A kind of led packaging structure

A technology of LED packaging and sealing layer, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of high cost, poor yield, small LED lamp beads not making high-density static screens, etc., to achieve a small footprint , the effect of small spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

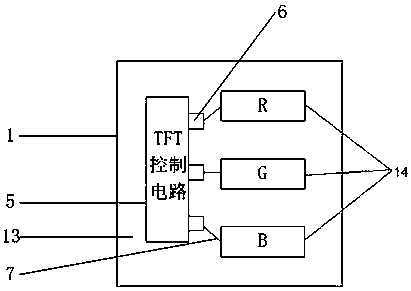

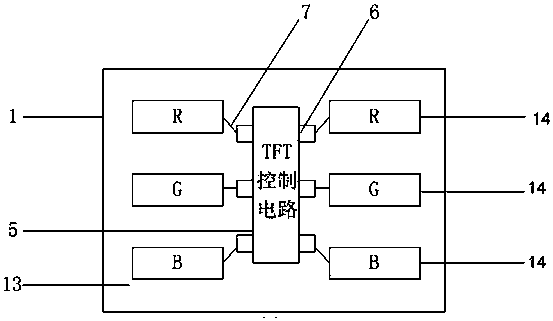

[0023] Such as figure 1 As shown, it is a structural schematic diagram of a specific embodiment of an LED packaging structure according to the present invention. see figure 1 In this specific embodiment, an LED packaging structure includes at least one set of LED light-emitting chips 14, a PCB board 13, and a TFT control circuit module 5 for controlling at least one set of LED light-emitting chips 13, and the TFT control circuit module 5 and at least one set of LED light-emitting chips. The light-emitting chip 14 is packaged on the PCB board 13 to form a COB structure, the TFT control circuit module 5 is provided with electrodes 6 connected to at least one group of LED light-emitting chips 14, and the TFT control circuit module 5 and at least one group of LED light-emitting chips 14 are formed with a package. glue layer.

[0024] In this specific embodiment, the TFT (Thin Film Transistor, Thin Film Transistor) control circuit module 5 is integrated into the LED light-emittin...

Embodiment 2

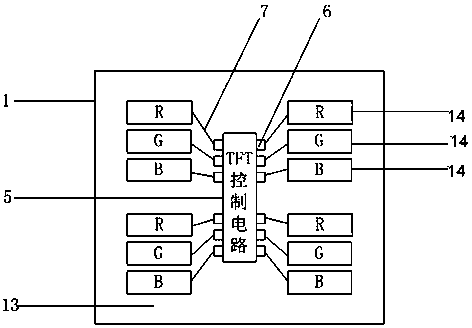

[0033] The difference between this embodiment and Embodiment 1 is that the TFT control circuit module 5 only includes a TFT matrix control circuit, and then the TFT matrix control circuit is directly fabricated on the PCB board 13 and connected with at least one group of LED light-emitting chips, so that the PCB board 13 Possesses functions of TFT control circuit such as Figure 7 shown. Compared with Embodiment 1, this embodiment does not need a substrate for integrating the TFT control circuit module 5, but makes the TFT matrix control circuit on the PCB board 13, thereby reducing the manufacturing process of the TFT matrix control circuit module and improving production. High efficiency reduces the cost of production, and because it is not limited by the substrate, it can more effectively reduce the distance between the TFT control circuit module 5 and the LED light-emitting chip, so as to make full use of the space and increase the arrangement density to achieve higher res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com