end support 4 is fixed on the base 5 on the side of the reel 1 . There are at least three reels 1, which together with the turntable 7 surround at least three reel spaces.

[0012] The grounding fixed end 2 is a cavity frame, which is used for tying the grounding end of the grounding wire thereon.

[0013] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com