Enterprise quality management system and method

A quality management and enterprise technology, applied in data processing applications, instruments, resources, etc., can solve problems such as waste of enterprise resources, inability to confirm production problems, affecting the effect of enterprise quality management, etc., to improve systematization and reduce self-examination of problems effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

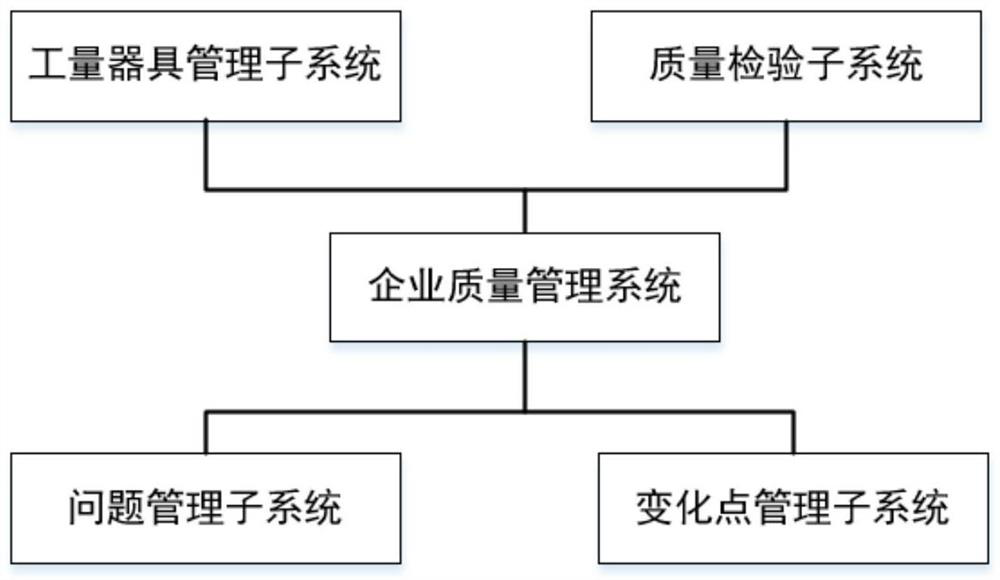

[0037] The embodiment is basically as attached figure 1 Shown: An enterprise quality management system, including quality inspection subsystem, problem management subsystem, measuring instrument management subsystem and change point management subsystem; quality inspection subsystem, problem management subsystem, and measuring instrument management subsystem and the change point management subsystem communicate with each other.

[0038]The quality inspection subsystem is used to inspect each manufacturing process. Specifically, the quality inspection subsystem includes inspection functions such as incoming material inspection, process inspection, factory inspection, and full-scale inspection, and can be applied to various inspection management tasks in the manufacturing process. The quality inspection subsystem includes a spontaneous inspection module and a task-based inspection module; the spontaneous inspection module is used for personnel to create inspection tasks spontan...

Embodiment 2

[0055] An enterprise quality management system, on the basis of the first embodiment, a statistical process control subsystem is added. The statistical process subsystem is used to use mathematical analysis methods to conduct comprehensive quality analysis of each equipment and each production link according to the data items collected by other subsystems. Specifically, the statistical process subsystem is provided with a visualization module, which is used to dynamically display the analysis results in the form of SPC charts.

[0056] This embodiment also provides an enterprise quality management method. On the basis of the first embodiment, the statistical process subsystem is used, and the mathematical analysis method is used to carry out the monitoring of each equipment and each production link according to the data items collected by other subsystems. Comprehensive quality analysis.

[0057] The enterprise management system and method provided in this embodiment can cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com