Pressure protection system for key equipment of chemical engineering device

A technology for protecting systems and key equipment, applied in sequence/logic controller program control, electrical program control, etc., can solve the problem that high-integrity pressure protection systems rarely use chemical equipment, etc., to improve automatic protection capabilities, High reliability and less malfunction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

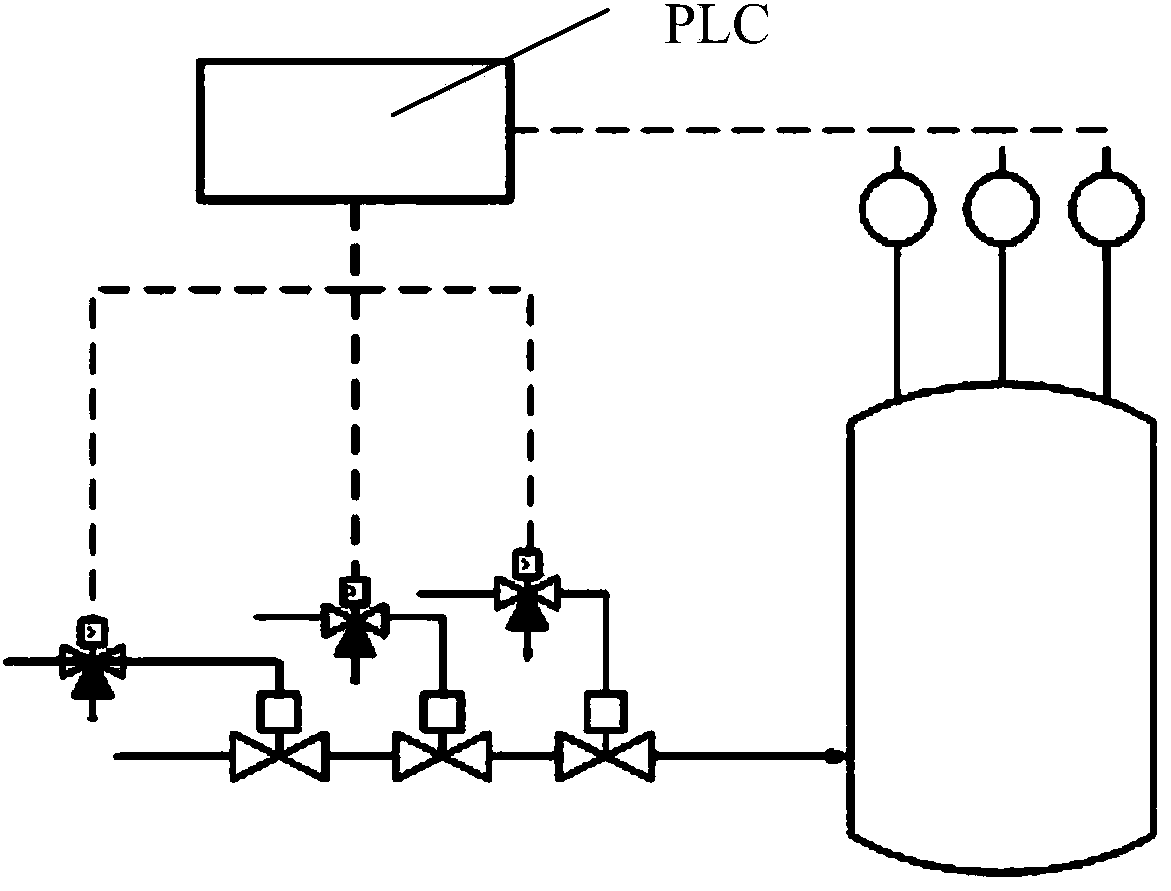

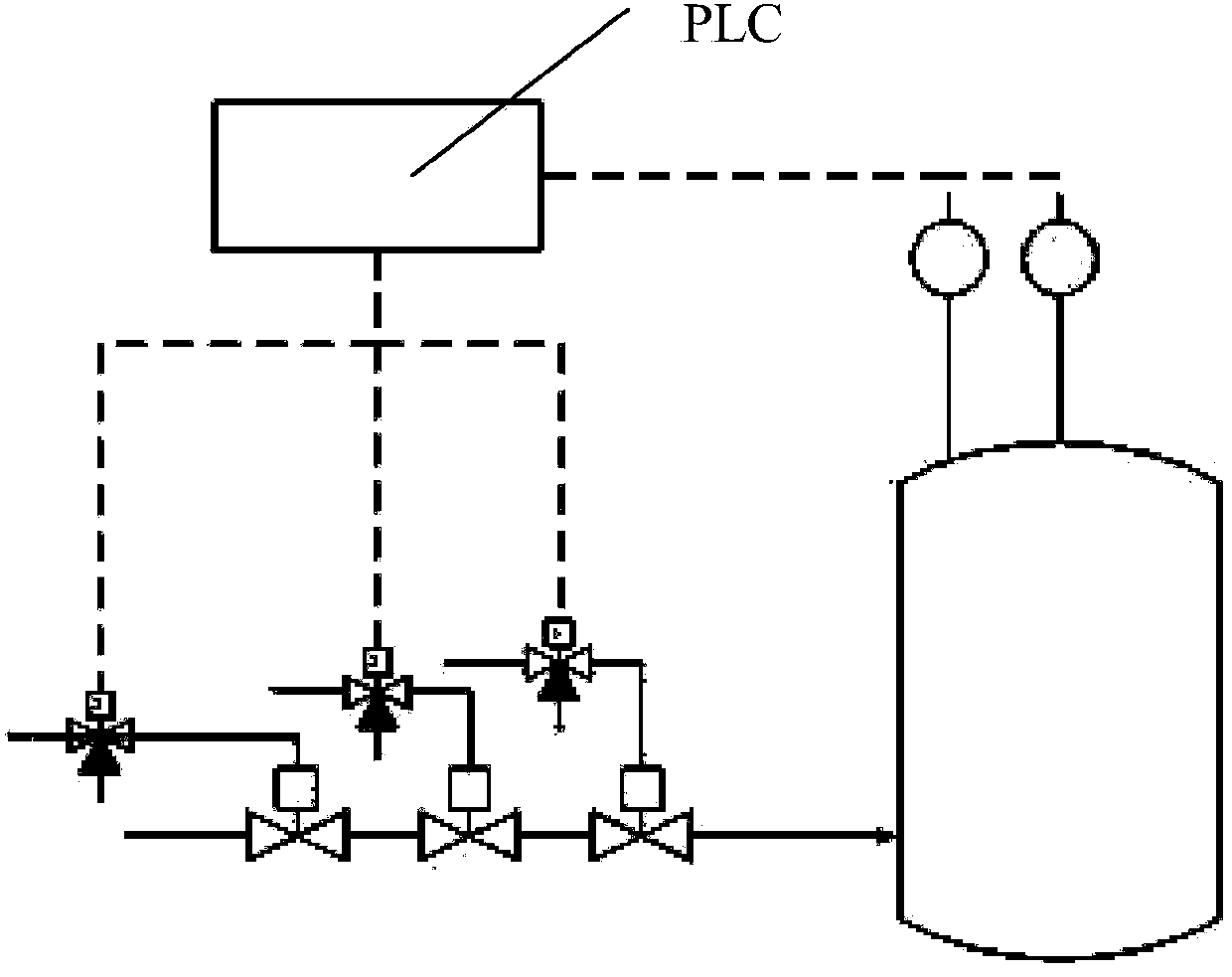

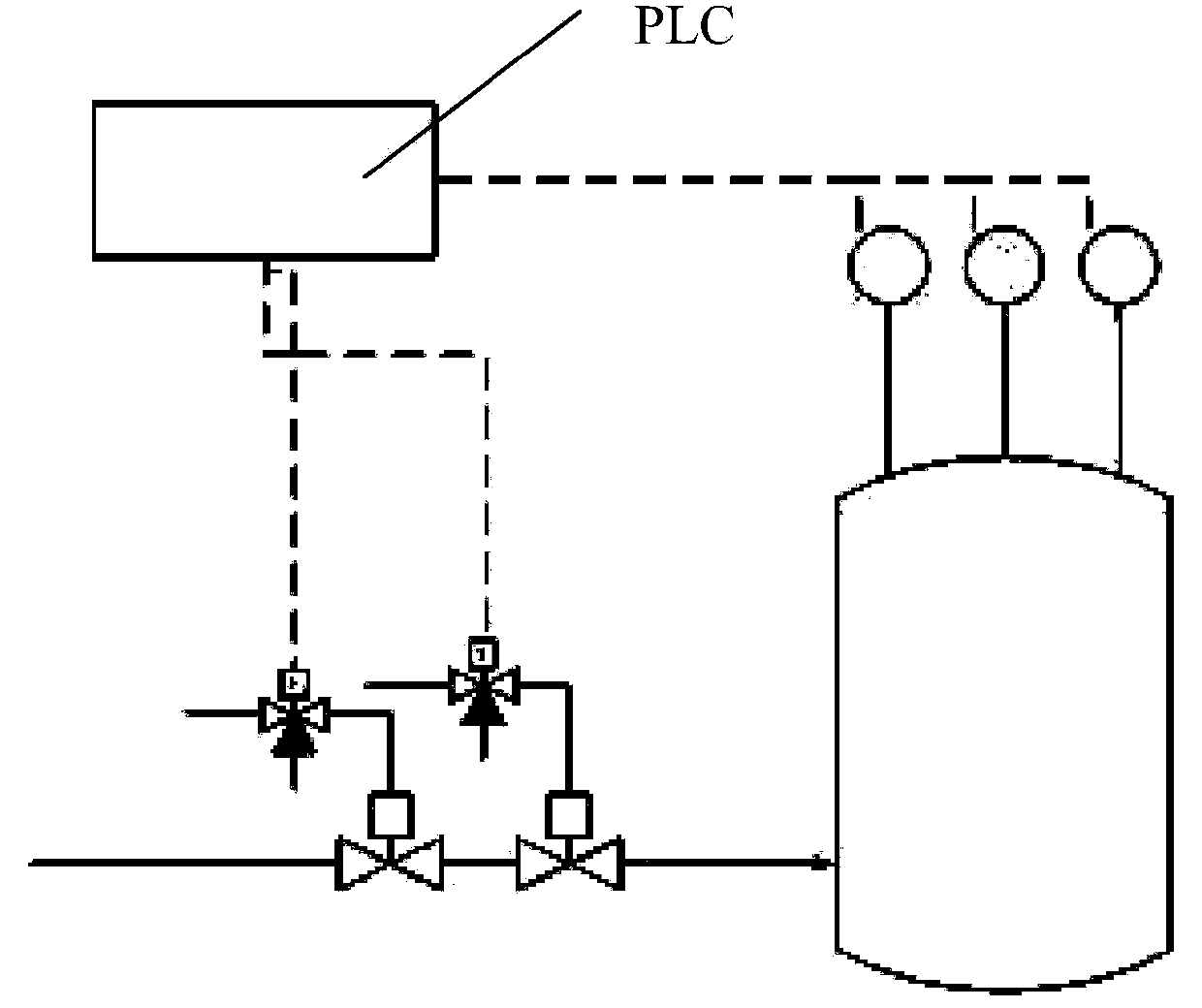

[0026] A pressure protection system for key equipment of a chemical plant includes a safety PLC controller, an isolation circuit, an actuator, a pressure sensor, and an indication and operation panel.

[0027] The safety PLC controller is used to receive the pressure signal of the pressure sensor, make decisions and judgments, control the switch of the actuator, and complete the pressure protection function. A safety PLC with a higher SIL level is used to prevent misoperation and control failure.

[0028] The safety PLC controller includes dual redundant power supplies, triple redundant CPUs, dual redundant I / O cards and dual redundant communication components.

[0029] Further, the safety PLC controller is only composed of the above components.

[0030] The pressure sensor collects field signals, which are input to the controller through the isolation circuit, and control commands are output to the actuator through the isolation circuit, so as to realize safety protection und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com