diesel pile hammer

A piling hammer and diesel technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problem of undesired pendulum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

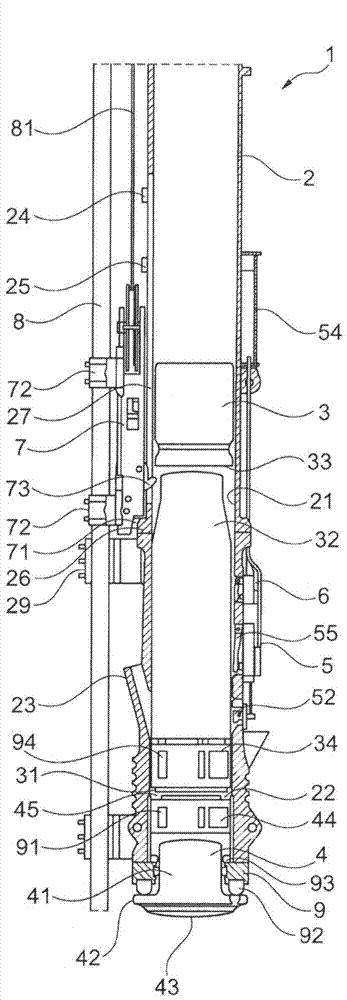

[0022] The piling device chosen as an example comprises a diesel piling hammer with a cylinder 2 open on both sides, which can often have a length of 5 to 10 meters and a diameter of 0.2 to 1 meter. A piston 3 is movably arranged in the cylinder 2 . A coaxial striker 4 is movably inserted into the open lower end of the cylinder 2 . Fastened to the lower end of the cylinder 2 is an annular bearing unit 9 in which a central rod section 41 of the striker 4 is guided in a sealing and displaceable manner, which rod section has a relative The inner diameter of the cylinder 2 is reduced to the outer diameter.

[0023] On the lower end of the rod section 41 is formed a strike plate 42 below the cylinder 2 , the lower, outwardly directed lower boundary surface 43 of the strike plate, in operation, is in contact with the pile driver to be driven in. The upper ends of the joints work together.

[0024] At the upper end of the rod section 41 of the striker 4 , a piston section 44 is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com