Diesel pile hammer

A technology of piling hammer, diesel oil, applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problem of undesired swinging in

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

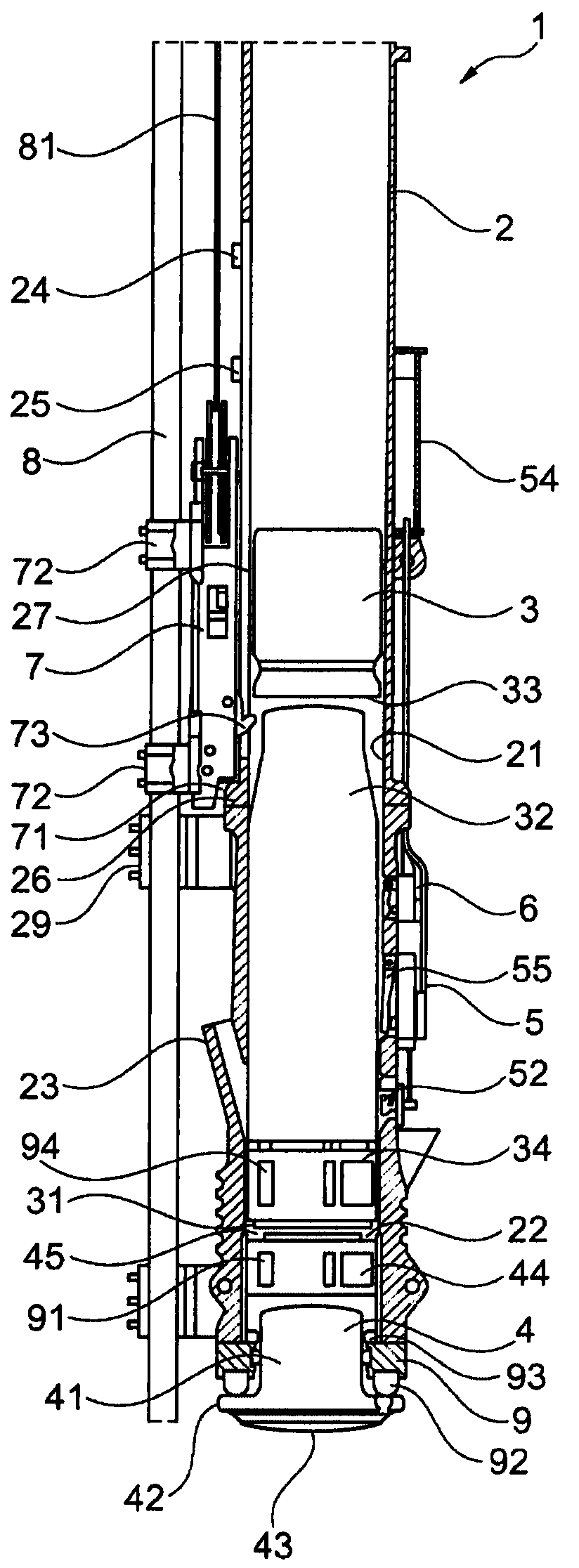

[0022] The piling device chosen as an example comprises a diesel piling hammer with a cylinder 2 open on both sides, which can often have a length of 5 to 10 meters and a diameter of 0.2 to 1 meter. A piston 3 is displaceably arranged in the cylinder 2 . A hammer 4 coaxial therewith engages displaceably in the open lower end of the cylinder 2 . Fastened to the lower end of the cylinder 2 is an annular bearing unit 9 , in which the central rod section 41 of the striker 4 is guided sealingly and displaceably. The inner diameter of the cylinder 2 is reduced by the outer diameter.

[0023] On the lower end of the rod section 41 is formed an impact plate 42 below the cylinder 2 , whose outwardly directed lower convex boundary surface 43 is in contact with the piling object to be driven during operation. The upper end works together.

[0024] Formed on the upper end of the rod section 41 of the hammer 4 is a piston section 44 with a plurality of circumferential, axially spaced-ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com