Band type linear vibrating screen

A technology of linear vibrating sieve and screen mesh, which is applied in the direction of filter screen, solid separation, grid, etc., and can solve the problems that cannot be taken into account at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

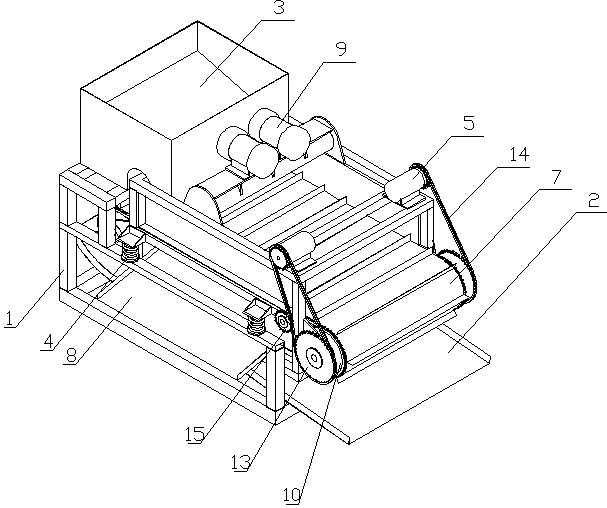

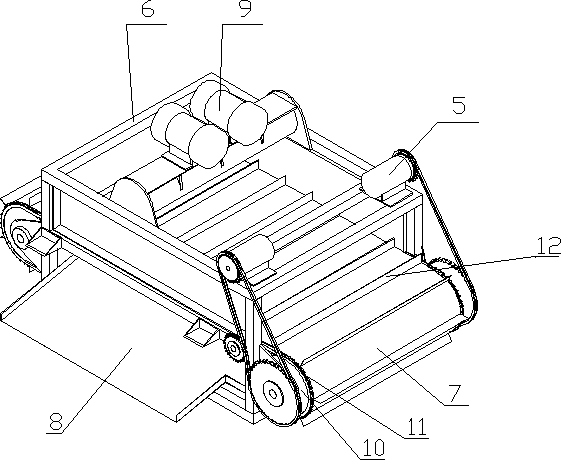

[0015] The belt type linear vibrating screen includes a base 1, a screen body, a lower diversion groove 2 and a feed box 3. A sieve body is installed on the base 1 through a support spring 4, and a lower diversion groove 2 is installed on the base 1 below the sieve body; a feed box 3 is installed on the base 1 at one end of the sieve body.

[0016] The screen body of the belt-type linear vibrating screen is composed of a speed-regulating transmission motor 5 , a screen support 6 , a belt screen 7 , an upper diversion groove 8 and an excitation motor 9 . The front and rear ends of the screen support 6 are symmetrically installed with a screen sprocket 10 respectively through the transmission shaft, and a belt screen 7 is installed on the screen sprocket 10 through a screen chain 11, and the belt screen 7 is arranged at intervals. There are baffles 12 to divide the belt screen 7 into multiple working units (areas) and prevent the mud from rapidly losing from the screen surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com