Device and method for detecting broken bean defects on checker plate of hot-rolled Bepsi-Tai surface inspection system

A technology of surface inspection and detection method, applied in the directions of optical testing flaws/defects, image data processing, instruments, etc., can solve problems such as failure to guarantee 100% detection of cracked bean defects in checkered boards, system defect overflow, and broken beans of checkered boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

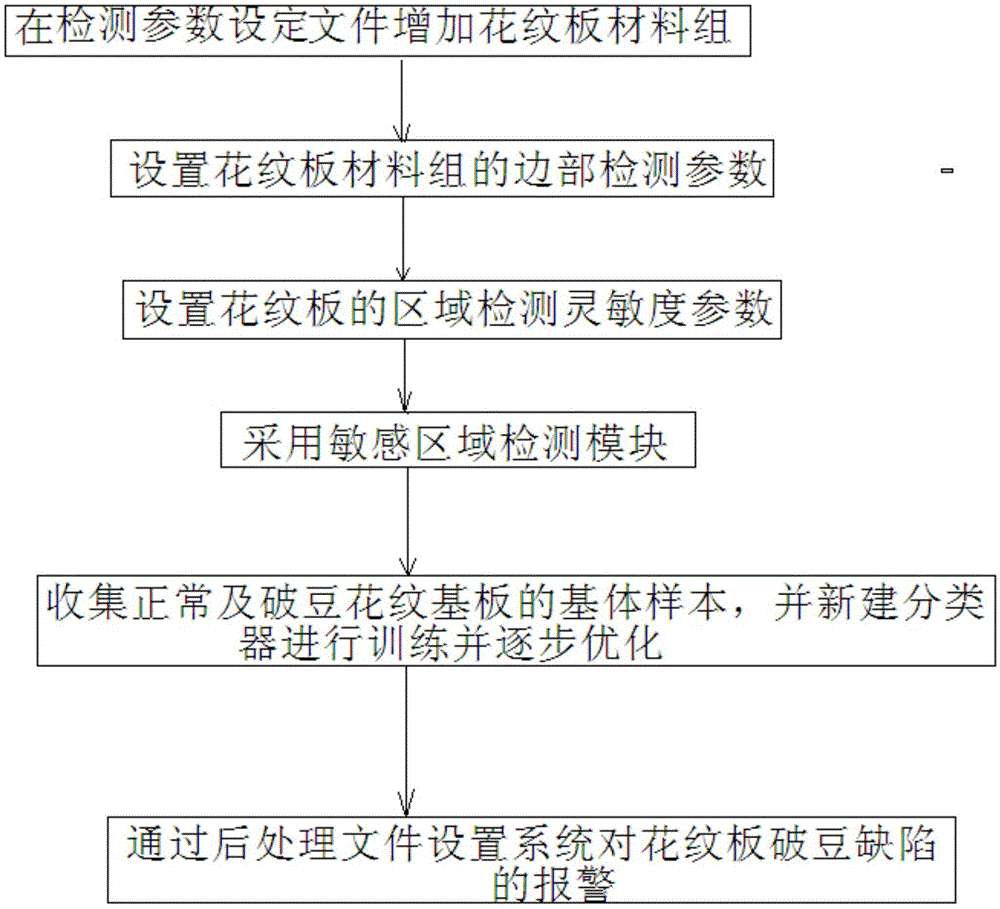

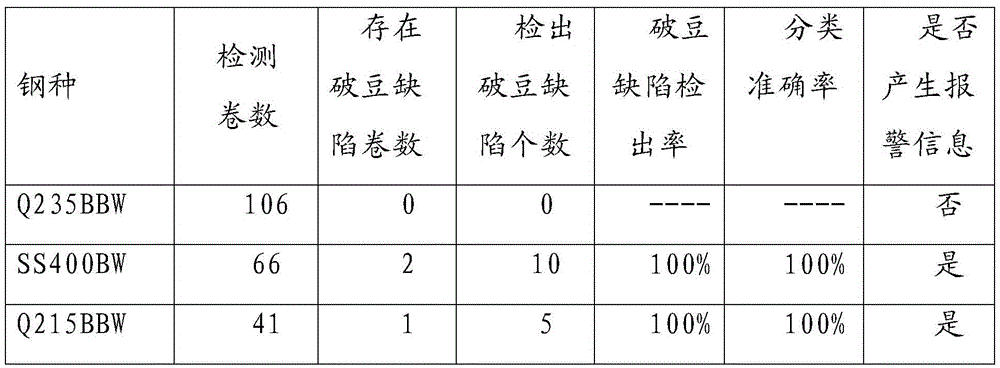

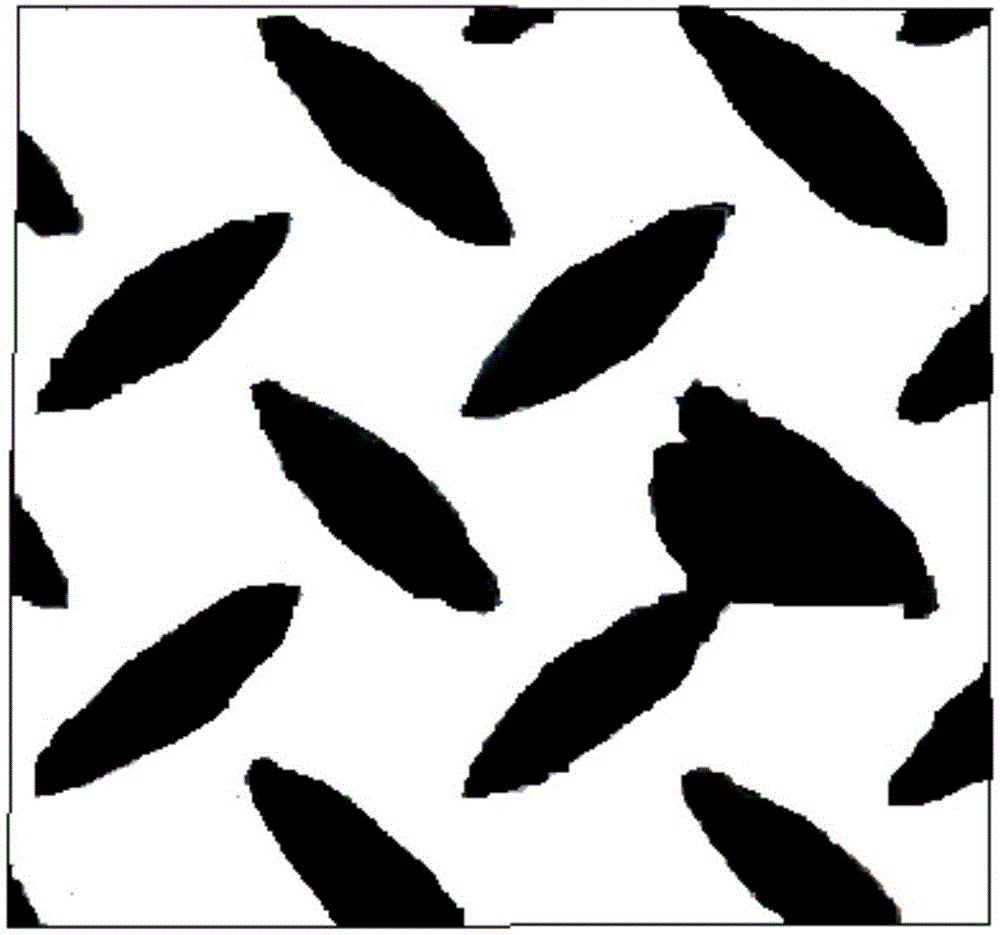

[0019] The embodiment of the present invention provides a detection device for the broken bean defect of the pattern plate of the hot-rolled PepsiCo surface detection system, including a CCD high-speed camera system, a detection parameter setting module, a classifier, a standard edge detection module, and a special area for traditional hot rolling Detection module, sensitive area detection module and post-processing module. The detection parameter setting module is used to set the parameters of the checkered plate material group. The parameters of checkered plate material group include material property parameters and classifier property parameters. The standard edge detection module is used to set the gray threshold value of checkered plate edge detection. The standard edge detection module is used to find the edge of the strip steel. When the camera shoots, it will capture the edge of the strip steel and the non-strip steel area outside the edge. Setting the critical gray v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com