Technology of rapidly constructing cofferdam by large mud-filled bags combined with sand-filled bags on soft soil foundation

A technology of soft soil foundation and sand bag, applied in water filling, embankment, coastline protection, etc., can solve the problems of restricting the construction progress of the fence, and achieve the effect of reducing construction cost, saving resources and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

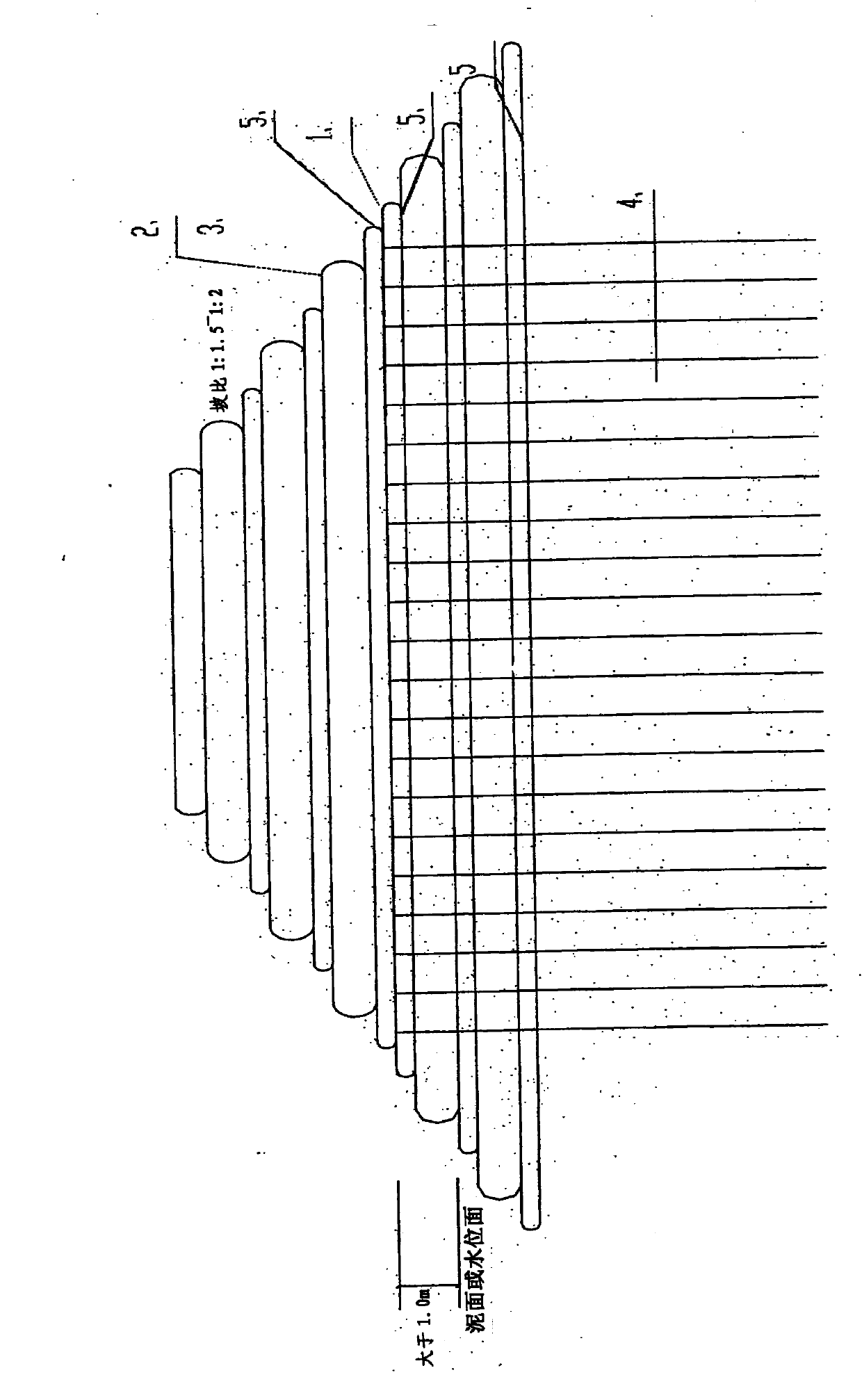

[0018] see figure 1 , a large-scale mud-filled bag combined with sand-filled bag to quickly build an enclosure technology on a soft soil foundation. Its implementation plan: 1. Laying geotechnical soft rows directly on the original mud surface. 2. Carry out the construction of the first layer of large sand-filled bags, with a thickness of 50cm to 80cm3, and the construction of the second layer of mud-filled bags, with a thickness of 40cm to 100cm, which can be selected locally. 4. Sand blowing is carried out within 2m of the outer edge of the mud-filled bag, the purpose is to make the bag body quickly form strength and facilitate the construction of the upper part. 5. Carry out the third layer of sand-filled bag construction, and the thickness of the sand bag body in the middle layer can be controlled within 30cm-80cm. 6. Carry out cyclical construction of blow-filled mud bags and blow-filled sand bags, and the top layer is sand-filled bags. 7. If there is a requirement for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com