Tobacco roller far infrared composite dying experimental equipment

A technology of composite drying and experimental equipment, applied in the directions of tobacco, tobacco preparation, drying gas layout, etc., can solve the problem of low filling value of products, improve material utilization rate, increase heat exchange area, and reduce material crushing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

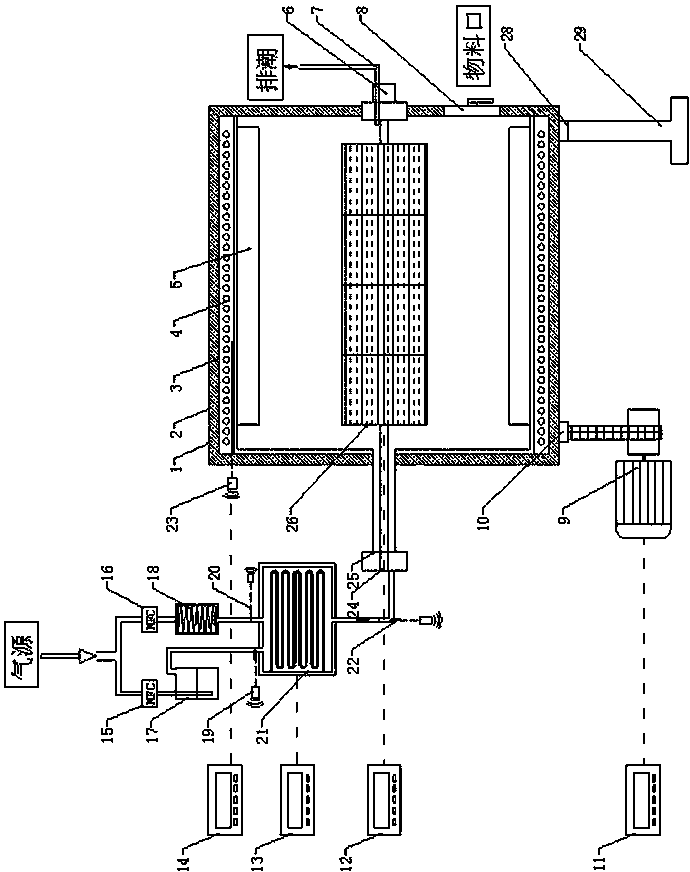

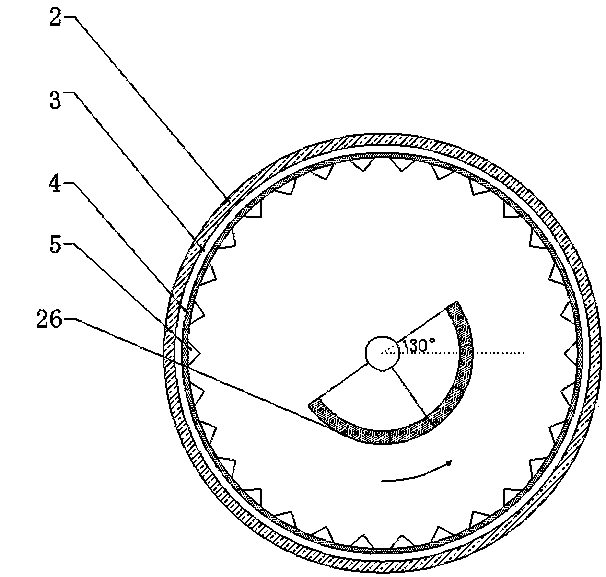

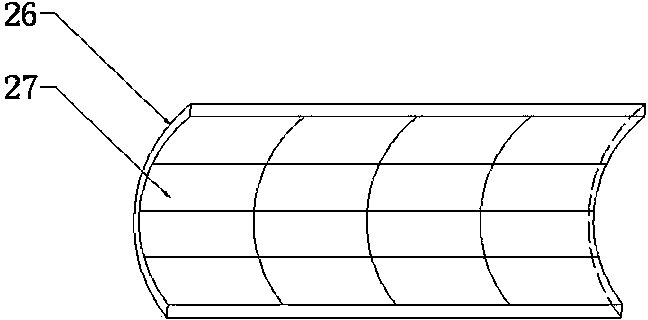

[0029] like figure 1 Shown: a tobacco drum far-infrared composite drying experimental equipment, including a horizontal drum 1 with a central shaft 24 driven by a frequency conversion motor 9, a hot air delivery system connected to the drum, and a remote drum installed in the inner cavity of the drum. The infrared heating device is provided with a heating layer 3 and a thermal insulation layer 2 sequentially on the wall of the drum, and a material lifting board 5 is fixed on the inner cavity wall 4 of the drum. The hot air conveying system includes a gas source, a gas preheating Heater 18, steam generator 17, heat exchanger 21 and the gas pipeline leading into the inner cavity of the drum; the far-infrared heating device 26 is a semicircular heating panel that adopts ceramic far-infrared radiation plate 27 to form, and the heating panel The radiation power of the drum is adjustable, and a material port and a moisture discharge pipe 7 are provided on the rear end wall of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com