A safe automatic steel loading positioning device and method for heating furnace

A positioning method and heating furnace technology, applied in the field of steel rolling, can solve problems such as hidden safety hazards, and achieve the effects of reducing losses, reducing maintenance costs, and avoiding slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It is easy to understand that, according to the technical solution of the present invention, without changing the essential spirit of the present invention, a person of ordinary skill in the art can propose multiple structural modes and manufacturing methods of the present invention. Therefore, the following specific embodiments and drawings are only specific descriptions of the technical solutions of the present invention, and should not be regarded as all of the present invention or as limitations or limitations of the technical solutions of the present invention.

[0030] The present invention will be further described in detail below in conjunction with the embodiments and drawings.

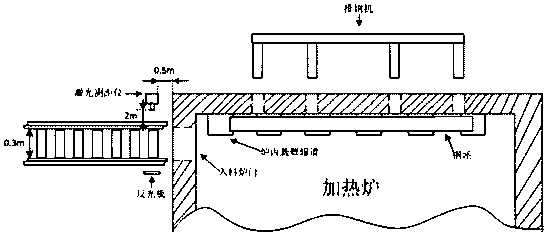

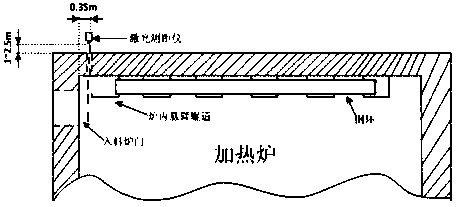

[0031] Such as figure 1 As shown, the automatic steel loading positioning device of the safety heating furnace includes: a laser distance meter, a furnace entering roller table and a charging cantilever roller table;

[0032] The laser rangefinder is used to reliably position the billet into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com