A device and method for direct preparation of aluminum alloy by molten salt electrolysis-casting

A technology of molten salt electrolysis and molten salt electrolyte, which is applied in the field of electrolytic metallurgy, can solve problems such as no discovery, difficulty in producing aluminum-lithium alloys that meet the requirements, and increased cost of aluminum-lithium alloys, so as to achieve convenient operation of the device, good application prospects, Effect of elemental segregation reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

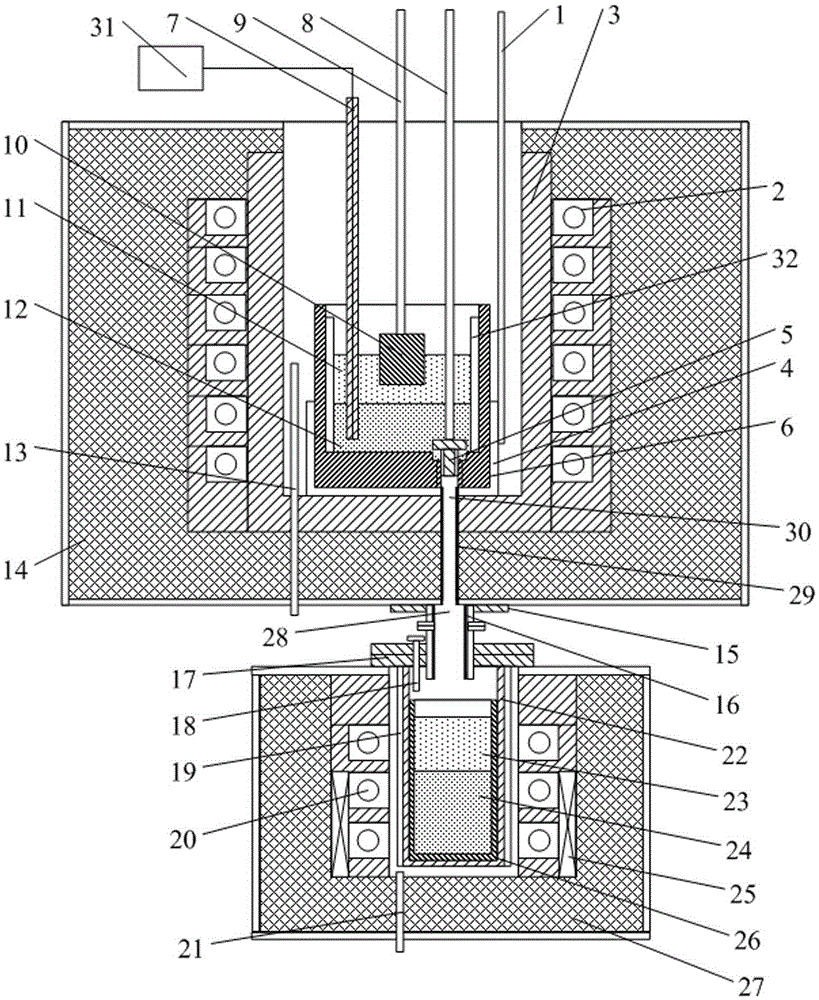

[0048] A device for directly preparing aluminum alloys by molten salt electrolysis-casting such as figure 1 as shown,

[0049] Consists of the electrolyzer system and the casting system below it;

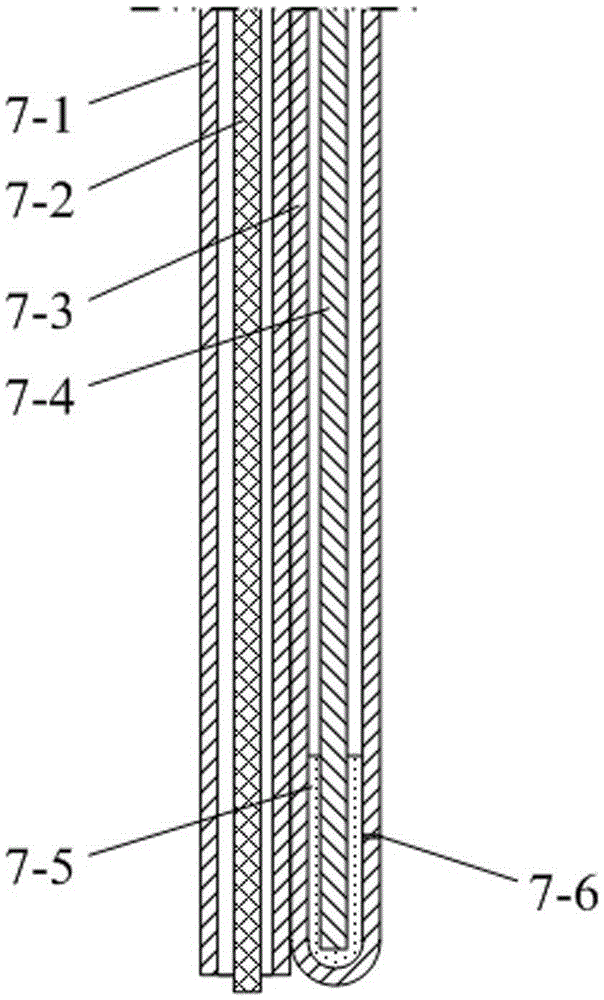

[0050] The electrolytic cell system includes an electrolytic heating furnace 14, an electrolytic iron crucible 4, a graphite crucible 6, a graphite anode 10 and a potential test probe 7; the electrolytic iron crucible 4 is located in the electrolytic heating furnace, and the electrolytic iron crucible 4 is set outside the graphite crucible 6. 6 The side wall is provided with a corundum insulating liner 32; the graphite anode 10 and the potential test probe 7 are inserted into the graphite crucible 6; the bottom of the graphite crucible 6 is provided with a bottom opening channel 30 and a bottom opening cock 5, and the bottom opening channel 30 passes through the electrolytic Iron crucible 4 is communicated with electrolytic heating furnace 14 bottoms;

[0051] The casting system i...

Embodiment 2

[0080] The device for directly preparing aluminum alloy by molten salt electrolysis-casting is the same as in Example 1;

[0081] The method of directly preparing aluminum alloy by molten salt electrolysis-casting is the same as that of Example 1, the difference is that:

[0082] Preparation of the aluminum-lithium alloy whose grade is 2397: prepare other metals except lithium according to the ratio of each element in the 2397 aluminum-lithium alloy, as the cathode master alloy;

[0083] Add the cathode master alloy and the molten salt electrolyte into the graphite crucible, heat the cathode master alloy and the molten salt electrolyte through the electrolytic heating furnace until they are completely melted, and then continue to heat to 30°C higher than the full melting temperature;

[0084] The amount of the cathode master alloy added is twice the weight of the cathode master alloy according to the molten salt electrolyte and electrolytic raw materials;

[0085] The addition ...

Embodiment 3

[0092] The device for directly preparing aluminum alloy by molten salt electrolysis-casting is the same as in Example 1;

[0093] The method of directly preparing aluminum alloy by molten salt electrolysis-casting is the same as that of Example 1, the difference is that:

[0094] Preparation of the aluminum-lithium alloy whose grade is 2197: prepare other metals except lithium according to the ratio of each element in the 2197 aluminum-lithium alloy, as the cathode master alloy;

[0095] Add the cathode master alloy and molten salt electrolyte into the graphite crucible, heat the cathode master alloy and molten salt electrolyte through the electrolytic heating furnace until they are completely melted, and then continue to heat to 40°C higher than the full melting temperature;

[0096] The amount of the cathode master alloy added is 1.8 times the weight of the cathode master alloy according to the molten salt electrolyte and electrolytic raw materials;

[0097] The amount of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com