Scroll compressor differential pressure control during compressor shutdown transitions

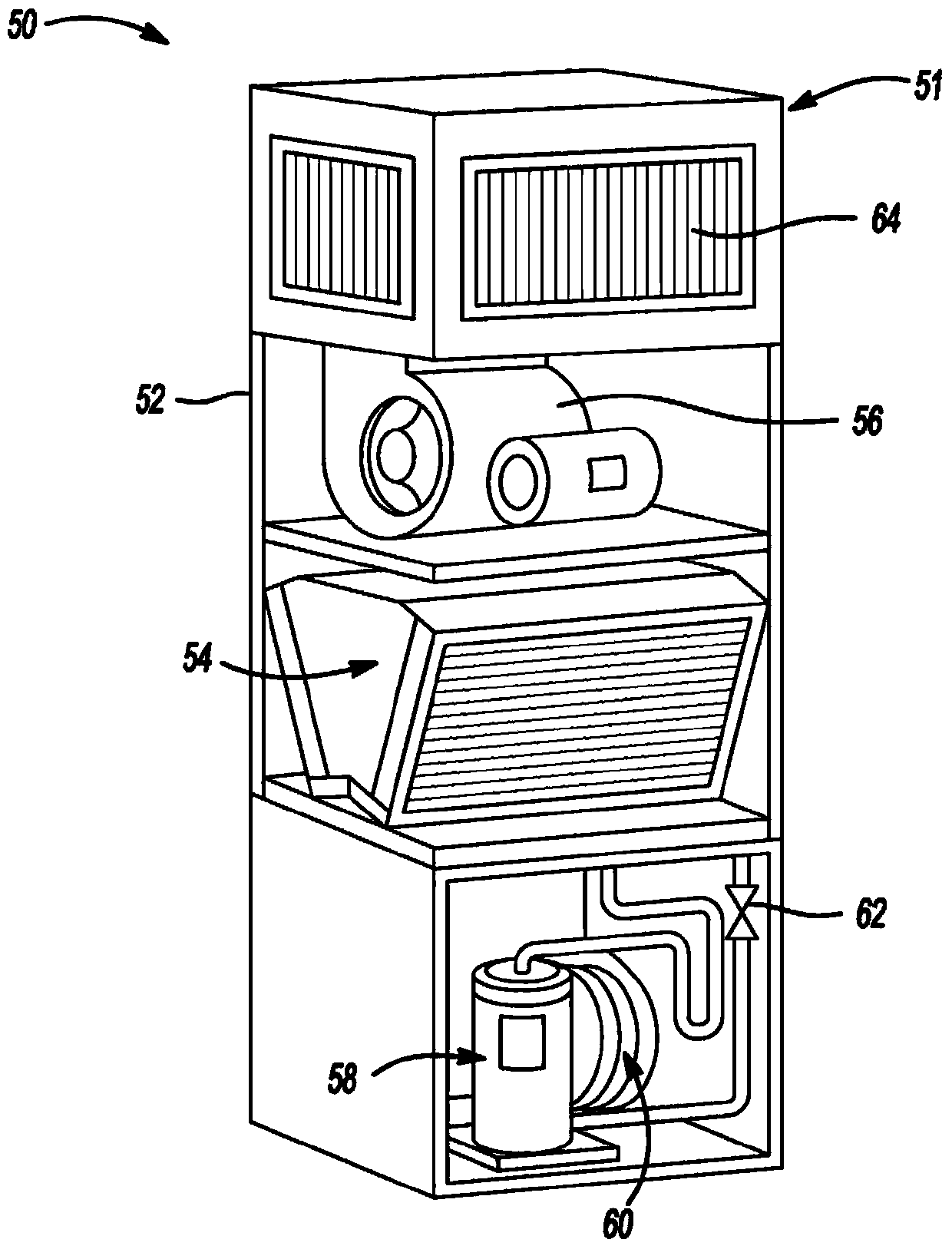

A compressor, scroll technology, applied in the field of pressure control systems, which can solve problems such as reducing the ability to move steam, reducing cooling capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Example embodiments will now be described more fully with reference to the accompanying drawings.

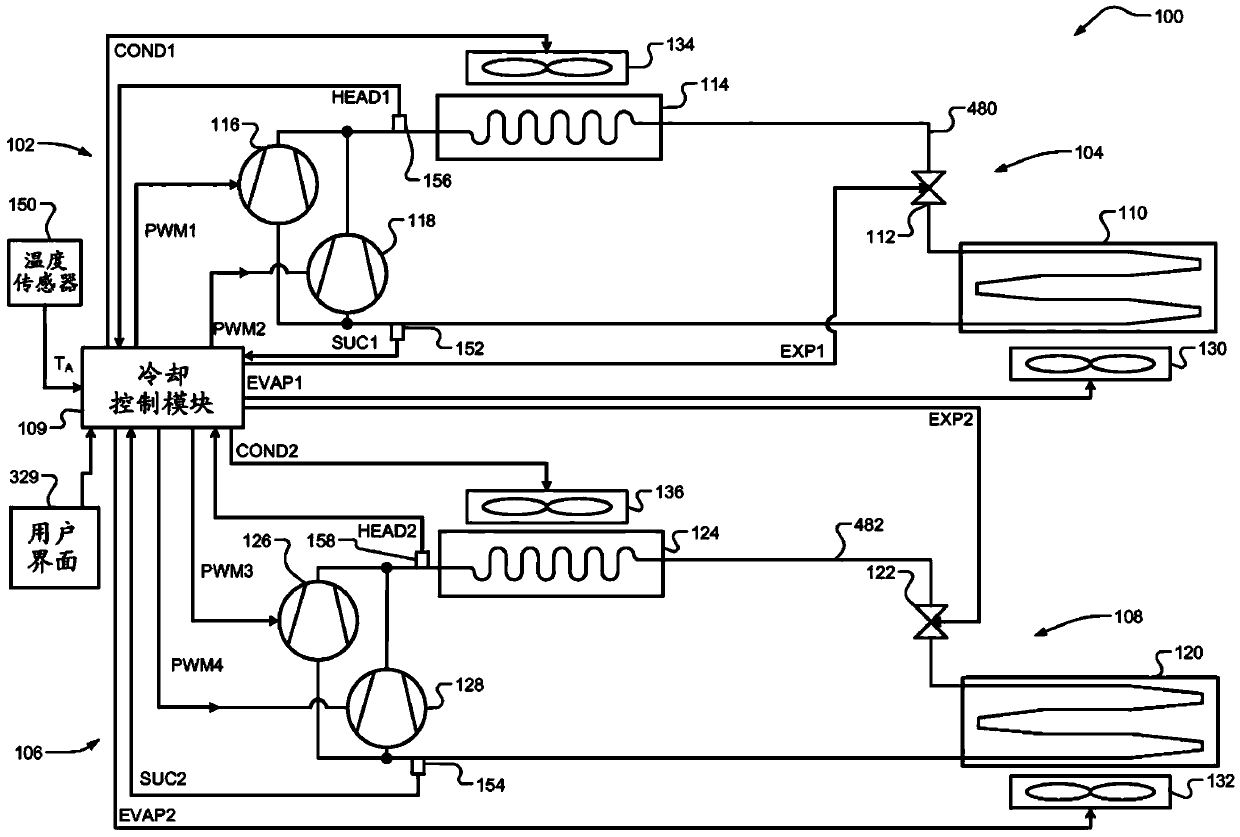

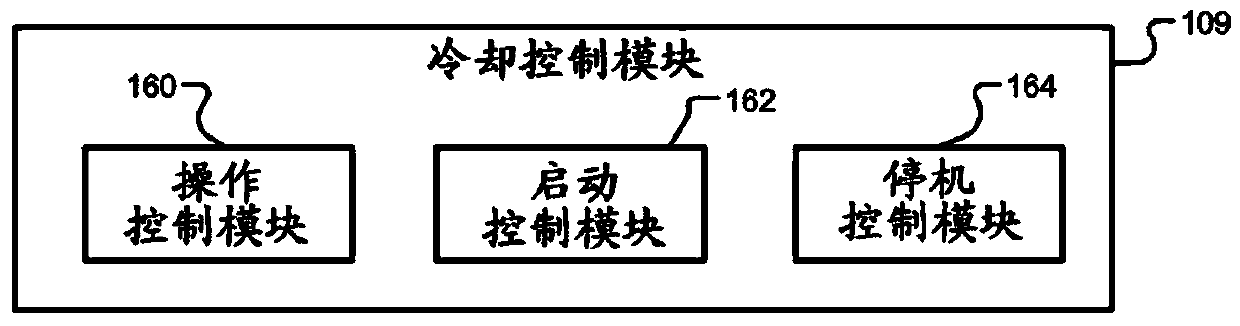

[0048] The embodiments described below prevent uncontrolled unloading of the scroll compressor. Embodiments include techniques to ensure that each pressure ratio or pressure difference of each scroll compressor is maintained at or above a predetermined level. Pressure ratio refers to the ratio between input pressure and output pressure of one or more compressors. Pressure differential refers to the difference between the input pressure and output pressure of one or more compressors. The predetermined level may be greater than or equal to a level at which an associated scroll compressor is uncontrolled unloaded. Although the following techniques are described primarily in terms of pressure differentials, pressure ratios can be determined and used.

[0049] exist Figures 2 to 11 A technique commonly used in the operation of a tandem scroll compressor is shown in . exi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com